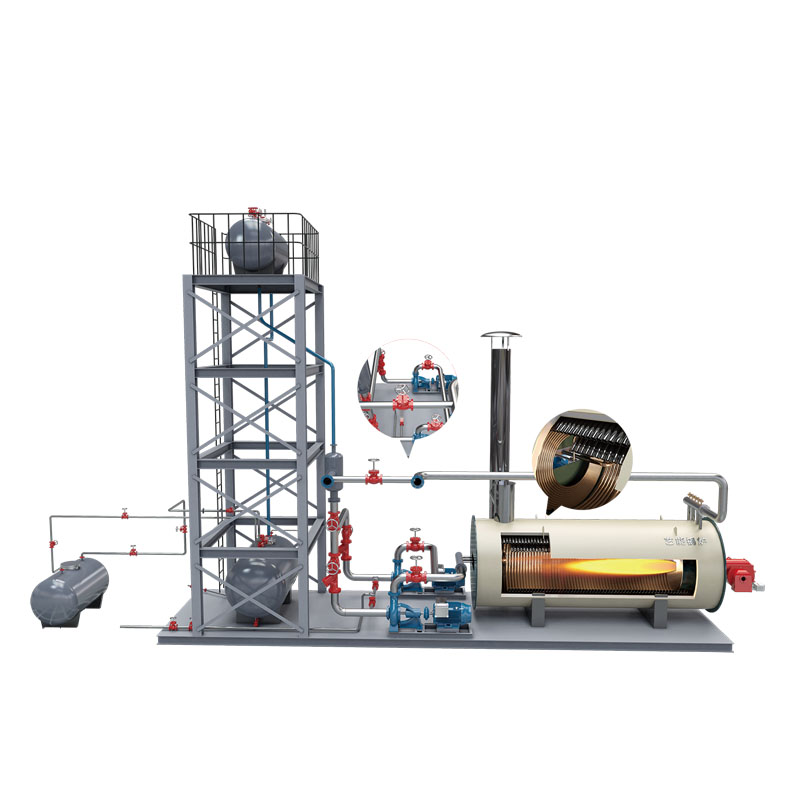

Waste heat boiler (Syngas)

The process gas waste heat boiler (WHB) is a critical piece of equipment cooling the hot synthesis gas exiting an ATR, a secondary reformer, or an SMR. The heat from the process gas is utilized to generate high pressure and high-quality steam for the process and to drive turbines.

Depending on the downstream processes and the need for accurate temperature control, the WHB can be designed with one or two compartments and combined with a steam superheater and/or configured with an internal bypass if required. In this way, a variety of process concepts becomes feasible and can be optimized to suit the specific plant needs.

The TOPSOE™ WHB is based on a thin flexible tube sheet combined with a unique thermal protection of the tube sheet, the tube-to-tube sheet weld, and the tube inlet. This protection is essential to avoid long-term degradation of the boiler from high temperatures and highly corrosive gases.

As a synthesis gas producer, you would demand a high reliability of all critical equipment. TOPSOE™ has a long reference list of boilers designed and delivered for even very severe conditions. Our strict manufacturing requirements and quality control ensure that the TOPSOE™ proprietary WHB is robust, reliable, and supports a long life.

Benefits

Heat recovery and temperature control

- The WHB ensures a high degree of heat recovery producing valuable steam

- Flexibility in configuration to suit process needs

- TOPSOE™’s internal bypass systems are designed to give optimum temperature control, ensuring uniform gas temperatures and to avoid metal dusting corrosion issues

High reliability

- The TOPSOE™ WHB is proven for large single line capacities

- The WHB design features make it possible to operate at high gas temperatures and at low steam-to-carbon ratios

- The design and manufacture of the TOPSOE™ proprietary WHB is based on our intimate understanding of the process challenges and our dedicated efforts in designing and manufacturing high-quality equipment for more than 50 years

-

Hebei Yineng Boiler will attend Shoes & Leather Exhibition- Vietnam 2025NewsJul.01,2025

-

Understanding Waste Heat Boilers: Revolutionizing Energy EfficiencyNewsJun.24,2025

-

Industrial Hot Water Boiler: The Backbone of Efficiency and ReliabilityNewsJun.24,2025

-

Industrial Hot Oil Heater: The Ultimate Solution for Your Thermal NeedsNewsJun.24,2025

-

Horizontal Steam Boiler: The Optimal Solution for Industrial ApplicationsNewsJun.24,2025

-

Electric Steam Boiler for Industrial UseNewsJun.24,2025