WASTE HEAT RECOVERY SYSTEMS

WASTE HEAT RECOVERY SYSTEMS

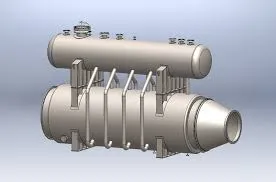

Waste heat recovery systems recover the thermal energy from the exhaust gas and convert it into electrical energy, while the residual heat can further be used for ship services (such as hot water and steam). The system can consist of an exhaust gas boiler (or combined with oil fired boiler), a power turbine and/or a steam turbine with alternator. Redesigning the ship layout can efficiently accommodate the boilers on the ship to better fit these systems.

Waste heat recovery is well proven onboard ships, but the potential can be variable depending on the size, numbers, usage and efficiency of the engines on board. Furthermore, these measures are usually not relevant for retrofitting, due to large costs and efforts related to redesign, steel work, extra weight, etc.

Applicability and assumptions

This technology can be applied to all ships regardless of size, age and type even though it seems to be a practical lower limit on the engine size of 10 MW at present.

The effect is assumed to be constant, as the vessels operating at a high enough engine load when in operation for the power turbine/steam turbine to work efficiently. Note that in reality a slow steaming vessel initially designed for e.g. 80% engine load on main engine would not be able to utilize a power turbine/steam turbine.

The benefit from the measure can be twofold: in terms of reduced fuel consumption on either a main engine equipped with shaft generator or on the traditional auxiliary engines. For simplicity the estimated reduction potential is here given as efficiency gain on the main engine, taking into account this twofold benefit possibility.

Waste heat recovery boiler

Cost of implementation

The installation cost for this measure is estimated at $5,000,000 to $9,500,000 (USD) per ship from the smallest up to the largest installations. There are a lot of costs involved with installing such a system which are more or less independent of size, and a cost element which is modelled linearly with ship size.

There will be some annual maintenance needed, mainly for the boiler, power turbine and/or steam turbine, in order to keep up the performance of the WHR-system. This cost is estimated at around $20,000 (USD) per ship, independent of size, for waste heat recovery systems with steam turbine. For waste heat recovery systems with power turbine $10,000 (USD) is estimated as an annual maintenance cost, and for the combined power and steam turbine system $30,000 (USD) is estimated. It is however recognized that these figures may be in the lower end.

Reduction potential

The reduction potential is estimated at 3% to 8% of main engine fuel consumption.

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025

-

Electric Steam Boiler Manufacturers | Industrial Power & EfficiencyNewsAug.12,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.11,2025