Jan . 23, 2025 05:42

Back to list

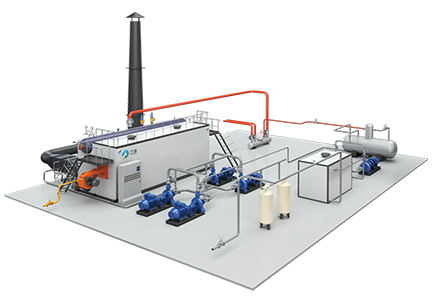

Gas oil fired WNS seires automatic hot water boiler

Exhaust heat in industrial processes, particularly in cement production, signifies untapped potential for energy savings. At the heart of this opportunity lies the waste heat recovery boiler—a technological innovation meticulously designed to capture and repurpose excess thermal energy, contributing to the reduction of operational costs and the enhancement of sustainability in cement plants.

The authoritativeness of deploying waste heat recovery boilers is backed by numerous successful case studies and empirical research. Reports indicate that cement plants that have adopted these systems are achieving upwards of 20% energy efficiency improvements. Furthermore, industry analysts and environmental experts endorse the technology not merely as an optional enhancement but as a requisite step towards sustainable industrial evolution. Trustworthiness is an intrinsic value when considering the adoption of such technology in a cement plant. Leading manufacturers and providers of waste heat recovery solutions exhibit robust credentials, complete with certifications from internationally recognized standards organizations. The rigorous testing and adherence to global best practices in manufacturing confirm the reliability and durability of these systems. Additionally, after-sales support extends beyond traditional customer service, encompassing comprehensive training programs and maintenance schedules that ensure these systems operate seamlessly, maximizing their lifespan and efficiency. Navigating the complexities of energy management in cement production requires a commitment to integrating proven, innovative technologies. Waste heat recovery boilers exemplify this commitment, offering a pathway to substantial energy conservation and sustainability. As the industry faces increasing pressure to adapt to environmental demands, the adoption of these systems is no longer a mere competitive edge but a fundamental aspect of modern industrial operation. By leveraging waste heat recovery, cement plants not only achieve financial and environmental benefits, but they also reaffirm their position as leaders in innovative industry practices, setting a precedent for others to follow.

The authoritativeness of deploying waste heat recovery boilers is backed by numerous successful case studies and empirical research. Reports indicate that cement plants that have adopted these systems are achieving upwards of 20% energy efficiency improvements. Furthermore, industry analysts and environmental experts endorse the technology not merely as an optional enhancement but as a requisite step towards sustainable industrial evolution. Trustworthiness is an intrinsic value when considering the adoption of such technology in a cement plant. Leading manufacturers and providers of waste heat recovery solutions exhibit robust credentials, complete with certifications from internationally recognized standards organizations. The rigorous testing and adherence to global best practices in manufacturing confirm the reliability and durability of these systems. Additionally, after-sales support extends beyond traditional customer service, encompassing comprehensive training programs and maintenance schedules that ensure these systems operate seamlessly, maximizing their lifespan and efficiency. Navigating the complexities of energy management in cement production requires a commitment to integrating proven, innovative technologies. Waste heat recovery boilers exemplify this commitment, offering a pathway to substantial energy conservation and sustainability. As the industry faces increasing pressure to adapt to environmental demands, the adoption of these systems is no longer a mere competitive edge but a fundamental aspect of modern industrial operation. By leveraging waste heat recovery, cement plants not only achieve financial and environmental benefits, but they also reaffirm their position as leaders in innovative industry practices, setting a precedent for others to follow.

Latest news

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Solutions & CustomizationNewsJul.27,2025