waste heat recovery boiler in cement plant exporter

Waste Heat Recovery Boilers in Cement Plants A Key to Sustainability

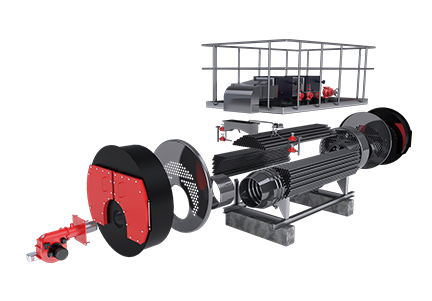

In recent years, energy efficiency and sustainability have emerged as critical priorities for various industries, particularly in the cement sector, one of the most energy-intensive industries worldwide. Cement production generates significant amounts of waste heat, and harnessing this heat presents a tremendous opportunity for reducing energy consumption and mitigating environmental impact. Waste heat recovery (WHR) boilers have become essential components in modern cement plants, enabling the recovery of this otherwise lost heat and converting it into usable energy.

Waste heat recovery boilers utilize the high-temperature flue gases produced during cement manufacturing processes, such as calcination and clinker production. These gases, which typically contain thermal energy that would be vented to the atmosphere, can be redirected into WHR boilers where they pass through heat exchangers. Here, the waste heat is converted into steam, which can be used to power turbines for electricity generation or for various heating applications within the plant. This process not only enhances the overall energy efficiency of cement production but also contributes significantly to cost savings and reduced greenhouse gas emissions.

The integration of waste heat recovery systems in cement plants offers several benefits. First and foremost, it reduces reliance on traditional fossil fuels by utilizing waste heat, which is a renewable energy source. This transition not only lowers fuel costs, but also helps companies meet stringent regulations regarding emissions and carbon footprints. Furthermore, using WHR systems can improve a plant's operational efficiency, leading to more consistent production outputs and the potential for expanded capacity without additional fuel consumption.

waste heat recovery boiler in cement plant exporter

In addition to economic advantages, the use of waste heat recovery boilers aligns with global efforts towards more sustainable industrial practices. With the increasing pressure on industries to minimize environmental impact, the cement sector is responding by investing in technologies that promote energy efficiency and resource recovery. The implementation of WHR systems is both an innovative and responsible approach to address the challenges associated with climate change and energy scarcity.

Moreover, the demand for waste heat recovery boilers is rising globally, leading to a growing market for specialized firms that design and manufacture these systems for the cement industry. Exporters of WHR technologies play a vital role in facilitating the spread of these sustainable solutions, making it possible for plants worldwide to tap into the potential of waste energy recovery.

In conclusion, waste heat recovery boilers represent a pivotal advancement in the quest for sustainable cement production. By capturing and utilizing waste heat, cement plants can significantly reduce energy consumption, lower operational costs, and contribute to environmental sustainability. As the industry continues to evolve, the role of WHR technologies will be increasingly prominent, helping to shape a more efficient and eco-friendly future for cement manufacturing. The integration of these systems not only reflects a commitment to innovation but also highlights the industry's responsibility to embrace practices that ensure the planet's health for generations to come.

-

Industrial Electric Steam Boiler Manufacturers | Efficient SolutionsNewsAug.08,2025

-

Industrial Electric Steam Boilers | Top Manufacturers & SuppliersNewsAug.07,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025