Properly Installed Steam Boilers for Optimal Performance and Reliability in Industrial Applications

The Importance of a Well-Installed Steam Boiler

A steam boiler is a crucial component in various industries, supplying the necessary steam for heating, power generation, and industrial processes. The efficiency and safety of these boilers largely depend on their installation. A well-installed steam boiler not only enhances performance but also minimizes operational costs and maximizes safety. This article explores the significance of a meticulously installed steam boiler and the critical factors involved in the installation process.

Efficiency and Performance

The primary purpose of a steam boiler is to convert water into steam, which can be used for heating or to drive turbines for electricity generation. A well-installed boiler optimizes this conversion process, ensuring that heat is effectively transferred to the water. Proper insulation, efficient connection to the steam distribution system, and correct sizing all contribute to achieving maximum efficiency. If the boiler is not installed correctly, energy losses can occur, leading to increased fuel consumption and higher operational costs.

Safety Considerations

Safety is paramount when dealing with high-pressure systems like steam boilers. An improperly installed boiler can pose significant risks, including explosions, leaks, and physical injuries to personnel. Compliance with local regulations and industry standards is essential during the installation process. Qualified professionals must perform the installation, ensuring that safety valves, pressure gauges, and emergency shut-off systems are properly integrated and functional. Regular inspections and maintenance can further enhance safety, providing peace of mind to operators and stakeholders.

Installation Factors

Several key factors must be considered during the installation of a steam boiler

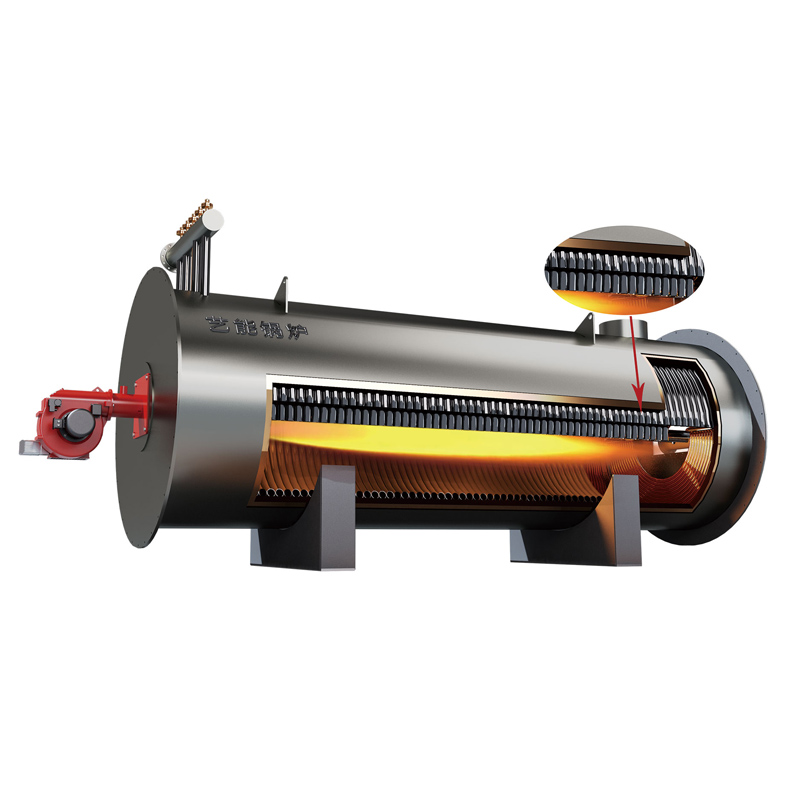

well installed steam boiler product

1. Location The placement of the boiler is vital. It should be installed in an area with adequate ventilation, away from combustible materials, and with sufficient access for maintenance. The structure must also support the weight of the boiler and associated equipment.

2. Sizing Selecting the right size boiler is crucial for ensuring it meets the facility's steam demands without excessive energy consumption. Oversizing or undersizing can lead to inefficiencies and increased wear and tear.

3. Piping and Accessories Proper installation of the piping system is essential for transporting steam and condensate without issues. Insulating the pipes can reduce heat loss, and installing the right valves and pumps ensures efficient steam flow and system reliability.

4. Control Systems Modern steam boilers often incorporate sophisticated control systems for monitoring and regulating operations. These systems must be installed correctly for optimal performance and safety, allowing for real-time adjustments based on demand.

Regulatory Compliance

Adhering to local codes and regulations is not just a legal obligation; it is also a best practice that ensures the safe operation of steam boilers. Installation should follow guidelines from authoritative bodies, which often include standards set by organizations such as the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA). Consultation with local authorities during the planning and installation phases is advisable to avoid potential legal issues.

Conclusion

In conclusion, a well-installed steam boiler is a cornerstone of efficiency, safety, and reliability in industrial operations. By paying careful attention to the installation process, including location, sizing, piping, and compliance with regulations, facilities can ensure that their boilers perform optimally while minimizing risks. Investing in a quality installation not only enhances the operational lifespan of the boiler but also contributes to overall productivity and safety in the workplace. Therefore, taking the time to properly install a steam boiler is an investment in both operational efficiency and safety management.

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025