China's Leading Hot Conduction Oil Boiler Solutions for Efficient Thermal Management

Understanding China’s Hot Conduction Oil Boiler Industry

In recent years, the demand for efficient heating systems has surged worldwide, prompting manufacturers to innovate and improve their products. One such advancement has been the development of hot conduction oil boilers, particularly notable in China. These boilers play a crucial role in various industries, including chemical processing, food production, and textiles, where consistent and reliable heating is paramount.

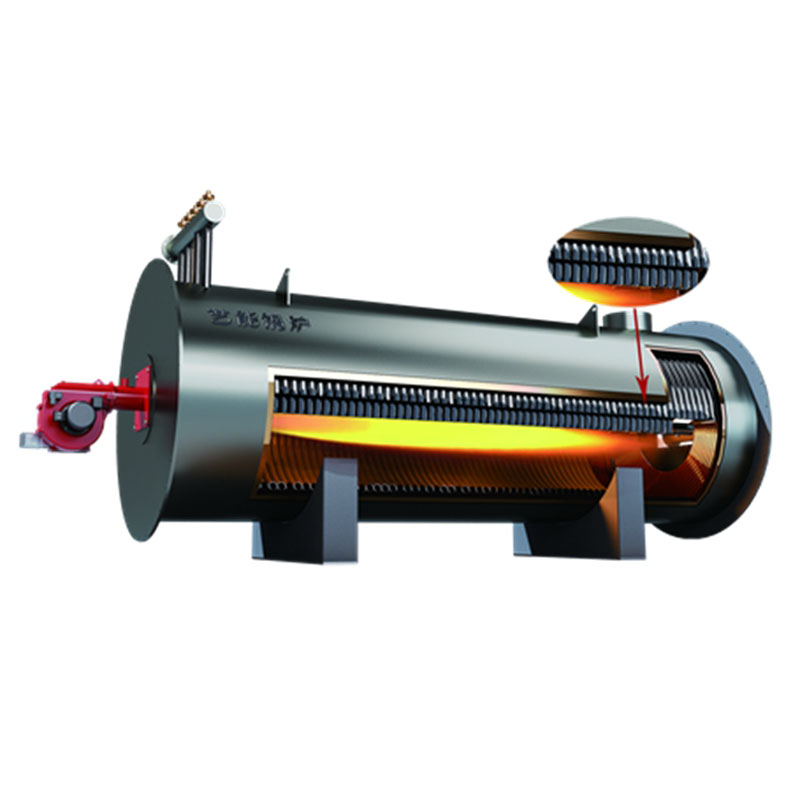

Hot conduction oil boilers operate by using oil as a heat transfer medium instead of water or steam. This unique feature allows for higher operational temperatures and increased efficiency, making them highly desirable for industrial applications. In China, the use of hot conduction oil boilers has grown significantly due to their versatility and ability to enhance productivity across various sectors.

Understanding China’s Hot Conduction Oil Boiler Industry

One major benefit of hot conduction oil boilers is their ability to maintain stable thermal properties at high temperatures. Unlike traditional boilers that face challenges related to scaling and corrosion, conduction oil systems operate efficiently over extended periods without significant degradation. This durability translates to lower maintenance costs and longer service life, making them a cost-effective choice for businesses.

china hot conduction oil boiler

Safety is another critical consideration for any boiler system, and hot conduction oil boilers are designed with robust safety features. These include multiple pressure relief valves, automatic shut-off mechanisms, and state-of-the-art monitoring systems that ensure safe operation under various conditions. As safety standards evolve, manufacturers in China are continually upgrading their systems to comply with global safety regulations, fostering confidence among users.

Moreover, the trend toward environmental sustainability has influenced the hot conduction oil boiler market significantly. Manufacturers are increasingly focusing on producing eco-friendly systems that minimize emissions and energy consumption. The integration of automated controls allows for optimized fuel usage, reducing the carbon footprint associated with industrial heating processes.

The rise of smart technology in the boiler industry is also noteworthy. Many companies are incorporating IoT (Internet of Things) capabilities, allowing for real-time data monitoring and remote control. This advancement not only improves operational efficiency but also empowers users to analyze performance metrics, leading to informed decision-making and reduced operational costs.

In conclusion, the hot conduction oil boiler industry in China is poised for growth, driven by technological advancements, safety enhancements, and a commitment to sustainability. As industries continue to seek efficient and reliable heating solutions, these boilers will likely play an increasingly vital role in meeting the energy needs of a dynamic market. With ongoing innovations and a focus on quality, Chinese manufacturers are set to remain leaders in this specialized sector, contributing significantly to both national and global industrial progress.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025