discount boiler for rubber

Understanding Discount Boilers for Rubber Production

In the world of manufacturing, particularly within the rubber industry, efficiency and cost-effectiveness are key components that can significantly impact a company's bottom line. One of the critical elements in rubber production processes is the use of boilers. These systems are vital for providing the necessary steam and heat required for various stages, including vulcanization, a process that enhances the durability and elasticity of rubber. With this understanding, it becomes evident why many manufacturers seek discount boilers tailored specifically for rubber production.

What Are Discount Boilers?

Discount boilers refer to heating systems offered at reduced prices, often due to manufacturer promotions, surplus stock, or technological advancements leading to improved models. For rubber manufacturers, investing in a discount boiler can be an excellent way to reduce operational costs without compromising on efficiency. These boilers work, generating steam or hot water needed for production processes, and can significantly mitigate energy expenses when selected correctly.

Types of Boilers in Rubber Production

Several types of boilers can be utilized in rubber processing, including fire-tube, water-tube, and electric boilers. Each type has its advantages

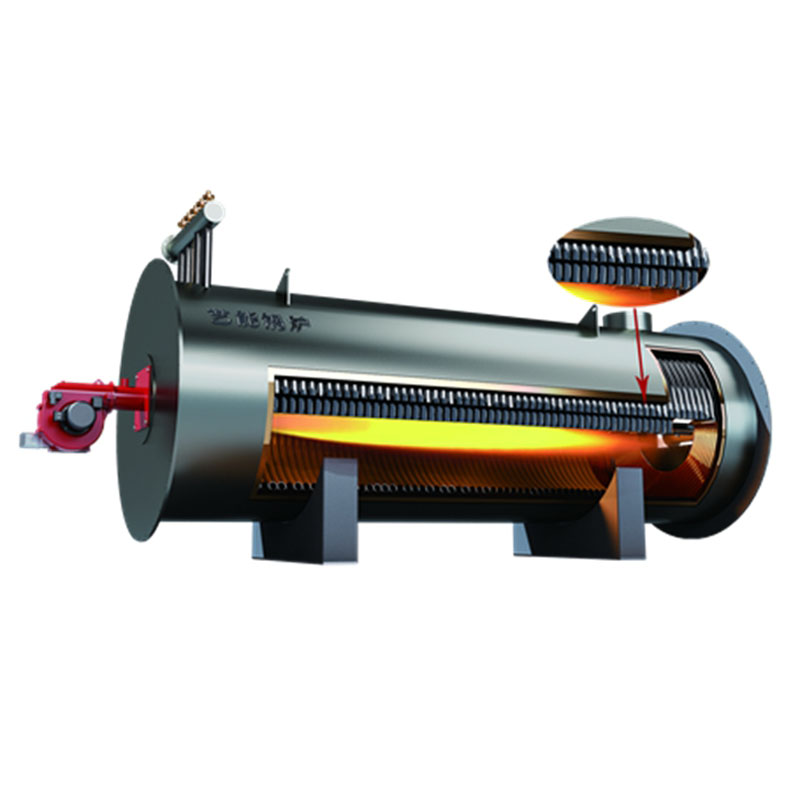

1. Fire-Tube Boilers These boilers are typically more affordable and simpler in design. They are suitable for smaller operations where steam demand is not excessively high.

2. Water-Tube Boilers These are more efficient, offering higher pressure and steam generation in a compact design. They are often used in larger rubber manufacturing facilities.

3. Electric Boilers For operations that are looking to cut emissions or operate in limited spaces, electric boilers provide a clean and efficient alternative, though they can have higher operational costs depending on local electricity prices.

When looking for discount boilers, it's essential for rubber manufacturers to evaluate their specific needs, including steam pressure, capacity, and energy efficiency, to choose the most appropriate system.

Benefits of Purchasing Discount Boilers

discount boiler for rubber

1. Cost Savings Discount boilers can offer significant savings in the initial investment. By selecting the right boiler at a discounted rate, manufacturers can allocate more capital toward other business areas, such as research and development or workforce training.

2. Energy Efficiency Many modern boilers, even when offered at a discount, incorporate advanced technology that improves energy efficiency. This leads to lower utility bills, which is a compelling reason to consider purchasing a new boiler.

3. Reliability and Performance Many discount boilers come from reputable manufacturers, ensuring that they meet industry standards. Investing in a reliable boiler helps prevent disruptions in production, maintaining workflow and output levels.

4. Upgradable Features Some discounted boilers may feature upgradable components, allowing manufacturers to enhance their systems as technology advances or as production needs change.

Considerations When Purchasing Discount Boilers

While the allure of buying a discount boiler can be strong, it is essential to approach this investment with due diligence. Potential buyers should consider

- Supplier Reputation Ensure that the supplier has a solid reputation for quality and service. Research customer reviews and testimonials.

- Warranty and Support Check what warranties offer on the boiler and the availability of customer support for maintenance and troubleshooting.

- Energy Regulations Make sure that the boiler complies with local regulations and standards regarding energy efficiency and emissions.

- Installation and Maintenance Costs Consider the total cost of ownership, including installation and ongoing maintenance, when assessing the affordability of a discounted boiler.

In conclusion, discount boilers can provide a viable solution for the rubber manufacturing industry, promoting cost savings and efficiency improvements. By carefully evaluating their options and selecting a model that meets their specific production needs, manufacturers can significantly enhance their operations while staying within budget. As the rubber industry continues to evolve, investing in the right equipment is crucial for success and competitiveness in the market.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025