Hot Press Machine Boiler Cost Estimates and Supplier Information

Boiler for Hot Press Machine An Essential Component for Efficient Operation

In the realm of manufacturing, machinery plays a pivotal role in ensuring efficiency and quality in production processes. One such machine that is crucial in various industries is the hot press machine. This machine is widely used for bonding materials, laminating surfaces, and shaping products using heat and pressure. A critical component of the hot press machine that often goes unnoticed is the boiler. This article explores the importance of boilers in hot press machines, their functions, and what to consider when sourcing quotes for boilers.

Understanding the Role of Boilers

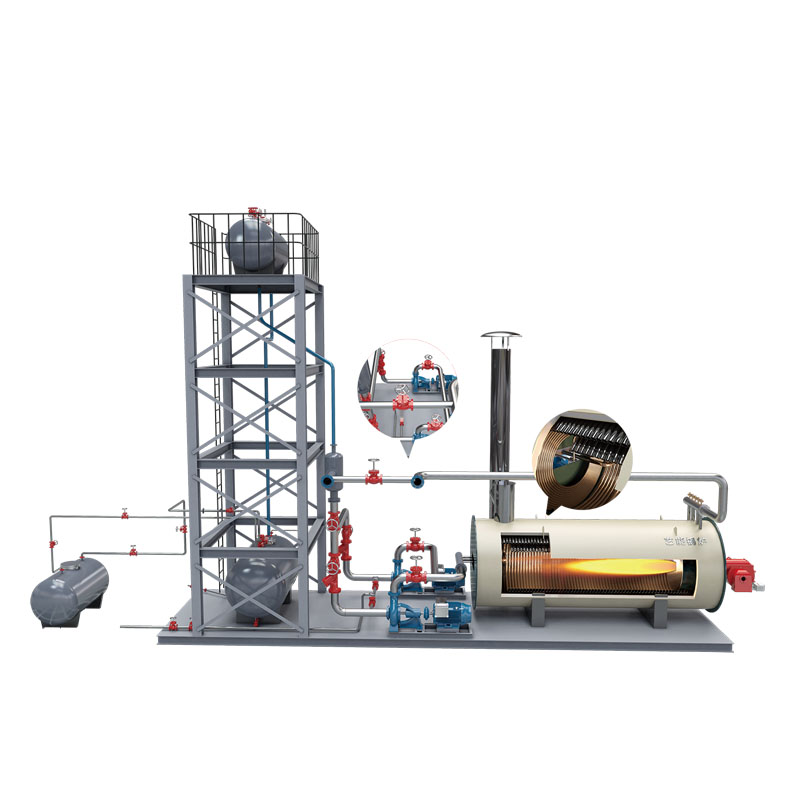

Boilers are essential in generating steam or hot water, which is used in the heating process of a hot press machine. The heat produced by the boiler enables the machine to reach the desired temperature necessary for various applications, such as curing adhesives, compressing materials, and plasticizing thermoplastics. The efficiency of a hot press machine, therefore, heavily relies on the performance of its boiler. A well-functioning boiler ensures consistent heat supply, leading to improved product quality and reduced production time.

Types of Boilers Used in Hot Press Machines

There are several types of boilers utilized in conjunction with hot press machines. These include

1. Fire-tube Boilers These boilers are common in many industrial applications due to their robustness and efficiency. They operate by directing hot gases through tubes immersed in water, generating steam for the hot press machine.

2. Water-tube Boilers Unlike fire-tube boilers, water-tube boilers have water circulating through tubes with hot gases surrounding them. They are known for their ability to produce steam quickly and efficiently, making them suitable for high-demand hot press operations.

3. Electric Boilers For operations requiring precise temperature control and lower capacity, electric boilers can be an attractive option. They are compact, easy to maintain, and environmentally friendly, producing no emissions.

4. Biomass Boilers In an era where sustainability is paramount, biomass boilers are gaining popularity. These boilers use organic materials for fuel, providing a renewable energy source and reducing carbon footprint.

boiler for hot press machine quotes

Factors to Consider When Requesting Boiler Quotes

When sourcing quotes for boilers intended for hot press machines, several factors must be taken into account to ensure optimal performance and cost-effectiveness

1. Capacity Requirements Determine the steam or hot water capacity needed for your specific hot press application. An accurate assessment will help in selecting a boiler that meets your production demands without overloading.

2. Fuel Type Depending on your facility's infrastructure and sustainability goals, consider the type of fuel that will be used (natural gas, propane, electricity, or biomass). Each has its advantages and impacts on operational costs.

3. Efficiency Ratings Look for boilers with high efficiency ratings to minimize energy consumption and operational costs. Modern boilers often come with energy-saving features and technologies that can significantly lower heating expenses.

4. Maintenance and Service Analyze the manufacturer's reputation for service and maintenance. A reliable support system can save you time and money in the long run by preventing costly downtimes.

5. Compliance and Safety Standards Ensure that the boiler meets local safety regulations and industry standards. This is critical not only for operational safety but also for avoiding legal pitfalls.

Conclusion

A robust boiler system is integral to the efficient operation of hot press machines. By understanding the role of boilers, the various types available, and the factors to consider when sourcing quotes, manufacturers can enhance their production capabilities and ensure the longevity of their equipment. Investing time and resources in selecting the right boiler can lead to improved performance and significant cost savings in the long run.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025