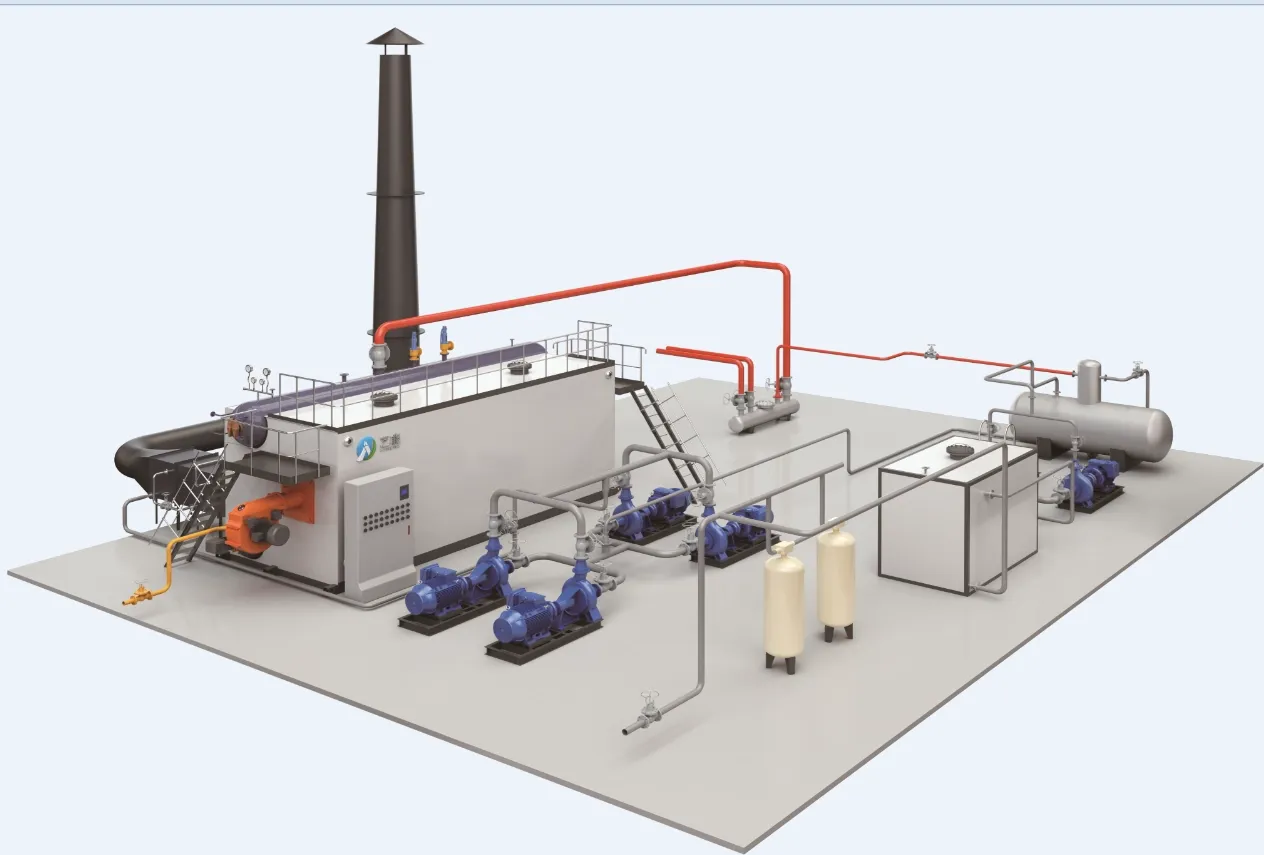

odm steam boiler installation

The Installation of ODM Steam Boilers A Comprehensive Guide

Steam boilers play a pivotal role in various industrial processes, providing the necessary thermal energy to facilitate operations such as heating, power generation, and manufacturing. Among the numerous options available in the market, ODM steam boilers have gained popularity due to their efficiency, durability, and advanced technology. This article delves into the installation process of ODM steam boilers, emphasizing the importance of careful planning, adherence to safety standards, and best practices.

Understanding ODM Steam Boilers

ODM (Original Design Manufacturer) steam boilers are engineered to meet specific requirements of diverse industries, ranging from food processing to chemical manufacturing. These boilers are designed to produce steam at high pressures and temperatures, making them suitable for a wide range of applications. The design and manufacturing processes are tailored to enhance performance, efficiency, and compliance with safety regulations.

Pre-Installation Considerations

Before the physical installation of the steam boiler begins, several preparatory steps must be undertaken.

1. Location Assessment Selecting the right location for the steam boiler is crucial. Considerations such as accessibility, ventilation, proximity to other equipment, and compliance with local regulations must be taken into account. The location should have adequate space for maintenance and potential future expansions.

2. Site Preparation The installation site must be adequately prepared, which includes ensuring that the foundation is level and capable of supporting the weight of the boiler. Appropriate drainage systems should be in place to manage any leakage or overflow.

3. Regulatory Compliance It is essential to verify that the installation complies with local building codes and safety regulations. This may involve obtaining the necessary permits and inspections before proceeding with installation.

Installation Process

odm steam boiler installation

Once the preparatory steps are complete, the actual installation can commence. This process typically involves several key stages

1. Positioning the Boiler The boiler is carefully transported to the site and positioned according to the design layout. This step may require specialized equipment to ensure the boiler is lifted and placed correctly without risk of damage.

2. Connecting Utilities The steam boiler requires connections to various utilities, including water supply, fuel source, and electrical systems. These connections must be made by qualified professionals to ensure safety and efficiency. It is important to install the necessary valves, fittings, and safety devices at this stage.

3. Installing Safety Features Safety is paramount when dealing with steam boilers. Installing pressure relief valves, automatic shut-off systems, and emergency cut-off switches is crucial. These features prevent accidents and ensure the safe operation of the boiler.

4. System Integration Integrating the steam boiler into existing systems is vital. This may involve connecting it with other machinery, steam lines, and monitoring systems to track performance and efficiency. Proper integration ensures that the boiler can operate harmoniously within the overall system.

5. Testing and Commissioning Once the installation is complete, a thorough testing phase must be conducted. This includes checking for leaks, testing safety systems, and confirming that the boiler operates at the required specifications. Commissioning ensures that the boiler is ready for full operation.

Post-Installation Best Practices

After installation, maintaining the performance and longevity of the ODM steam boiler is essential. Regular maintenance checks, including visual inspections and performance testing, can help identify potential issues before they escalate. Scheduling routine maintenance with a qualified technician ensures that the boiler operates safely and efficiently.

Conclusion

The installation of ODM steam boilers is a critical process that requires careful planning, adherence to safety standards, and execution by qualified professionals. By understanding the specific requirements of the installation process and following best practices, industries can harness the benefits of these advanced systems. Proper installation not only enhances operational efficiency but also ensures safety, reliability, and compliance with regulations, ultimately contributing to the success and productivity of industrial operations.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025