Affordable Industrial Boiler Installation Solutions for Cost-Effective Heating Needs

Affordable Industrial Boiler Installation A Comprehensive Guide

When it comes to industrial operations, maintaining an efficient heating system is vital. Industrial boilers are essential for numerous applications, including heating, power generation, and process steam. However, the initial investment for installing a new boiler can be substantial. This article will explore affordable industrial boiler installation, emphasizing cost-effective solutions, considerations, and benefits.

Understanding Industrial Boiler Needs

Before diving into the installation process, it is crucial to assess your specific heating needs. Different industries, such as food processing, petrochemical, or textiles, have varying requirements for temperature and pressure. A thorough analysis will help determine the right type and size of the boiler, which in turn influences installation costs.

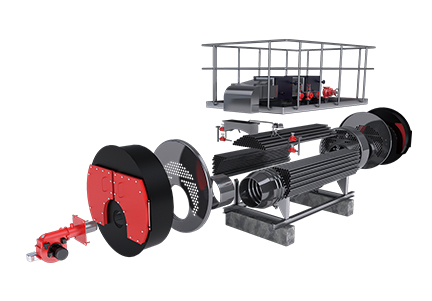

1. Types of Industrial Boilers - Fire-Tube Boilers These are ideal for lower pressure applications and are often more affordable due to their simpler design. - Water-Tube Boilers Better suited for high-pressure applications, water-tube boilers may represent a higher upfront cost but offer efficiency and long-term savings. - Electric Boilers These are increasingly popular due to their simplicity and lower emissions, but the initial investment and operational costs can vary significantly.

Cost Factors in Boiler Installation

The cost of industrial boiler installation can vary widely based on several factors

- Boiler Type and Size As mentioned, different types of boilers come with varying price tags. Selecting the wrong size can lead to inefficiency and increased operational costs. - Installation Complexity The location, existing infrastructure, and the need for retrofitting play a significant role in the overall installation expenses. Complex installations often require specialized labor, which can drive up costs. - Regulatory Compliance Ensuring your system adheres to local regulations may entail additional costs. Consider hiring professionals who can navigate compliance issues effectively.

Finding Affordable Solutions

cheap industrial boiler installation

While the upfront cost for industrial boiler installation can be daunting, there are various strategies to reduce expenses

1. Budget Planning Establishing a clear budget before beginning the selection and installation process can help avoid unexpected costs later on. Factor in installation, maintenance, and operation costs into your budget.

2. Vendor Comparisons Obtain multiple quotes from various vendors to ensure competitive pricing. This step might reveal significant differences in both pricing and service quality.

3. Consider Used Equipment Purchasing a refurbished or used boiler can lead to substantial savings. Ensure that a qualified technician inspects the equipment to assess its condition before the purchase.

4. Incentives and Rebates Research potential government incentives or rebates for energy-efficient installations. Many regions promote sustainable practices and offer financial benefits for transitioning to modern systems.

5. Efficiency Upgrades Investing in energy-efficient models may seem costly at first glance, but the long-term savings in fuel and maintenance can offset initial expenditures.

Long-Term Benefits

Choosing an economical boiler installation doesn’t just save money upfront. An efficient boiler can significantly reduce operating costs and environmental impact. Furthermore, modern boilers comply with strict environmental standards, helping organizations avoid fines and penalties.

In conclusion, while affordable industrial boiler installation requires careful planning and consideration of various factors, it is attainable. By understanding the specific needs of your operations, comparing vendors, exploring used options, and investing in efficiency, businesses can efficiently manage initial costs and benefit from an effective heating solution in the long run. Ultimately, the right boiler installation can enhance productivity, maintain regulatory compliance, and lead to significant operational savings.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025