odm steam boiler heat exchanger

Understanding ODM Steam Boiler Heat Exchangers

In today's industrial landscape, efficient heating systems are crucial for optimizing energy consumption and enhancing productivity. One such system that has gained significant importance is the ODM (Original Design Manufacturer) steam boiler heat exchanger. This technology plays a vital role in various sectors, including manufacturing, energy generation, and food processing, providing reliable heat transfer solutions while maximizing efficiency.

What is a Steam Boiler Heat Exchanger?

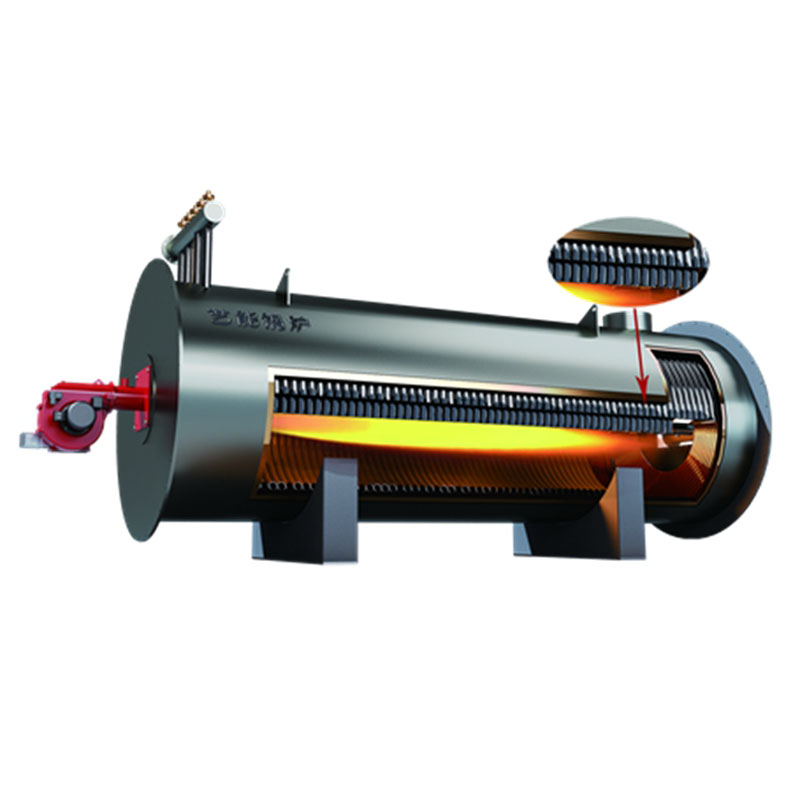

At its core, a steam boiler heat exchanger is a device that transfers heat between two or more fluids without mixing them. In industrial applications, steam boilers generate steam through the combustion of fuels or through electric means, while heat exchangers utilize this steam to transfer heat to another medium—typically water or air. This process is essential for heating processes, generating hot water, and even in power generation cycles.

ODM steam boiler heat exchangers are specifically designed and manufactured by specialized companies, allowing for customization based on the unique requirements of different industries. This customization can involve size, materials, and design configurations, ensuring that the heat exchanger operates efficiently under varying conditions.

Key Benefits of ODM Steam Boiler Heat Exchangers

1. Efficiency One of the primary advantages of ODM steam boiler heat exchangers is their ability to enhance thermal efficiency. They maximize heat recovery, allowing industries to utilize waste heat from steam systems, thus reducing energy consumption and operational costs.

2. Customization As these heat exchangers are designed by original manufacturers, they can be tailored to meet specific industrial needs. This includes adaptations for different temperatures, pressures, and flow rates, ensuring optimum performance.

3. Durability and Reliability ODM manufacturers use high-quality materials and advanced construction techniques to build robust heat exchangers that withstand the rigors of industrial applications. This durability results in reduced maintenance costs and extended equipment lifespan.

odm steam boiler heat exchanger

4. Environmental Impact By improving energy efficiency and reducing fuel consumption, ODM steam boiler heat exchangers contribute to lower greenhouse gas emissions. Industries can achieve their sustainability goals while complying with environmental regulations.

5. Versatility These heat exchangers are highly versatile and can be used in various applications—from preheating feedwater in boilers to cooling steam after it has released its heat. This adaptability makes them essential in numerous industries.

Applications of ODM Steam Boiler Heat Exchangers

ODM steam boiler heat exchangers find applications across a broad array of industries

- Manufacturing They are extensively used in manufacturing processes that require precise temperature control, such as textile production, plastics manufacturing, and chemical processing. - Food and Beverage In this sector, heat exchangers are critical for pasteurization, sterilization, and cooking processes, where they ensure food safety and quality.

- Energy Production Heat exchangers are pivotal in power plants for steam generation and recovery systems, enhancing the overall efficiency of energy production.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these heat exchangers help maintain comfortable temperatures in commercial and industrial buildings.

Conclusion

The ODM steam boiler heat exchanger is a vital component in numerous industrial applications, offering customized solutions that enhance efficiency, reduce operational costs, and minimize environmental impact. As industries strive to meet modern challenges such as energy sustainability and efficiency, the role of these advanced heat exchangers becomes increasingly significant. Investing in high-quality ODM steam boiler heat exchangers not only optimizes heating processes but also supports a more sustainable and economically viable future for industries worldwide.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025