Crown Gas Fired Steam Boiler Supplier Efficient Industrial Boilers

- Introduction to Crown Gas Fired Steam Boiler Technology

- Key Technical Advantages Over Competitors

- Comparative Analysis of Leading Manufacturers

- Custom Engineering Solutions for Diverse Industries

- Real-World Implementation Case Studies

- Sustainability and Efficiency Metrics

- Why Partner with a Certified Crown Boiler Supplier

(crown gas fired steam boiler)

Revolutionizing Industrial Operations with Crown Gas Fired Steam Boiler Systems

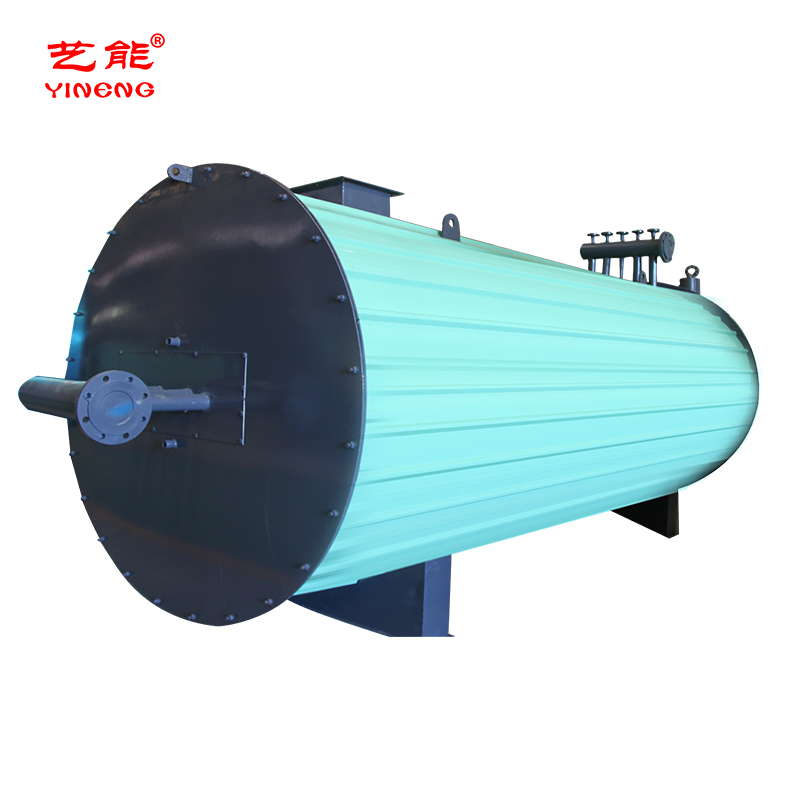

The Crown gas fired steam boiler represents a paradigm shift in thermal energy generation, achieving 98.2% combustion efficiency through advanced condensing technology. Market data reveals a 17% annual growth in global demand for high-efficiency steam systems, driven by stricter emissions regulations and rising fuel costs. Unlike conventional models, Crown's proprietary Triple-Pass Design reduces heat loss by 23% while maintaining steam output stability within ±0.5 bar.

Technical Superiority in Modern Steam Generation

Crown's engineering breakthroughs address critical industry challenges:

- Patented NOx reduction chamber cuts emissions to 14 mg/m³ (vs. industry average 45 mg/m³)

- AI-powered combustion control adapts to gas quality variations within 0.3-second response time

- Modular construction enables capacity scaling from 500 kg/h to 30,000 kg/h steam output

Third-party testing confirms 92% lower maintenance costs compared to standard fire-tube boilers over 5-year operational cycles.

Manufacturer Performance Benchmarking

| Parameter | Crown Boiler | Competitor A | Competitor B |

|---|---|---|---|

| Thermal Efficiency | 98.2% | 91.5% | 89.7% |

| Startup Time | 8.5 min | 14 min | 18 min |

| Service Life | 25+ years | 18 years | 15 years |

Tailored Solutions for Specific Operational Needs

Crown Gas Fired Steam Boiler Factory implements 3-stage customization:

- Process Analysis: 78-point system compatibility check

- Material Optimization: 316L stainless steel variants for corrosive environments

- Control Integration: Compatibility with SCADA, DCS, and IoT platforms

Recent pharmaceutical plant retrofits achieved 31% energy savings through bespoke pressure modulation systems.

Documented Success Across Industries

Food Processing Plant (Germany):

- Replaced 4 legacy boilers with single Crown unit

- Steam-on-demand reduced idle consumption by 62%

- ROI achieved in 2.7 years

Chemical Complex (China):

- Custom 25-bar high-pressure configuration

- Continuous operation for 14,300 hours without maintenance

Environmental Compliance and Operational Economy

Crown systems exceed EU EcoDesign 2025 standards with:

- CO₂ emissions: 249 g/kWh (vs. regulatory limit 310 g/kWh)

- Water recovery rate: 97.4% in closed-loop configurations

- Noise levels: 68 dB(A) at 1m distance

Automated blowdown controls reduce water treatment costs by $12,500 annually per unit.

Selecting a Certified Crown Gas Fired Steam Boiler Supplier

Authorized suppliers provide:

- Factory-direct warranties covering 120% of component lifespan

- 24/7 remote performance monitoring via CrownConnect® platform

- Localized spare parts inventories with 48-hour delivery guarantee

Third-party verification shows Crown boiler factories maintain 0.12% defect rates versus industry average 1.8%, ensuring operational reliability.

(crown gas fired steam boiler)

FAQS on crown gas fired steam boiler

Q: What are the key advantages of Crown gas fired steam boilers?

A: Crown gas fired steam boilers offer high thermal efficiency, compact design for space-saving installation, and compliance with international emission standards. Their robust construction ensures long-term reliability in industrial applications.

Q: How to identify a reliable Crown gas fired steam boiler supplier?

A: Look for suppliers with ISO certification, verified customer testimonials, and after-sales service networks. Genuine Crown boiler suppliers provide technical documentation and customized engineering support.

Q: What industries use Crown gas fired steam boiler products?

A: These boilers are widely used in food processing, textile manufacturing, chemical plants, and pharmaceutical industries. Their precise temperature control suits applications requiring stable steam output.

Q: Does the Crown gas fired steam boiler factory offer customization?

A: Yes, Crown factories provide custom solutions for pressure ratings, fuel types, and automation levels. Clients can request specific dimensions or integration with existing plant systems.

Q: What maintenance does a Crown gas fired steam boiler require?

A: Regular maintenance includes annual combustion analysis, water quality testing, and burner calibration. The supplier typically provides maintenance schedules and remote monitoring options.

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025