Jan . 29, 2025 03:51

Back to list

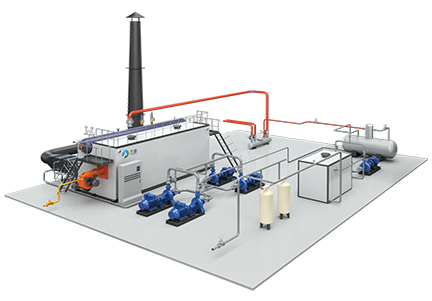

furnace oil fired steam boiler

Furnace oil fired steam boilers are indispensable in industries that require powerful and efficient heating systems. These boilers are celebrated for their ability to generate high-pressure steam, which is vital for a variety of industrial applications, including electricity generation, heating, and even direct mechanical processes. Understanding their operation, advantages, and maintenance is crucial for businesses that aim to optimize their industrial processes.

In terms of authoritative guidance, regulatory bodies have mandated strict emission norms for furnace oil fired boilers, considering the potential environmental impact. Compliance with these regulations is non-negotiable, necessitating advanced emissions control technologies like scrubbers and electrostatic precipitators. This ensures that businesses can keep their carbon footprint in check while benefiting from the high energy yield of furnace oil. The trustworthiness of furnace oil fired steam boilers lies in their proven track record of reliability and consistent performance across various sectors. They are highly favored in industries where uninterrupted steam supply is critical, such as in chemical manufacturing, paper production, and food processing. The ability to provide steady steam pressure and accommodate large load fluctuations makes them indispensable in maintaining operational continuity. To further bolster their trustworthiness, businesses choosing furnace oil fired steam boilers should collaborate with experienced manufacturers and service providers. These partnerships can ensure access to high-quality components, prompt spare parts supply, and technical support tailored to specific operational needs. In summary, furnace oil fired steam boilers remain a crucial asset in various industrial applications, thanks to their efficiency, cost-effectiveness, and adaptability. By prioritizing expertise and diligence in their operation and maintenance, companies can ensure compliance with environmental standards and maximize the benefits of these powerful systems. As industries continue to demand high-performance heating solutions, the role of furnace oil fired steam boilers in meeting these needs is expected to remain significant.

In terms of authoritative guidance, regulatory bodies have mandated strict emission norms for furnace oil fired boilers, considering the potential environmental impact. Compliance with these regulations is non-negotiable, necessitating advanced emissions control technologies like scrubbers and electrostatic precipitators. This ensures that businesses can keep their carbon footprint in check while benefiting from the high energy yield of furnace oil. The trustworthiness of furnace oil fired steam boilers lies in their proven track record of reliability and consistent performance across various sectors. They are highly favored in industries where uninterrupted steam supply is critical, such as in chemical manufacturing, paper production, and food processing. The ability to provide steady steam pressure and accommodate large load fluctuations makes them indispensable in maintaining operational continuity. To further bolster their trustworthiness, businesses choosing furnace oil fired steam boilers should collaborate with experienced manufacturers and service providers. These partnerships can ensure access to high-quality components, prompt spare parts supply, and technical support tailored to specific operational needs. In summary, furnace oil fired steam boilers remain a crucial asset in various industrial applications, thanks to their efficiency, cost-effectiveness, and adaptability. By prioritizing expertise and diligence in their operation and maintenance, companies can ensure compliance with environmental standards and maximize the benefits of these powerful systems. As industries continue to demand high-performance heating solutions, the role of furnace oil fired steam boilers in meeting these needs is expected to remain significant.

Latest news

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025