high quality steam boiler heat exchanger

High-Quality Steam Boiler Heat Exchangers An Essential Component for Efficiency

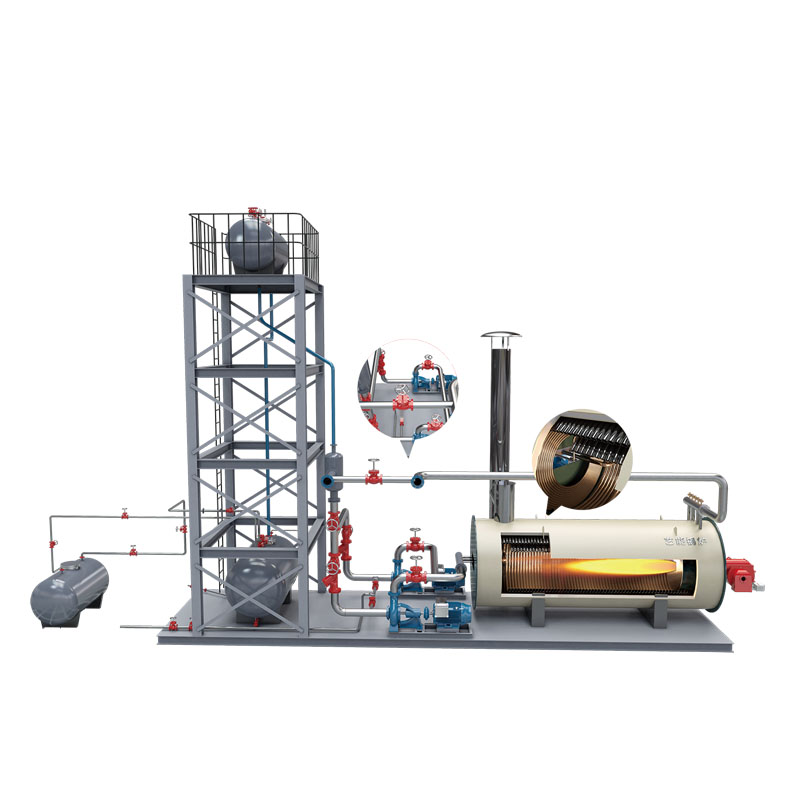

In the realm of industrial heating, steam boilers play a crucial role in providing energy and process heat. At the heart of these systems is the heat exchanger, a vital component that enhances efficiency and performance. High-quality steam boiler heat exchangers not only ensure effective heat transfer but also contribute to the overall sustainability of industrial operations.

A heat exchanger is designed to transfer heat between two or more fluids without mixing them. In steam boilers, this process typically involves water and steam, where the heat from the combustion of fuel is transferred to the water, turning it into steam. The design and material of the heat exchanger significantly impact its efficiency and longevity.

One of the key factors in the performance of a heat exchanger is its surface area. A larger surface area allows for more effective heat transfer, which can lead to higher steam production rates and better energy utilization. Modern heat exchangers often utilize advanced designs, such as finned tubes or plate configurations, to maximize surface area without increasing the unit's footprint.

Material selection is equally important. High-quality heat exchangers are typically made from corrosion-resistant materials, such as stainless steel or specialized alloys, which can withstand high temperatures and pressures. This not only enhances durability but also minimizes maintenance costs over time. A well-constructed heat exchanger will maintain its efficiency and structural integrity, even in harsh operating conditions.

high quality steam boiler heat exchanger

Energy efficiency is a critical concern for industries reliant on steam boilers. High-quality heat exchangers contribute to the reduction of energy consumption by enabling optimal heat recovery. This is particularly relevant in applications where excess steam can be condensed and returned to the boiler. Effective heat recovery systems can lead to significant cost savings and a reduced environmental footprint, aligning with global sustainability goals.

In addition to efficiency, safety is paramount in the design and function of steam boiler heat exchangers. High-quality products are built to meet stringent industry standards and regulations, reducing the risk of failures that can lead to accidents. Properly designed heat exchangers incorporate features like pressure relief valves and temperature sensors, which enhance operational safety.

Furthermore, the choice of steam boiler heat exchangers can impact the overall system performance. Factors such as pressure drop, flow patterns, and maintenance accessibility should be considered during the selection process. Investing in high-quality exchangers can lead to better operational performance, lower downtime, and a more reliable steam generation system.

In conclusion, high-quality steam boiler heat exchangers are integral to the efficiency and safety of industrial heating systems. Their design, material, and function play a significant role in maximizing energy transfer and minimizing operational costs. As industries continue to prioritize sustainability and efficiency, the demand for advanced heat exchangers will only grow, making it imperative for businesses to consider their options carefully. Investing in high-quality heat exchangers is not just a matter of compliance; it is a strategic decision that can yield long-term benefits for both the organization and the environment.

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025