waste heat recovery boiler manufacturers factories

Waste Heat Recovery Boiler Manufacturers Innovations and Impact

Waste heat recovery (WHR) boilers play a crucial role in enhancing energy efficiency across various industrial processes. By capturing and reusing waste heat that would otherwise be lost to the environment, these systems not only reduce overall energy consumption but also minimize greenhouse gas emissions. As industries worldwide strive for sustainability, the importance of waste heat recovery boiler manufacturers has surged, leading to innovations that improve performance and efficiency.

What is a Waste Heat Recovery Boiler?

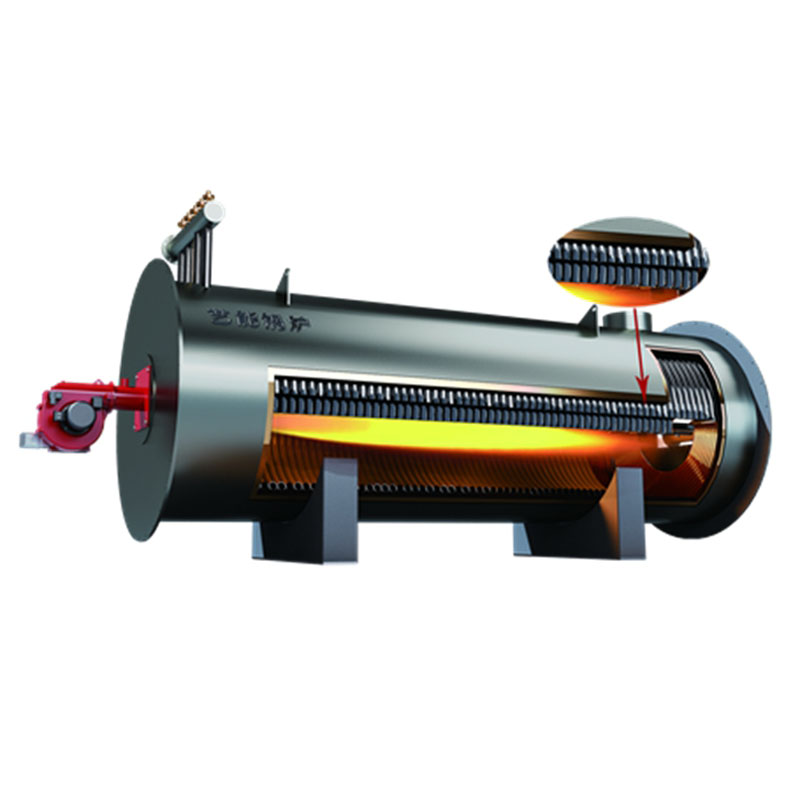

A waste heat recovery boiler is designed to utilize the excess heat generated from industrial processes, such as power generation, petrochemical production, and metal fabrication. This waste heat is typically produced during combustion processes or while manufacturing materials. WHR boilers convert this heat into steam or hot water, which can then be used for various applications, including electricity generation, heating, or as part of a district heating system.

The Role of Manufacturers

Manufacturers of waste heat recovery boilers are at the forefront of this energy efficiency revolution. They employ cutting-edge technologies and materials to design and produce systems that can handle high temperatures and pressures while maximizing heat recovery. This involves using advanced heat exchange designs, such as economizers and air preheaters, which contribute to higher thermal efficiency levels.

Moreover, manufacturers are increasingly focusing on customization. Different industries have unique needs based on the type of waste heat available and the desired end-use of the recovered heat. Leading manufacturers work closely with clients to design bespoke WHR systems that meet specific operational requirements. This collaborative approach not only enhances customer satisfaction but also ensures optimal system performance.

Innovations in Waste Heat Recovery Boiler Manufacturing

Innovation is a constant in the field of waste heat recovery boiler manufacturing. Recent advancements include the integration of digital technologies and IoT (Internet of Things) capabilities. These innovations allow for real-time monitoring and data analysis of system performance, enabling predictive maintenance. By identifying potential issues before they escalate, manufacturers can help clients avoid costly downtimes and improve the longevity of their systems.

waste heat recovery boiler manufacturers factories

Another significant trend in WHR boiler manufacturing is the development of hybrid systems. These systems combine traditional boiler technology with alternative energy sources, such as solar or geothermal energy. This hybrid approach not only maximizes energy recovery but also aligns with global sustainability goals by further reducing reliance on fossil fuels.

Environmental Impact and Energy Efficiency

The environmental benefits of waste heat recovery boilers are substantial. By recovering waste heat, industries can significantly reduce their carbon footprint. According to studies, implementing WHR systems can lead to energy savings of 20-50%, depending on the application and the quality of waste heat available. This reduction in energy consumption translates into lower operational costs and a more sustainable business model.

Additionally, the adoption of waste heat recovery technology contributes to national and global energy efficiency targets. As governments impose stricter regulations and set ambitious goals for reducing greenhouse gas emissions, industries equipped with WHR systems will be better positioned to meet these challenges.

Choosing the Right Manufacturer

When selecting a waste heat recovery boiler manufacturer, several factors should be considered. It is essential to evaluate the manufacturer's experience and reputation in the industry. A company with a proven track record and positive client testimonials can provide assurance of quality and reliability.

Furthermore, potential clients should discuss the range of customization options available, as well as the manufacturer's commitment to innovation and sustainability practices. Engaging with manufacturers who prioritize research and development can lead to the discovery of more efficient solutions tailored to specific operational contexts.

Conclusion

Waste heat recovery boiler manufacturers play a vital role in transforming wasted heat into valuable energy. With their innovative designs, commitment to sustainability, and focus on efficiency, these manufacturers contribute to a more energy-conscious industrial landscape. As industries continue to evolve, the demand for advanced waste heat recovery solutions is expected to grow, underscoring the importance of collaboration between manufacturers and their clients in creating a more sustainable future.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025