oil heater for hot press machine supplier

Understanding Oil Heaters for Hot Press Machines Essential Insights for Buyers

In the world of industrial manufacturing, the hot press machine plays a critical role in processes ranging from woodworking to construction materials. One of the key components that enhance the efficiency of these machines is the oil heater. As industries strive for improved productivity and quality, understanding the function and benefits of oil heaters becomes essential.

What is an Oil Heater?

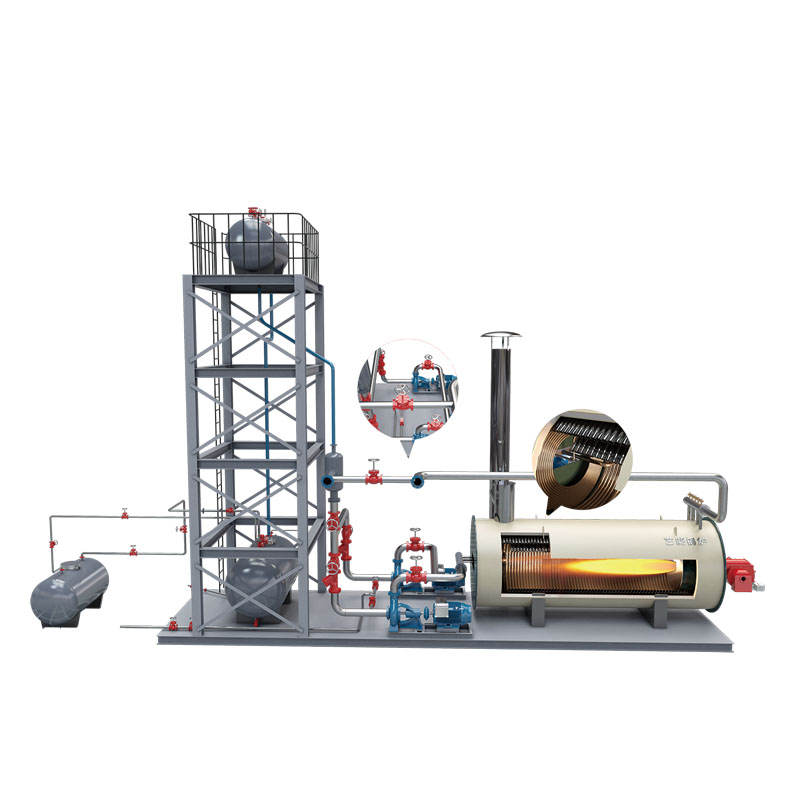

An oil heater is specifically designed to heat fluids in various industrial applications. In the context of hot press machines, it serves the primary purpose of providing consistent and controlled heat to the press. The operation typically involves heating oil, which in turn transfers its thermal energy to the pressing plates. This uniform heat distribution is crucial for achieving high-quality outputs, whether it’s laminated wood products or composite materials.

Benefits of Oil Heaters in Hot Press Machines

1. Efficiency Oil heaters provide superior heat transfer compared to traditional heating systems. The thermal conductivity of oil allows for quick and efficient heating, drastically reducing the time required for the hot pressing process.

2. Temperature Control Precise temperature regulation is vital in hot pressing applications. Oil heaters are equipped with advanced control systems that ensure a stable temperature, preventing overheating and ensuring that the materials achieve the desired specifications.

3. Energy Savings With an effective oil heating system, manufacturers can achieve significant energy savings. The efficient nature of oil heaters means that less energy is required to maintain high temperatures, which translates into cost savings over time.

4. Durability Oil heaters are designed to operate under demanding conditions. Their robust construction ensures they can withstand high temperatures and pressures, making them a reliable choice for continuous operation in hot press machines.

5. Low Maintenance Compared to other heating methods, oil heaters require less maintenance. Regular inspections and oil changes are typically enough to keep these systems operational, thereby minimizing downtime.

oil heater for hot press machine supplier

Choosing the Right Oil Heater Supplier

When selecting an oil heater for your hot press machine, it’s essential to consider various factors to ensure you partner with a reliable supplier. Here are several tips to guide your decision

1. Industry Experience Look for a supplier with a proven track record in providing heating solutions for industrial applications. Experienced suppliers are more likely to understand the unique requirements of your hot press machine.

2. Quality Certifications Ensure that the supplier’s products meet industry standards and have the necessary certifications. This is a good indicator of their commitment to quality and safety.

3. Technical Support Choose a supplier that offers strong technical support. Whether it’s installation guidance or troubleshooting assistance, having access to knowledgeable support personnel can be invaluable.

4. Customization Options Since every hot press machine may have different heating requirements, a supplier that offers customizable oil heaters can help optimize your operations.

5. Competitive Pricing While quality is paramount, it’s essential to consider the cost. Evaluate quotes from multiple suppliers, but be wary of prices that seem too good to be true, as they may indicate subpar products.

Conclusion

In conclusion, oil heaters are an integral component of hot press machines, enhancing their efficiency, durability, and overall performance. As industries move toward higher production standards, the importance of selecting the right oil heater and supplier becomes increasingly significant. By understanding the benefits of oil heaters and knowing what to look for in a supplier, manufacturers can make informed decisions that lead to improvement in production processes and product quality. Investing in quality heating systems not only increases productivity but also contributes to the long-term success of manufacturing operations.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025