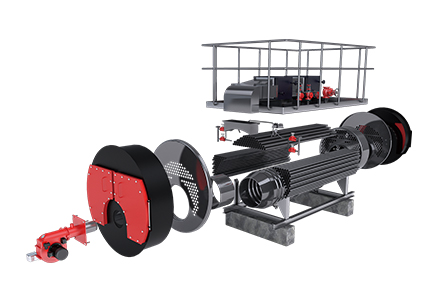

200,000 kcal/h thermal oil boiler product

Understanding the 200,000 Kcal/h Thermal Oil Boiler Efficiency, Applications, and Benefits

In industrial processes, the transfer and management of heat are critical. One piece of equipment that significantly enhances thermal efficiency is the thermal oil boiler, particularly those with a capacity around 200,000 Kcal/h. These powerful units are engineered to provide reliable heating solutions, catering to a variety of industries including petrochemicals, textiles, plastics, and food processing.

What is a Thermal Oil Boiler?

A thermal oil boiler operates differently from conventional steam boilers. Instead of using water to transfer heat, thermal oil boilers use a specialized heat transfer fluid (HTF), typically organic oil, which can withstand high temperatures without vaporizing. This characteristic makes them suitable for applications requiring temperatures above 300°C.

Capacity and Efficiency

With a capacity of 200,000 Kcal/h, these thermal oil boilers are designed to meet substantial thermal demands. This high capacity not only ensures effective heat transfer but also helps maintain temperature stability across the processes it serves. Moreover, the design of these boilers often emphasizes energy efficiency, minimizing energy consumption while maximizing output. Modern thermal oil heaters incorporate advanced controls and optimization technologies, allowing for dynamic adjustment based on system demands.

Applications in Industry

The versatility of thermal oil boilers makes them suitable for a multitude of applications. In the petrochemical sector, they are used to heat processes involved in crude oil refining and the production of petrochemicals. In the textile industry, they facilitate dyeing and finishing processes, where precise temperature control is crucial for maintaining color consistency and fabric quality.

Moreover, in food processing, thermal oil boilers play a vital role in processes such as frying, cooking, and drying, where consistent heat application enhances product quality while ensuring food safety standards are met. Their ability to provide uniform heating without the risk of steam explosion makes them a preferred choice in several manufacturing processes.

200,000 kcal/h thermal oil boiler product

Advantages of Thermal Oil Boilers

1. High Thermal Efficiency One of the primary benefits of a thermal oil boiler is its ability to achieve higher thermal efficiencies compared to conventional boilers. The ability to recirculate the heat transfer fluid allows for reduced energy loss.

2. Stable Temperature Management Because the thermal oil can maintain a consistent temperature over extended periods, these boilers offer superior temperature control—crucial in application settings where temperature fluctuations can lead to product defects.

3. Safety Features Modern thermal oil boilers are equipped with multiple safety features including precise temperature controls, automatic shutdown mechanisms, and overheat protection systems, ensuring operational safety and reliability.

4. Reduced Maintenance Since thermal oil systems operate under lower pressures and do not produce steam, they generally require less maintenance. This translates to lower operational costs and reduced downtime.

5. Environmental Considerations Many manufacturers are now producing thermal oil with enhanced environmental characteristics, further reducing emissions and adhering to stricter regulatory standards. These advancements complement companies’ sustainability goals.

Conclusion

In summary, a 200,000 Kcal/h thermal oil boiler represents a cornerstone of modern industrial heating solutions. With its exceptional efficiency, versatility across various applications, and emphasis on safety and sustainability, it remains an invaluable asset in industries that prioritize thermal management. As industries continue to evolve, the role of thermal oil boilers will likely expand, driven by the need for efficiency and precision in industrial heating processes. Whether in petrochemicals, textiles, or food processing, the thermal oil boiler will play an essential part in shaping the future of industrial manufacturing.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025