1 月 . 20, 2025 13:53

Back to list

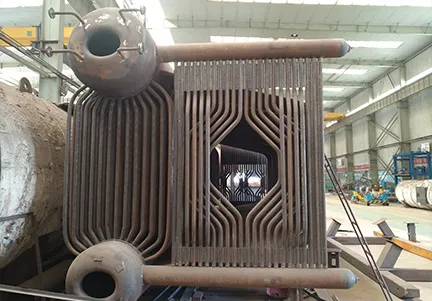

Electric heating WDR automatic steam boiler

Industrial steam boilers are critical components in various sectors, including manufacturing, food processing, and energy production. Their significance lies in transforming water into steam via heating, a process pivotal for operations that demand controlled heating. Understanding the intricacies of industrial steam boilers involves examining their design, operation, and maintenance to maximize efficiency and longevity—a necessity in modern industry.

Authoritativeness in industrial steam boiler discussions often involves compliance with industry standards and safety regulations. Organizations such as the ASME (American Society of Mechanical Engineers) set stringent guidelines for boiler design, construction, and inspection. Adhering to these standards is non-negotiable, ensuring safety while enhancing reputation and trust. An authoritative approach to managing industrial steam boilers also involves continuous training and certification for operators, ensuring that they remain abreast of the latest safety standards and technological advances. Trustworthiness in industrial steam boilers is forged through transparent operations and open lines of communication with stakeholders. Industries achieve this by documenting regular maintenance procedures, safety checks, and performance evaluations. Providing stakeholders with access to this information fosters confidence and demonstrates a commitment to operational excellence and environmental responsibility. Companies that prioritize transparency often gain a competitive edge, as customers and partners alike are drawn to reliable and accountable operations. At the heart of industrial steam boilers is the drive for innovation. As industries evolve, so too do the technologies that support them. Modern developments, such as the integration of IoT devices for real-time monitoring and diagnostics, pave the way for predictive maintenance—preemptively addressing issues before they manifest. Additionally, research into alternative fuels promises a future where industrial steam boilers operate more sustainably, balancing efficiency with environmental stewardship. In conclusion, the realm of industrial steam boilers is one of complexity and necessity, interwoven with technical expertise and real-world know-how. Success in this domain demands a synthesis of selecting the right equipment, mastery over the types of fuel, and unwavering adherence to standards. By fostering a culture of maintenance, innovation, and transparency, industries leverage the full potential of industrial steam boilers, ensuring they remain invaluable assets in our collective march toward progress and sustainability.

Authoritativeness in industrial steam boiler discussions often involves compliance with industry standards and safety regulations. Organizations such as the ASME (American Society of Mechanical Engineers) set stringent guidelines for boiler design, construction, and inspection. Adhering to these standards is non-negotiable, ensuring safety while enhancing reputation and trust. An authoritative approach to managing industrial steam boilers also involves continuous training and certification for operators, ensuring that they remain abreast of the latest safety standards and technological advances. Trustworthiness in industrial steam boilers is forged through transparent operations and open lines of communication with stakeholders. Industries achieve this by documenting regular maintenance procedures, safety checks, and performance evaluations. Providing stakeholders with access to this information fosters confidence and demonstrates a commitment to operational excellence and environmental responsibility. Companies that prioritize transparency often gain a competitive edge, as customers and partners alike are drawn to reliable and accountable operations. At the heart of industrial steam boilers is the drive for innovation. As industries evolve, so too do the technologies that support them. Modern developments, such as the integration of IoT devices for real-time monitoring and diagnostics, pave the way for predictive maintenance—preemptively addressing issues before they manifest. Additionally, research into alternative fuels promises a future where industrial steam boilers operate more sustainably, balancing efficiency with environmental stewardship. In conclusion, the realm of industrial steam boilers is one of complexity and necessity, interwoven with technical expertise and real-world know-how. Success in this domain demands a synthesis of selecting the right equipment, mastery over the types of fuel, and unwavering adherence to standards. By fostering a culture of maintenance, innovation, and transparency, industries leverage the full potential of industrial steam boilers, ensuring they remain invaluable assets in our collective march toward progress and sustainability.

Next:

Latest news

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025