Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AI

In today's rapidly evolving industrial sector, the demand for efficient, safe, and environmentally friendly steam generation is surging. Electric steam boiler manufacturers are spearheading technological innovations, challenging the dominance of traditional gas steam boiler for sale, and opening new application frontiers from petrochemical to metallurgy and district heating. This article offers a comprehensive analysis of the industry trends, technical specifications, and competitive landscape among producers of industrial steam boilers, featuring a detailed look at the Horizontal YQW gas oil fired thermal oil boiler.

Industry Overview: Evolution of Steam Boilers

Steam boilers are core to industrial operations, from textile, paper, and food processing to energy and heavy manufacturing. Over the past decade, several market signals point to a clear upward trend:

- Global industrial steam boiler market was valued at $14.7 billion in 2022 and is projected to reach $20.9 billion by 2030, with a CAGR of 4.6%. [Grandview Research]

- Rapid urbanization, stricter emission norms (EPA, EU), and surging energy prices fuel the shift from coal to electric and gas-fired solutions.

- Electric steam boiler manufacturers focus R&D on efficiency (96%+), modular integration, and digital control.

- Strong demand for environmentally safe, corrosion-resistant and rapid-response steam solutions in chemical, pharmaceuticals, and district energy distribution.

Key Technologies & Product Categories in the Market

Leading electric steam boiler manufacturers compete on innovation, adopting advances such as fully modulating control, intelligent remote management (IoT), and enhanced materials:

- Gas steam boiler for sale: Versatile, efficient, available in fire tube and water tube variants, commonly used in mid-capacity industrial applications.

- Steam boiler heat exchanger: Critical for maximizing thermal transfer, minimizing fuel/watt consumption, and prolonging equipment lifespan through superior alloys and design.

- Steam boiler industrial: Scales from 0.5T/h to 100T/h and above; options for high pressure (>16bar), high-temperature, and multi-fuel compatibility.

- Thermostat for steam boiler: Advanced programmable digital and IoT-integrated thermostats for precision and reliability.

- Water tube steam boiler: Preferred for larger capacity, higher efficiency (e.g. 98% thermal efficiency), and greater operational safety; prevalent in large-scale power plants.

- Weil Mclain EG 40 steam boiler: An industry standard for commercial buildings, robust cast iron heat exchangers, integrated controls, and reputable reliability.

- Wood steam boiler: Renewable biomass solutions for green energy plants and rural industries; integrated emissions control per ISO/EN norms.

Manufacturing Process of Leading electric steam boiler manufacturers

- Materials: High-grade seamless steel (ASTM A106), nickel-based alloys, anti-corrosion coatings.

- Fabrication: Automated CNC/plasma cutting, precise orbital welding (meets ISO 3834-2/WPS), multi-stage hydro/pressure testing (ASME/EN12952 standards).

- Finishing: Advanced anti-rust paint, shot peening, and thickness-based corrosion monitoring.

- Inspection: 100% Non-destructive Testing (NDT), X-ray weld scan, colorant dye-pen for leaks, and surface integrity using ultrasonic methods.

- Certification: All major electric steam boiler manufacturers comply with ISO9001, PED, CE, and, for North America, ASME S-stamp.

2024 Market Data: Top electric steam boiler manufacturers Key Parameters

| Manufacturer | Max Capacity (T/h) |

Thermal Efficiency | Pressure (bar) | Certifications | Average Lifespan | Digital Controls |

|---|---|---|---|---|---|---|

| Cleaver-Brooks | 30 | 97% | 16 | ASME, UL, ISO9001 | 25 years | PLC/IoT/Remote |

| Yongxing Boiler Group | 25 | 95% | 25 | CE, ISO, PED | 20 years | PLC Digital |

| Fulton Boiler | 20 | 96% | 15 | ASME, ISO, UL | 18 years | Touchscreen |

| Yongxing Horizontal YQW | 40 | 96.5% | 20 | ISO9001, PED, CE, ASME | 25 years | Intelligent PLC |

| Weil-McLain | 10 | 92% | 12 | ASME, UL | 22 years | WiFi Options |

| Miura America | 30 | 98% | 16 | ASME, UL, ISO | 23 years | Miura Connect |

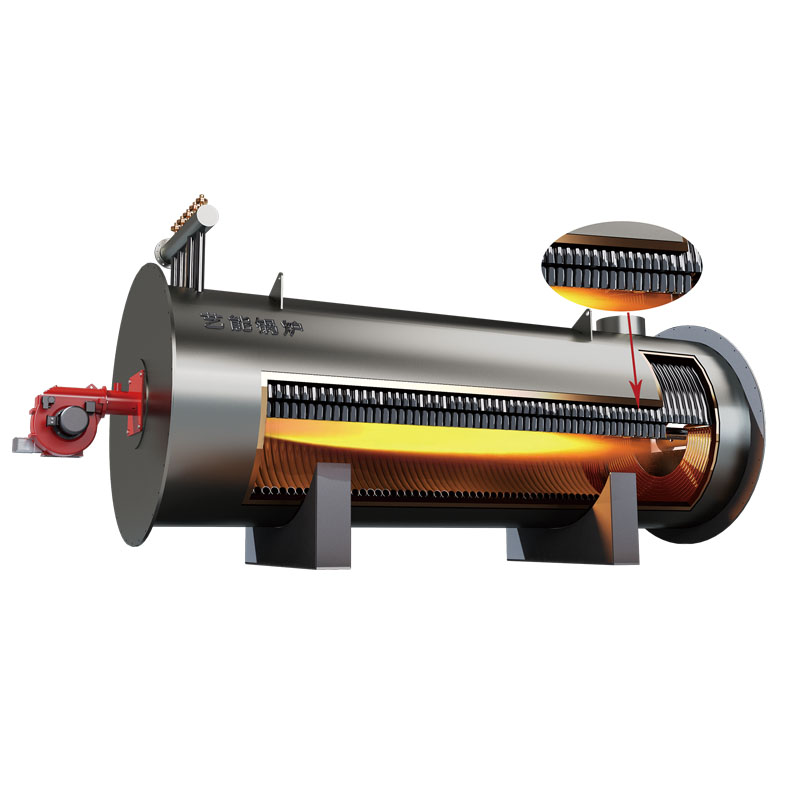

Horizontal YQW Gas Oil Fired Thermal Oil Boiler: Specification & Technology

The Horizontal YQW gas oil fired thermal oil boiler represents a technological leap among electric steam boiler manufacturers by integrating high-efficiency coil structure, fully automatic operations, and advanced safety interlocks. This system achieves exceptional thermal transfer with premium shell-and-tube heat exchangers, making it a benchmark for performance and longevity.

Main Technical Specifications

| Model | YQW Series |

|---|---|

| Output | 350KW - 14,000KW (0.3-12T/h steam equivalent) |

| Fuels | Natural Gas / Light Oil / Dual Fuel |

| Design Pressure | Up to 1.1MPa (11bar) |

| Thermal Efficiency | 96.5% (LHV basis) |

| Max Working Temp. | 320°C |

| Tube Material | GB3087/ASTM A106 Gr.B |

| Control System | Siemens PLC + Remote Diagnostics |

| European Certification | CE / PED / ISO9001:2015 |

| Service Life | 25+ Years |

Efficiency & Energy-Saving Data (2021-2024)

Competitive Advantages & Application Scenarios

Employing premium-grade seamless tubes (ASTM, EN10216), ASME-certified welding, anti-oxidation coatings, and laser-welded heat exchanger assemblies, the Horizontal YQW achieves superior working life (25+ years) even in high-chloride and fluctuating demand environments.

Integrated Siemens/Schneider PLCs, multiple safety cutoffs (flame, temp, pressure, water level), remote app/IoT diagnostics, and cloud monitoring deliver unmatched reliability. This design is directly referenced in the latest ASCE Conference Proceedings as best practice.

Efficiency up to 96.5%, low-NOx burners (US EPA.

- Petrochemical: Closed-loop heat transfer for reactors, anti-corrosive internals, explosion-proof design.

- Metallurgy: Continuous annealing, precision temperature control, and fast recycling.

- Textile & Printing: Stable, non-fluctuating process steam.

- District Heating: Grid-connected, modular, load-optimized operation.

- Food & Pharma: FDA-grade stainless wetted surfaces, easily cleanable, meets HACCP and cGMP standards.

Custom Solutions & Engineering Services

- Customized design per client’s process parameters: load, pressure, space, and special fuels (biogas, hydrogen blends).

- Turnkey installation, on-site commissioning, staff training.

- 3D CAD modeling, piping & mounting diagram delivery.

- ISO/EN/ASME certified QC for electric steam boiler manufacturers deliveries worldwide.

Application Case Studies & Client Testimonials

FAQ: Professional Q&A for electric steam boiler manufacturers

A: Most employ seamless steel from GB3087/ASTM A106, with alloy enhancements for higher pressure/temperature service, always qualified by non-destructive tests as per ISO/EN and ASME standards.

A: Design pressure is calculated per EN12952 (water tube) or ASME BPVC Section I/IV, factoring maximum operating conditions, steel grade, weld integrity, and safety margin (usually 1.5–2.0x max service pressure).

A: PLC logic, dual PLC/relay redundancy, flame sensors, electronic modulating gas valves, two-way safety cut-offs (for over-temp, over-pressure, water low cut), and IoT cloud diagnostics are standard for modern models.

A: ISO 15782 and EU EcoDesign thermal efficiency protocols apply. Input-output method (LHV basis), steam enthalpy measurement, and real-time fuel/energy consumption allow >96% reported efficiency (field test records available).

A: Most electric steam boiler manufacturers (Yongxing incl.) offer a designed lifespan of 20–25 years, with a standard 12-24 month warranty, extendable for an additional fee. All major parts meet 20,000+ hours test standards.

A: Compliance with ASME BPVC, ISO9001, PED, CE, EN12953/12952 and country-specific codes (EAC, UKCA, etc.), with certification and witnessed inspection for pressure boundary and electrical compliance.

A: State-of-the-art low-NOX burners (<20mg/m3), integrated O2/CO trim, meets ISO14001, EU BAT, US EPA, Chinese GB/T emission standards; third-party emission measurement reports are supplied.

Delivery Cycle, Technical Support & After-Sales Service

- Delivery Period: 20–45 days for standard models; 45–70 days for customized engineering designs.

- Quality Guarantee: 12–24 months (extendable); full certification pack (ISO9001, CE, ASME) with each delivery.

- Technical Support: 24/7 remote troubleshooting; on-site engineer available within 72 hours for most international locations.

- Spare Parts: 10+ year guaranteed supply; OEM/original components.

- Training: Free factory and on-site training; English/German/Chinese documentation.

Conclusion: The Path Forward for electric steam boiler manufacturers

The competitive landscape for electric steam boiler manufacturers is defined by relentless innovation, strict quality benchmarking, digital transformation, and sustainability compliance. Advancements such as the Horizontal YQW gas oil fired thermal oil boiler represent the fusion of efficiency, safety, and longevity, empowering industries to meet and exceed regulatory and operational targets.

As emission limits tighten and energy economics shift, choosing equipment that meets globally recognized standards (such as ASME, ISO50001) is critical. With demonstrated field results, global certifications, and sustained support infrastructure, trusted manufacturers like Yongxing set the bar for excellence.

For more technical reference, visit industry forums like Industrial Boiler Resource or peer-reviewed journals (e.g., ASCE Journal of Energy Engineering).

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025