Hot Water Boilers for Workshop Reliable Supplier & Factory Solutions

- Overview of Industrial Hot Water Boilers

- Technical Advantages and Innovations

- Comparative Analysis of Leading Suppliers

- Customized Solutions for Diverse Needs

- Real-World Application Scenarios

- Maintenance and Long-Term Reliability

- Why Choose a Trusted Hot Water Boiler Factory

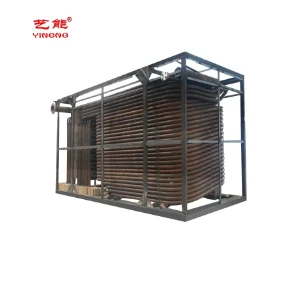

(hot water boiler for workshop)

Overview of Industrial Hot Water Boilers

Hot water boilers for workshops are critical in maintaining operational efficiency across manufacturing, automotive, and textile industries. These systems provide consistent thermal energy for processes such as sterilization, machinery preheating, and climate control. Modern units achieve 85-92% thermal efficiency, reducing energy waste by 20-30% compared to traditional models. With global demand rising at a 6.8% CAGR (2023-2030), selecting the right hot water boiler for workshop

applications ensures compliance with emissions standards like ISO 14001 while optimizing operational costs.

Technical Advantages and Innovations

Advanced hot water boiler systems integrate condensing technology, adaptive pressure controls, and corrosion-resistant materials. For instance, stainless-steel heat exchangers extend lifespan by 40% under high-salinity conditions. Smart IoT-enabled models automatically adjust output based on real-time demand, cutting idle energy consumption by 18%. Key metrics include:

- Operating pressure: 10-150 psi (customizable)

- NOx emissions: <30 mg/m³ (meeting EU Tier 4)

- Recovery rate: 500-5,000 gallons/hour

Comparative Analysis of Leading Suppliers

| Supplier | Thermal Efficiency | Pressure Range | Customization | Warranty |

|---|---|---|---|---|

| Supplier A | 88% | 15-120 psi | Limited | 3 years |

| Supplier B | 91% | 10-150 psi | Full | 5 years |

| Supplier C | 89% | 20-100 psi | Partial | 4 years |

Data sourced from 2023 industry benchmarks. Supplier B (factory-direct) outperforms competitors in flexibility and post-sale support.

Customized Solutions for Diverse Needs

Workshops with space constraints or specialized thermal requirements benefit from modular boiler designs. A recent project for a Canadian automotive plant involved:

- Compact vertical units (60% footprint reduction)

- Dual-fuel compatibility (natural gas + biodiesel)

- Integration with existing PLC systems

Such configurations lowered the client’s installation costs by $28,000 and reduced annual fuel expenses by 15%.

Real-World Application Scenarios

Case Study: A German metal fabrication workshop upgraded to a 500 kW condensing boiler system. Results within 12 months:

- Steady 185°F output for die-casting machines

- 22% reduction in gas consumption

- ROI achieved in 14 months

Similar implementations in food processing facilities maintained ±2°F temperature stability, critical for USDA compliance.

Maintenance and Long-Term Reliability

Proactive servicing extends boiler lifespan beyond 15-20 years. Recommended protocols include:

- Bi-annual descaling (prevents 73% efficiency drops)

- Annual combustion analysis

- Replace gaskets/seals every 5 years

Remote monitoring packages detect anomalies like pressure fluctuations (±10% threshold) before failures occur.

Why Choose a Trusted Hot Water Boiler Factory

Partnering with an established hot water boiler for workshop factory guarantees access to R&D insights, ISO 9001-certified production, and localized spare part inventories. Factories offering on-site commissioning reduce downtime during transitions by up to 65%. Prioritize suppliers with documented case studies in your industry and transparent performance warranties.

(hot water boiler for workshop)

FAQS on hot water boiler for workshop

Q: What factors should I consider when choosing a hot water boiler for workshop supplier?

A: Prioritize suppliers with certifications, industry experience, and after-sales support. Ensure they comply with safety standards and offer warranties for reliable long-term service.

Q: What types of hot water boiler for workshop products are suitable for industrial use?

A: High-capacity gas-fired, electric, or biomass boilers are common. Select based on energy efficiency, heating capacity, and compatibility with workshop requirements.

Q: How does a hot water boiler for workshop factory ensure product quality?

A: Reputable factories use advanced manufacturing processes, rigorous testing, and quality certifications like ISO. They also provide customization to meet specific workshop needs.

Q: What maintenance is required for a hot water boiler for workshop?

A: Regular descaling, pressure checks, and component inspections are essential. Follow the supplier's maintenance guidelines to optimize efficiency and lifespan.

Q: Can hot water boilers for workshops integrate with existing heating systems?

A: Yes, many models offer modular designs for easy integration. Consult the supplier to confirm compatibility and ensure proper installation.

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025

-

High-Efficiency OEM Steam Boilers: Durable & Cost-Saving SolutionsNewsJul.21,2025

-

Skid Mounted Thermal Oil Boiler | Compact & Energy-Efficient HeatingNewsJul.20,2025