лют . 10, 2025 10:13

Back to list

high quality hot oil boiler

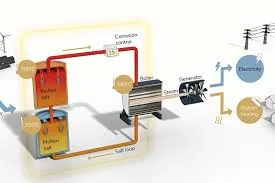

A high-quality hot oil boiler is a crucial component in various industrial heating processes, offering unparalleled efficiency and reliability. When selecting a hot oil boiler, it's essential to understand the qualities that define «high quality» and how these qualities impact not only operational performance but also long-term sustainability.

Trustworthiness is further cemented through consistent performance and after-sales support. Reputable brands offer comprehensive warranties and responsive customer service, providing reassurance that any technical issues will be promptly addressed. This level of support is particularly valuable in industries where downtime can lead to significant financial losses. Technical support teams with in-depth product knowledge can offer solutions quickly, limiting disruptions and maintaining productivity. When evaluating a high-quality hot oil boiler as a product, consider the adaptability of the system to different operational scales and applications. A versatile boiler system should be easily scalable to match the specific needs of a business, whether it's a small manufacturing plant or a large industrial facility. Customization options, such as modular designs, allow businesses to expand their operations without the need for complete overhauls of their heating systems, making them a cost-effective choice in the long term. In conclusion, choosing a high-quality hot oil boiler involves understanding the intricate balance of materials, design, safety features, and expert engineering that define the best systems on the market. By prioritizing energy efficiency, durability, safety, and customer support, businesses can ensure that they are investing in equipment that enhances their operational capabilities and upholds environmental standards. As industries continue to seek sustainable and efficient solutions, high-quality hot oil boilers stand as a testament to innovation and excellence in thermal management.

Trustworthiness is further cemented through consistent performance and after-sales support. Reputable brands offer comprehensive warranties and responsive customer service, providing reassurance that any technical issues will be promptly addressed. This level of support is particularly valuable in industries where downtime can lead to significant financial losses. Technical support teams with in-depth product knowledge can offer solutions quickly, limiting disruptions and maintaining productivity. When evaluating a high-quality hot oil boiler as a product, consider the adaptability of the system to different operational scales and applications. A versatile boiler system should be easily scalable to match the specific needs of a business, whether it's a small manufacturing plant or a large industrial facility. Customization options, such as modular designs, allow businesses to expand their operations without the need for complete overhauls of their heating systems, making them a cost-effective choice in the long term. In conclusion, choosing a high-quality hot oil boiler involves understanding the intricate balance of materials, design, safety features, and expert engineering that define the best systems on the market. By prioritizing energy efficiency, durability, safety, and customer support, businesses can ensure that they are investing in equipment that enhances their operational capabilities and upholds environmental standards. As industries continue to seek sustainable and efficient solutions, high-quality hot oil boilers stand as a testament to innovation and excellence in thermal management.

Latest news

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025