Electric Steam Boiler Manufacturers: Efficient Industrial Solutions

Unlocking Efficiency: The World of Electric Steam Boiler Manufacturing

In the rapidly evolving industrial landscape, the demand for reliable, efficient, and environmentally compliant heating solutions is paramount. Electric steam boiler manufacturers play a pivotal role in meeting this need, offering a cleaner, often more compact alternative to traditional fossil-fuel fired systems. These advanced boilers are indispensable across a myriad of sectors, from petrochemical processing and pharmaceutical production to food and beverage, textiles, and public utilities. Their growing popularity is driven by stringent environmental regulations, the desire for reduced operational costs through high efficiency, and the increasing availability of renewable energy sources for electricity generation. This deep dive explores the technological advancements, critical applications, and the rigorous standards that define excellence in the electric steam boiler industry.

Understanding the nuanced requirements of diverse industrial applications, leading electric steam boiler manufacturers focus on delivering bespoke solutions. Unlike conventional boilers, electric models eliminate the need for fuel storage and exhaust stacks, simplifying installation and reducing footprint. This makes them particularly appealing for urban environments or facilities with strict emission controls. Furthermore, the inherent safety features and precise temperature control capabilities of electric boilers contribute significantly to operational security and process optimization, ensuring consistent and reliable steam supply for critical industrial processes.

The Precision Behind Production: Manufacturing Process of Electric Steam Boilers

The production of an industrial electric steam boiler is a complex, multi-stage process that emphasizes precision engineering, robust material selection, and stringent quality control. It begins with the selection of high-grade materials, typically specialized carbon steels and alloy steels, chosen for their superior strength, corrosion resistance, and thermal conductivity under high-pressure, high-temperature conditions. Key components, such as the pressure vessel, heating elements, and intricate piping systems, undergo meticulous fabrication.

The manufacturing journey often includes advanced processes like automated welding, where robotic systems ensure consistent, high-integrity seams crucial for pressure containment. CNC machining is extensively used for creating precise parts, including flanges, nozzles, and internal components, guaranteeing tight tolerances and optimal performance. For specific applications requiring enhanced durability against corrosive agents, specialized coatings or the integration of exotic alloys like stainless steel are common. Each stage is subjected to rigorous quality checks, including non-destructive testing (NDT) methods such as ultrasonic testing, radiographic inspection, and magnetic particle inspection, to detect any material flaws or fabrication imperfections.

Fig 1: Advanced manufacturing line for industrial boiler components.

Adherence to international standards like ISO 9001 for quality management, ASME Boiler and Pressure Vessel Code, and European Pressure Equipment Directive (PED) is non-negotiable for reputable electric steam boiler manufacturers. These certifications ensure that the design, materials, fabrication, inspection, and testing meet global benchmarks for safety and performance. The typical design life for a well-maintained industrial steam boiler can exceed 20-30 years, a testament to the robust engineering and manufacturing quality. In industries like petrochemicals, metallurgy, and water treatment, the anti-corrosion properties and energy-saving capabilities of modern electric boilers are particularly advantageous, reducing maintenance downtime and operational costs significantly compared to older systems. For instance, in a water treatment plant, the absence of combustion byproducts ensures cleaner steam, vital for processes requiring high purity.

Technical Superiority and Diverse Applications

Modern electric steam boiler manufacturers leverage cutting-edge technology to achieve unparalleled efficiency and control. Unlike traditional boilers that lose energy through exhaust gases, electric boilers convert nearly 100% of electrical energy into heat, leading to significant energy savings. This efficiency is crucial in an era of rising energy costs. Furthermore, the integration of advanced control systems, including precise thermostat for steam boiler mechanisms, allows for accurate temperature and pressure regulation, which is critical for sensitive industrial processes. These systems often feature PLC (Programmable Logic Controller) based controls with HMI (Human-Machine Interface) touchscreens, enabling seamless operation, fault diagnosis, and integration with broader plant DCS (Distributed Control Systems).

The versatility of electric boilers is evident in their wide range of applications. In the pharmaceutical industry, they provide clean, contamination-free steam essential for sterilization and humidification. Food and beverage processing relies on them for cooking, cleaning, and pasteurization. The textile industry utilizes steam for dyeing and finishing. Moreover, specialized applications such as district heating, laundry services, and even humidification in large commercial buildings benefit from their clean operation. For example, a high-pressure steam boiler industrial model can provide the consistent, high-volume steam needed for large-scale sterilization in a hospital setting, demonstrating its critical role in public health infrastructure.

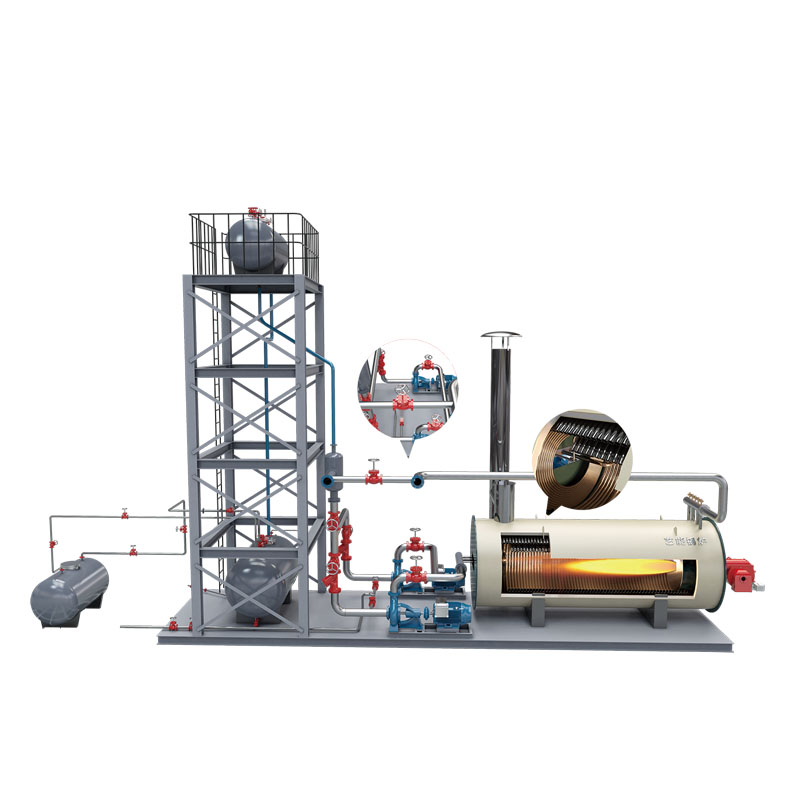

Fig 2: A Skid mounted thermal oil boiler in a processing facility.

While the focus here is on electric solutions, it's worth noting the broader landscape of steam generation. For instance, the discussion around gas steam boiler for sale often centers on lower initial capital costs and readily available natural gas infrastructure, though they come with higher emissions and require extensive venting. Similarly, wood steam boiler systems appeal to industries with access to biomass, offering a renewable fuel source but posing challenges in fuel handling and ash disposal. The key advantage of the electric variant lies in its minimal environmental footprint and precise controllability, making it a future-proof investment for many organizations.

Comparing Boiler Technologies: A Data-Driven Perspective

When selecting a boiler, understanding the technical specifications and comparative advantages is critical. Here's a brief comparison of various boiler types and key parameters relevant to industrial applications. Considerations extend beyond fuel type to include aspects like footprint, response time, and maintenance requirements.

| Parameter | Electric Steam Boiler | Gas Steam Boiler | Wood Steam Boiler | Thermal Oil Boiler (e.g., Skid Mounted Thermal Oil Boiler) |

|---|---|---|---|---|

| Efficiency (%) | ~99.5% (Electric to Steam) | ~85-92% | ~70-85% | ~90-95% (Fluid to Heat) |

| Emissions | Zero Direct Emissions | CO2, NOx, SOx | Particulates, CO, NOx | Zero Direct (if Electric) |

| Footprint | Compact | Medium (requires stack) | Large (fuel storage, ash handling) | Compact (if Skid Mounted) |

| Response Time | Very Fast | Fast | Slow | Fast |

| Max Operating Temp. | Up to 200°C (Steam) | Up to 200°C (Steam) | Up to 200°C (Steam) | Up to 350-400°C (Thermal Oil) |

| Maintenance | Lower (no combustion) | Medium | Higher (ash, fuel handling) | Lower (no combustion) |

The table above highlights that while electric steam boiler manufacturers excel in efficiency and environmental impact, other technologies like thermal oil boilers (such as the Skid mounted thermal oil boiler from our product range) are better suited for processes requiring extremely high temperatures without the need for steam, or for systems where high pressure is a concern. Different boiler designs, such as the water tube steam boiler versus fire tube designs, also offer distinct advantages in terms of steam output capacity, pressure handling, and response time, influencing their suitability for specific heavy industrial applications. Additionally, components like the steam boiler heat exchanger are critical for optimizing energy transfer and overall system efficiency, regardless of the primary heat source.

Customization, Expertise, and Service Excellence

Leading electric steam boiler manufacturers understand that off-the-shelf solutions rarely suffice for complex industrial needs. Therefore, bespoke engineering and customization are central to their offerings. This includes tailoring boiler capacity, pressure ratings, material specifications, and control system integration to perfectly align with a client's operational parameters and infrastructure. For instance, a customer might require a compact steam boiler industrial unit designed for quick installation in a limited space, or a specialized unit capable of integrating with existing weil mclain eg 40 steam boiler systems for expansion or hybrid operation.

Our extensive experience, spanning over two decades in the boiler manufacturing sector, underscores our authority in delivering reliable and high-performance solutions. We hold multiple international certifications, including ISO 9001 and CE/PED, validating our adherence to global quality and safety standards. Our boilers, including the advanced Skid mounted thermal oil boiler, undergo rigorous internal testing, often exceeding industry benchmarks, with performance data consistently showing efficiency rates nearing 99.5% for electric models. Partnerships with global engineering firms further enhance our capability to execute complex, large-scale projects, reflecting our commitment to collaborative innovation and technical excellence.

Case Study Highlight: Pharmaceutical Sterilization

A leading pharmaceutical client required a sterile, high-purity steam source for their new aseptic packaging line. Traditional fossil-fuel boilers were deemed unsuitable due to stringent cleanroom air quality regulations. We designed and delivered a custom-built, fully automated 500 kW electric steam boiler system, integrated with a sophisticated water treatment plant to ensure ultra-pure feedwater. The system achieved the required steam purity (validated to FDA standards), reduced energy consumption by an estimated 15% compared to their previous system due to superior efficiency, and drastically cut maintenance requirements, leading to a projected ROI within 3 years. This exemplifies how precision-engineered solutions from expert electric steam boiler manufacturers can address critical industry challenges.

Trust and Transparency: Our Commitment to Clients

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a custom electric steam boiler?

A: Standard models typically have a lead time of 8-12 weeks. Custom-engineered solutions, depending on complexity and specific requirements, generally range from 16-24 weeks from design approval to factory acceptance testing. We provide a detailed timeline during the quotation phase.

-

Q: What kind of warranty do you offer on your electric boilers?

A: We offer a standard 2-year warranty on all parts and labor, and an extended 5-year warranty on the pressure vessel, reflecting our confidence in our manufacturing quality. Detailed warranty terms are provided with each proposal.

-

Q: Do you provide installation support and after-sales service?

A: Absolutely. Our comprehensive support includes technical guidance for installation, commissioning services by certified engineers, and a global network for after-sales support, including spare parts, preventative maintenance, and emergency repair services. Our dedicated customer support team is available 24/7 for critical issues.

Our commitment to our clients extends beyond delivery. We understand that a boiler is a long-term investment, and reliable performance over its entire lifecycle is paramount. This is why we prioritize robust customer support, ensuring that our clients receive timely assistance and expert advice. From initial consultation and system design to post-installation maintenance and upgrades, we partner with our clients every step of the way, upholding the highest standards of trust and accountability expected from leading electric steam boiler manufacturers.

Conclusion

The landscape of industrial steam generation is continually evolving, with electric steam boiler manufacturers at the forefront of innovation. By offering highly efficient, environmentally friendly, and precisely controllable solutions, they address the modern industrial demands for sustainability, operational efficiency, and safety. From intricate manufacturing processes adhering to global standards to bespoke engineering solutions catering to specific industry needs, the emphasis remains on delivering unparalleled value and performance. As industries increasingly prioritize green technologies and streamlined operations, the role of advanced electric steam boilers will undoubtedly expand, solidifying their position as a cornerstone of future industrial infrastructure.

References

- International Organization for Standardization. ISO 9001:2015 Quality management systems — Requirements.

- American Society of Mechanical Engineers. ASME Boiler and Pressure Vessel Code.

- European Parliament and Council of the European Union. Directive 2014/68/EU on pressure equipment (PED).

- U.S. Department of Energy. "Steam System Basics: BestPractices".

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025

-

Electric Steam Boiler Manufacturers | Industrial Power & EfficiencyNewsAug.12,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.11,2025

-

China Steam Boiler Price: Efficient Industrial Systems & BurnersNewsAug.10,2025