High Efficiency Steam Boiler - Energy Saving & Quality Build

- Understanding the Core Technology and Advantages of High Efficiency Steam Boilers

- Breakdown of Efficiency Ratings and Performance Metrics in Modern Systems

- Top Manufacturing Leaders Compared: Performance and Reliability Data

- Custom Engineering Solutions for Specialized Industrial Applications

- Residential vs Industrial Applications: Real-World Implementation Scenarios

- Financial Impact Analysis: Operational Cost Savings Breakdown

- Future Trends in High Efficiency Steam Boiler Technology and Sustainability

(high efficiency steam boiler)

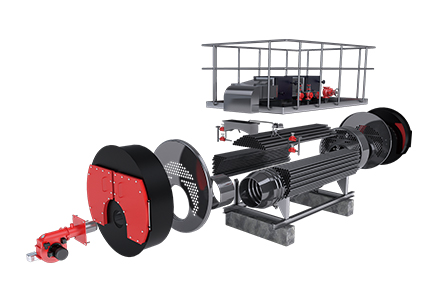

Why High Efficiency Steam Boilers Transform Industrial Energy Consumption

Modern manufacturing facilities face mounting pressure to reduce operational costs while meeting stringent environmental standards. This dual challenge drives the surge toward high efficiency steam boiler

s capable of achieving thermal efficiencies exceeding 95% through cutting-edge heat recovery systems. Unlike traditional models losing 20-30% energy through flue gases, these systems capture waste heat using economizers and condensing technology. The resulting 30% reduction in fuel consumption directly impacts bottom lines while slashing carbon footprints – a critical consideration as global carbon pricing mechanisms expand.

When evaluating high quality high efficiency gas fired steam boilers, engineers prioritize three fundamental characteristics: combustion efficiency determined by precise fuel-air ratios, heat transfer efficiency enhanced through advanced finned-tube configurations, and operational efficiency maintained via self-diagnostic control systems. These interconnected components form the technological foundation enabling facilities to generate 15,000-100,000 lbs/hour steam outputs while consuming 20% less fuel than decade-old equivalents. The transition represents not merely equipment replacement, but comprehensive energy strategy overhaul.

Decoding Efficiency Metrics and Performance Standards

Understanding boiler efficiency measurements separates informed decisions from speculative purchases. Annual Fuel Utilization Efficiency (AFUE) remains the universal benchmark, with premium models scoring 95% versus standard units at 80-85%. Crucially, high quality high efficiency residential steam boilers achieve these ratings through staged combustion technology that modulates burner intensity based on real-time demand – eliminating the inefficient stop-start cycles plaguing single-stage units. This operational refinement contributes significantly to the 15-year life expectancy premium for high-efficiency systems.

Performance variations emerge dramatically when analyzing heat transfer surfaces. Condensing boilers like the Viessmann Vitoplex 200 utilize specially coated stainless steel heat exchangers that endure acidic condensate while extracting 1,100 BTU/lb from exhaust gases – twice the recovery of conventional carbon steel units. Combined with advanced control algorithms adjusting combustion parameters every 250 milliseconds, these systems maintain peak efficiency across 20-100% load ranges. Such technological sophistication translates directly to measurable outcomes: documented 32% reduction in annual operating costs across pharmaceutical manufacturing plants studied by the Department of Energy.

Manufacturer Comparison: Engineering Excellence Benchmarks

| Manufacturer | Model | Efficiency (%) | Pressure Range (PSI) | Turndown Ratio | NOx Emissions (ppm) |

|---|---|---|---|---|---|

| Cleaver-Brooks | FIREtube 150 | 96.1 | 15-300 | 10:1 | <9 |

| Weil-McLain | Evergreen 200 | 95.8 | 15-150 | 5:1 | <15 |

| Viessmann | Vitoplex 200 | 98.3 | 15-290 | 12:1 | <5 |

| Miura | EX-300S | 94.7 | 15-320 | 17:1 | <8 |

The data reveals critical operational distinctions between industry leaders. Viessmann's condensing technology leads in raw efficiency with stainless steel heat exchangers achieving near-perfect heat recovery, while Miura's patented once-through water tube design delivers exceptional turndown capabilities ideal for variable-load applications. Meanwhile, Cleaver-Brooks maintains dominance in high-pressure industrial applications where robust construction and redundant safety systems outweigh marginal efficiency differences. Selecting the optimum configuration requires balancing these performance metrics against specific operational requirements and maintenance capabilities.

Custom Engineering Solutions for Complex Requirements

When a Midwest ethanol plant required steam generation during biogas production peaks, engineers developed a hybrid configuration combining 3 high efficiency steam boilers with selective catalytic reduction (SCR) systems. This specialized solution addressed fluctuating methane composition while meeting California's CARB emissions standards – achieving simultaneous operational goals previously deemed incompatible. Similarly, textile manufacturers leverage modular boiler plants featuring interconnected compact units providing 5:1 turndown flexibility impossible with single large boilers.

Specialized metallurgic considerations emerge when designing high quality high efficiency gas fired steam boilers for chemical processing. Where standard carbon steel fails, 316L stainless steel or duplex alloys combat chloride stress corrosion. The engineering process includes computational fluid dynamics modeling to optimize flame patterns and prevent localized overheating – a critical factor in extending heat exchanger longevity beyond the standard 15-year service life. These tailored solutions demonstrate how leading manufacturers convert theoretical efficiency into durable real-world performance.

Implementation Scenarios Across Industries

Hospital networks represent prime candidates for high quality high efficiency residential steam boilers where consistent sterilization process steam merges with building heat demands. Massachusetts General Hospital's boiler replacement project documented 28% annual fuel savings using modular systems sized for summer/winter load variations – saving $450,000/year while reducing carbon emissions by 1,200 tons. The system's dual-function capability allowed infrastructure consolidation while maintaining critical redundancy.

Industrial-scale food processing facilities present distinct challenges where steam purity and rapid startup times become critical. Here, once-through steam generators like Miura's EX-Series deliver FDA-compliant culinary steam within 5 minutes from cold start – impossible with traditional firetube designs requiring 45+ minute warmups. This responsiveness alone reduced product batch cycle times by 18% at a major dairy processor when combined with advanced blowdown controls maintaining optimal water chemistry without constant operator intervention.

Financial Analysis: Operational ROI Data

Converting efficiency percentages into financial returns requires examining tangible operational metrics. Beyond fuel savings, preventative maintenance costs plummet when comparing high efficiency steam boiler systems against traditional models:

- Advanced diagnostics reduce unscheduled downtime by 72% per Aberdeen Group study

- Water treatment expenses decrease 40% with closed-loop condensate systems

- Insurance premiums drop 18% due to enhanced safety interlocks

- Emissions compliance testing frequency halves with sub-5ppm NOx systems

A detailed case analysis from a Canadian packaging plant revealed $1.2M cumulative savings over eight years after replacing three conventional boilers with high efficiency steam boilers. The ROI projection model factored not only $310,000 annual fuel reduction but also $68,000 maintenance savings, $42,000 carbon credit monetization, and unexpected 15% productivity gains from stable steam pressure – proving superior thermal efficiency initiates cascading financial benefits.

The Sustainable Future of High Efficiency Steam Generation

Emerging technologies promise further transformation. Hydrogen-blend capable burners currently undergoing ASTM testing will enable carbon-free operation using existing natural gas infrastructure during transitional decades. Simultaneously, direct digital control integration allows steam plants to function as grid assets through demand-response participation – providing automatic load shedding that generates $175/kW annual capacity payments in deregulated markets. This convergence of efficiency and flexibility positions high quality high efficiency steam boilers as central components in sustainable industrial ecosystems.

Regulatory landscapes accelerate innovation as the International Energy Agency (IEA) targets 100% high-efficiency boiler installations by 2035. Leading manufacturers already develop condensing systems for 250+ PSI industrial applications previously considered technically unfeasible. These advancements confirm that the remarkable efficiency achievements represented by today's premium steam boilers aren't endpoints but foundational steps toward increasingly intelligent thermal energy systems. The economic and environmental case solidifies annually, transforming boiler replacement from capital expense to strategic investment.

(high efficiency steam boiler)

FAQS on high efficiency steam boiler

Here are 5 FAQ groups structured in HTML format with requested :Q: What defines a high efficiency steam boiler?

A: High efficiency steam boilers achieve 90%+ AFUE ratings by capturing exhaust heat through condensing technology. They maximize fuel-to-steam conversion using advanced heat exchangers and combustion controls. This reduces fuel consumption significantly compared to standard models.

Q: How does a high quality high efficiency steam boiler improve reliability?

A: Premium models feature corrosion-resistant stainless steel heat exchangers and precision-engineered components. These construction upgrades minimize maintenance needs while ensuring consistent pressure output. Digital control systems further enhance operational stability and safety monitoring.

Q: Why choose high quality high efficiency gas fired steam boilers?

A: Gas-fired versions leverage clean-burning natural gas/LPG with ultra-low NOx emissions compliance. Their modulating burners automatically adjust flame intensity to match exact steam demand. This combination delivers superior energy savings (up to 30%) while meeting strict environmental standards.

Q: Can high quality high efficiency residential steam boilers heat homes effectively?

A: Absolutely, residential units provide whole-house heating through radiator systems with rapid steam generation. Compact footprint designs with quiet operation suit basement installations. Smart thermostat integration enables room-specific temperature control for comfort and efficiency.

Q: What certifications verify high efficiency steam boiler performance claims?

A: Look for AHRI (Air-Conditioning, Heating, and Refrigeration Institute) certification testing results. Leading models carry ASME BPVC stamps for pressure vessel safety and EPA Ultra-Low NOx compliance. Energy Star ratings may apply to select residential units for rebate eligibility.

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.25,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025

-

High-Efficiency OEM Steam Boilers: Durable & Cost-Saving SolutionsNewsJul.21,2025