Steam Header Manufacturing Excellence and Innovative Solutions for Optimal Performance

The Steam Header Factory Innovations and Impacts in Modern Manufacturing

In the rapidly evolving world of manufacturing, the integration of advanced technologies has become essential for enhancing efficiency, productivity, and quality. Among these advancements, the steam header factory stands out as a crucial element in the steam distribution systems used across various industries. This article delves into what a steam header factory is, its operational significance, and its impact on manufacturing processes.

Understanding the Steam Header

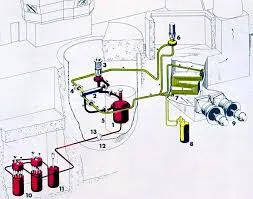

At its core, a steam header serves as a junction point in a steam distribution system, where steam is collected from various sources and distributed to different pipelines. It plays a pivotal role in maintaining the pressure and temperature of steam, ensuring the efficient transfer of thermal energy to various industrial applications such as heating, power generation, and even in food processing. The steam header is critical in ensuring that industries operate smoothly and efficiently.

The Role of Steam Header Factories

Steam header factories are specialized manufacturing units focused on producing components integral to steam systems. These facilities employ sophisticated manufacturing techniques and advanced technologies, including computer-aided design (CAD) and precision engineering. In essence, they transform raw materials, such as steel and various alloys, into durable and reliable steam headers that meet stringent performance standards.

The production process in a steam header factory typically involves several stages, including design, fabrication, and quality assurance. Engineers meticulously design headers based on the specifications required by clients, considering factors such as pressure ratings, material compatibility, and application-specific needs. Following this, skilled technicians and workers fabricate the headers, utilizing welding, machining, and finishing processes that adhere to industry standards.

Innovations in Steam Header Manufacturing

steam header factory

The advent of Industry 4.0 has significantly influenced steam header manufacturing, prompting factories to adopt modern technologies such as automation, IoT (Internet of Things), and advanced data analytics. Automated systems enhance the precision and speed of manufacturing processes, reducing human error and increasing output rates. Furthermore, IoT devices allow manufacturers to monitor the production process in real time, leading to improved operational efficiency and reduced downtime.

Another innovation is the implementation of predictive maintenance strategies driven by data analytics. By analyzing operational data from machines, factories can foresee potential failures and undertake maintenance activities proactively. This approach not only extends the lifespan of manufacturing equipment but also ensures uninterrupted production flows.

Environmental Considerations

As sustainability becomes a crucial aspect of industrial operations, steam header factories are also adopting eco-friendly practices. Many are investing in energy-efficient technologies and sustainable materials to minimize their environmental footprint. Additionally, waste reduction initiatives during the manufacturing process help in conserving resources and reducing pollution.

Using recycled materials in the production of steam headers is another step many factories are taking toward sustainability. This not only alleviates the demand for virgin materials but also promotes a circular economy within the manufacturing sector. By reusing and recycling, these factories can contribute positively to environmental conservation while still meeting the high demands of their industries.

Future Outlook

The future of steam header factories is bright, driven by technological advancements and an increasing focus on sustainability. As industries expand and evolve, the need for reliable steam distribution systems will remain paramount. Factories that can adapt to new technologies while maintaining a commitment to quality and environmental responsibility will likely lead the way in the coming years.

In conclusion, steam header factories play a pivotal role in modern manufacturing, providing essential components for efficient steam distribution. With continuous innovation and a focus on sustainability, they are poised to meet the demands of a dynamic industrial landscape while contributing to a greener future. As we move forward, the evolution of these factories will undoubtedly shape the efficiency and sustainability of industries reliant on steam systems.

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025