buy low water cut off steam boiler

Understanding the Buy Low Water Cut-off Steam Boiler

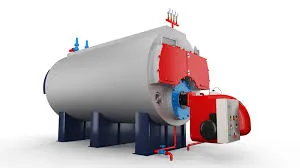

The steam boiler plays an essential role in a wide array of industrial applications, from power generation to food processing and everything in between. The efficiency and safety of operations often hinge on the proper management of boiler water levels. One innovative solution that has gained traction in recent years is the Buy Low Water Cut-off Steam Boiler. This article delves into its features, benefits, and best practices for effective implementation.

What is a Water Cut-off Steam Boiler?

A water cut-off steam boiler is an advanced boiler type designed to prevent damage by monitoring and controlling water levels inside the system. The “low water cut-off” mechanism serves as a critical safety feature, automatically shutting down the boiler when water levels drop below a predetermined threshold. This prevents the boiler from operating in a low-water condition, which can lead to overheating, boiler failure, and potential safety hazards.

How Does It Work?

The operation of a low water cut-off steam boiler involves various components such as sensors, controls, and alarms. The primary sensor measures the water level within the boiler. When the water level falls below the cut-off point, the system triggers an automatic shutoff. This not only protects the integrity of the boiler but also minimizes the risk of potentially dangerous situations often associated with inadequate water levels.

Benefits of Buy Low Water Cut-off Steam Boilers

1. Enhanced Safety Safety is paramount in any industrial setting. The implementation of a low water cut-off system significantly reduces the risk of boiler explosions or failures caused by low water levels. This added layer of safety helps comply with regulations and industry standards.

2. Protects Boiler Components Operating under low water conditions can lead to significant wear and damage to vital components of the boiler, including the burner and heat exchanger. A low water cut-off system ensures proper water levels, thereby prolonging the life of crucial boiler parts.

3. Increased Efficiency Maintaining optimal water levels can enhance the overall efficiency of the boiler. The low water cut-off system helps to ensure that the boiler runs at peak performance, minimizing energy costs and improving output.

4. Reduced Maintenance Costs By preventing damage caused by low water levels, businesses can reduce their overall maintenance costs. Frequent repairs and downtime are less likely when the boiler is equipped with a reliable low water cut-off mechanism.

buy low water cut off steam boiler

5. Operational Control Many modern low water cut-off steam boilers come with advanced control systems that allow operators to monitor boiler performance in real-time. This level of control aids in quick decision-making and fosters better operation management.

Best Practices for Implementation

To maximize the benefits of a Buy Low Water Cut-off Steam Boiler, businesses should adhere to several best practices

1. Regular Inspections Conduct routine inspections of the low water cut-off system to ensure all components are functioning correctly. Any potential issues should be addressed immediately to avoid operational delays.

2. Calibrate Sensors Correct calibration of sensors is essential to prevent false alarms or excessive shutdowns. Ensure that calibration procedures are followed, as outlined in the manufacturer’s guidelines.

3. Training for Operators Operating personnel should be adequately trained on the functions and importance of the low water cut-off system. Proper training ensures that operators can respond effectively in case of any alerts or system malfunctions.

4. Integration with Alarm Systems Consider integrating the low water cut-off system with existing alarm systems for enhanced awareness. This way, alarms can notify staff if water levels drop unexpectedly, ensuring immediate action can be taken.

5. Documentation and Compliance Keep detailed records of inspections, maintenance work, and any incidents related to the low water cut-off system. This documentation can be crucial for compliance with safety regulations and industry standards.

Conclusion

The Buy Low Water Cut-off Steam Boiler is a significant advancement in boiler technology that prioritizes safety, efficiency, and cost-effectiveness. By adopting best practices and maintaining a vigilant approach to boiler management, industries can ensure safe operations while maximizing the benefits of these innovative systems. The investment in such technology not only protects assets but also contributes to the overall sustainability of industrial operations.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025