oil steam boiler service

Oil Steam Boiler Service Ensuring Efficiency and Reliability

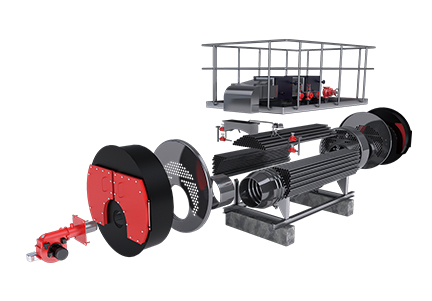

Oil steam boilers are crucial components in many industrial and commercial applications. They provide the necessary steam for processes such as heating, power generation, and even some manufacturing processes. However, like any mechanical system, they require regular maintenance and service to ensure optimal performance and prevent unexpected breakdowns.

Regular oil steam boiler service is essential for several reasons. Firstly, these boilers operate under high pressure and temperature, which can lead to wear and tear over time. A well-preserved boiler contributes to operational efficiency, which can significantly impact a facility's energy consumption and costs. By scheduling routine maintenance, operators can identify potential issues before they escalate into costly repairs or replacements.

One of the critical aspects of oil steam boiler service is cleaning. The buildup of soot, scale, and other deposits can restrict airflow and heat transfer, leading to decreased efficiency. During a service visit, technicians typically perform thorough cleaning of the burner, combustion chamber, and heat exchanger surfaces. This process not only enhances efficiency but also reduces emissions, which is increasingly important in today’s environmentally conscious world.

oil steam boiler service

Another vital component of service is the inspection of safety devices. Oil steam boilers are equipped with various safety mechanisms designed to prevent dangerous situations such as explosions or leaks. Regular checks ensure these devices are functioning correctly. Technicians typically assess pressure relief valves, low water cut-off controls, and other critical safety features to ensure they meet industry standards.

Oil quality is also significant in the upkeep of steam boilers. Poor-quality oil can lead to increased soot production, impeding boiler performance. Service technicians often check the oil supply system, including filters and pumps, and recommend necessary replacements or cleaning to maintain fuel quality. This proactive approach not only prolongs the life of the boiler but also ensures clean and efficient operation.

Moreover, regular servicing can pinpoint areas for improvement or upgrades. As technology advances, new innovations can enhance the efficiency and sustainability of oil steam boilers. Service providers can recommend modern controls or combustion technologies that may significantly reduce fuel consumption and emissions.

In conclusion, regular oil steam boiler service is not just a regulatory requirement but a strategic practice that enhances energy efficiency, safety, and overall reliability. By investing in routine maintenance, businesses can not only avoid unexpected downtimes and costly repairs but also improve their environmental footprint. As the demand for efficient and reliable energy solutions continues to grow, prioritizing oil steam boiler service will be essential for any operation reliant on steam generation.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025