High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & Quotes

- Introduction to Biomass Pellet Boiler Technology and Market Overview

- Technical Advantages and Environmental Impact

- Comparison of Leading Biomass Pellet Steam Boiler Companies

- Customized Solutions: How to Select the Right Biomass Pellet Steam Boiler

- Service and Support: Key Factors to Consider

- Real-World Applications and Success Stories

- Biomass Pellet Boiler: Shaping a Sustainable Future

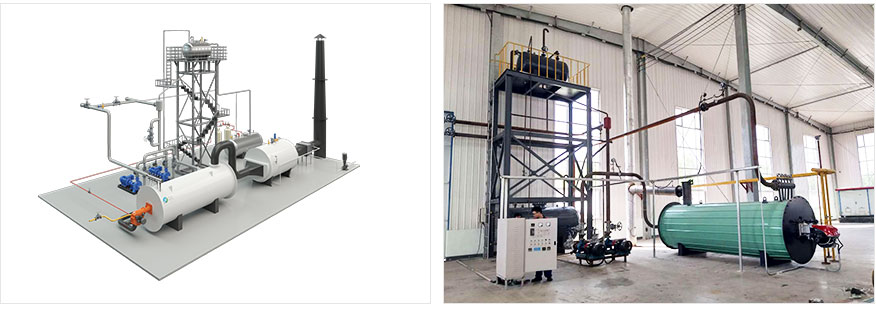

(biomass pellet boiler)

Introduction to Biomass Pellet Boiler Technology and Market Overview

The biomass pellet boiler

industry has undergone rapid transformation in recent years, emerging as a preferred alternative to conventional fossil-fuel heating systems globally. With advancements in engineering and increasing environmental regulations, the market for biomass-based energy solutions is experiencing consistent growth. According to the International Energy Agency, global biomass boiler installations have increased by 52% between 2018 and 2023, with Europe accounting for more than 40% of the new installations. North America and Asia-Pacific are following closely due to rising concerns over carbon emissions and fuel security. Government policies, including incentives for renewable heat and stricter greenhouse gas (GHG) emissions targets, have further encouraged industrial, commercial, and even residential sectors to adopt biomass pellet boilers as a core component of modern energy infrastructure.

Biomass pellet boilers convert compressed organic pellets—typically derived from wood waste, agricultural residue, or dedicated energy crops—into thermal energy through high-efficiency combustion processes. These systems are designed for diverse applications, ranging from district heating networks, manufacturing facilities, and food processing plants to institutional buildings like schools and hospitals. As demand for reliable, low-emission heat grows, so does the need for robust biomass pellet steam boiler service frameworks to keep these installations running smoothly.

Technical Advantages and Environmental Impact

Adoption of biomass pellet boilers offers significant technological and ecological benefits over traditional gas or oil-fired products. Firstly, biomass pellets possess a high energy density, with average calorific values reaching 16-18 MJ/kg, allowing for compact fuel storage and efficient heat production. Automated fuel feeding and ash removal systems minimize maintenance requirements, enhancing system uptime and reducing manual intervention compared to earlier biomass solutions.

Operational efficiency rates for modern biomass pellet steam boilers frequently exceed 88%, rivaling or surpassing fossil-fueled counterparts. Emissions reduction is another critical advantage: studies have shown that using biomass pellets can cut lifecycle carbon dioxide (CO2) emissions by up to 90% compared to coal and by more than 50% when compared to natural gas. Additionally, particulate emissions, volatile organic compounds (VOCs), and nitrogen oxide (NOx) release have been significantly mitigated due to advanced combustion controls and flue gas treatment technologies.

Sustainability is also addressed through responsible sourcing: Certification schemes such as FSC and PEFC ensure that wood-based pellets are produced from sustainably managed forests, supporting broader environmental goals. These advances not only enhance the reputation of biomass pellet boiler solutions, but also provide measurable impact for businesses aiming to align with Scope 1 and Scope 2 GHG reduction targets.

Comparison of Leading Biomass Pellet Steam Boiler Companies

As market demand has surged, so too has competition among biomass pellet steam boiler companies. To aid prospective buyers, the following table summarizes the key differentiators of four prominent industry players, focusing on critical metrics such as output capacity, system efficiency, support offerings, and warranty coverage:

| Brand | Max. Output Capacity (MW) | Efficiency (%) | Emissions Controls | Standard Warranty (Years) | Service Network |

|---|---|---|---|---|---|

| GreenHeat Solutions | 5.0 | 90 | ESP + SCR | 5 | Europe & North America |

| EcoSteam Pro | 3.2 | 88 | Baghouse + SNCR | 3 | Asia-Pacific |

| BioFlame Group | 6.0 | 91 | ESP + Fabric Filter | 6 | Global |

| EnviroPellet Tech | 4.5 | 89 | SRC + Wet Scrubber | 4 | Europe & Africa |

The technical superiority of each vendor lies in their integration of flue-gas cleaning technologies and robust service networks. For instance, BioFlame Group stands out for both its highest rated output (6.0 MW) and longest standard warranty (6 years), while GreenHeat Solutions boasts maximum efficiency and wide-reaching service coverage. This comparative data assists stakeholders in making informed decisions when requesting biomass pellet steam boiler quotes.

Customized Solutions: How to Select the Right Biomass Pellet Steam Boiler

Selecting the appropriate biomass pellet steam boiler involves a thorough needs analysis, taking into account factors such as steam demand, fuel supply logistics, available space, anticipated operational hours, and emissions regulations in the target jurisdiction. Modern manufacturers now offer fully modular systems, allowing users to specify fuel feeding mechanisms, combustion chamber sizes, and emission control add-ons to meet unique project prerequisites.

The initial stage involves quantifying the desired thermal load and peak/historical usage cycles. Following this, logistical assessments of pellet sourcing (including distance from supplier, pellet certification, and storage infrastructure) are undertaken to ensure reliable, cost-competitive fuel supply year-round. Next, the boiler room footprint, local grid conditions, and integration possibilities with existing heat exchangers must be aligned to avoid process bottlenecks and capitalize on energy efficiency.

Leading vendors increasingly provide digital twins and simulation-based design consultations, optimizing combustion profiles for site-specific pellet properties and facilitating predictive maintenance. Ensuring compatibility with building management systems (BMS) is another critical consideration for facilities prioritizing automated energy optimization.

Service and Support: Key Factors to Consider

Excellence in biomass pellet steam boiler service provision differentiates outstanding suppliers from the rest of the field. Downtime translates into lost output and costly disruptions, making high-quality aftersales support and preventive maintenance essential.

Buyers should prioritize partners offering rapid-response on-site technical teams, remote diagnostics, and comprehensive spare parts inventories. Service contracts should include annual safety checks, regulatory compliance inspections, and provisions for software/firmware updates as emissions standards evolve. Some companies, such as GreenHeat Solutions and BioFlame Group, complement their offerings with operator training programs and cloud-based performance reporting, empowering customers to proactively manage energy consumption trends and detect anomalies before escalation.

Additionally, scalable service agreements—ranging from on-demand troubleshooting to 24/7 managed operation—allow organizations to align support levels with in-house capabilities, operational complexity, and budgetary constraints.

Real-World Applications and Success Stories

The transformative potential of biomass pellet boilers is increasingly illustrated in sector-wide decarbonization efforts.

- District Heating in Denmark: Over 65% of Danish households are now connected to district heating systems, a significant proportion of which are powered by community-scale biomass pellet steam boilers. This shift has contributed to a 56% decline in GHG emissions from space heating across the country since 2005.

- Food Processing Facility in Germany: A leading frozen food producer replaced its legacy oil-fired boiler with a 4.5 MW BioFlame system. The transition reduced annual CO2 output by 7,800 metric tonnes and slashed heating costs by 28% within the first operational year. Automation streamlined boiler operations, freeing staff for core production work.

- University Hospital in Sweden: The installation of an EnviroPellet Tech boiler for centralized hospital sterilization and space heating led to a 44% improvement in boiler uptime and met stringent Nordic air quality requirements, serving as a model for hospital energy retrofits across Scandinavia.

These real-world case studies showcase the flexibility of modern solutions, their impressive sustainability metrics, and their ability to provide immediate commercial value. They also underscore the critical role that comprehensive biomass pellet steam boiler service and strong vendor relationships play in sustained operational success.

Biomass Pellet Boiler: Shaping a Sustainable Future

In conclusion, the biomass pellet boiler stands as a mature, proven technology at the forefront of the energy transition. It enables organizations to achieve dramatic carbon reduction, lower operating costs, and enhance energy security with scalable, high-efficiency systems. Robust service ecosystems and customization pave the way for tailored solutions suited to diverse operational environments, ensuring sustained value and compliance with evolving policy demands.

As manufacturing, district heating, educational, and healthcare sectors continue their decarbonization journey, the data-driven performance and rapid return on investment offered by today’s biomass pellet steam boilers are increasingly compelling. With ongoing investments in R&D, expanding service infrastructures, and emerging pellet supply innovations, the outlook for this technology remains bright. Adopting a well-supported biomass pellet boiler system—backed by transparent quotes, reputable companies, and proven service offerings—places any organization at the heart of a sustainable, low-carbon future.

(biomass pellet boiler)

FAQS on biomass pellet boiler

Q: What is a biomass pellet boiler?

A: A biomass pellet boiler is a heating system that uses compressed organic materials like wood pellets as fuel. It is an environmentally friendly alternative to fossil fuel boilers. These boilers are widely used for heating buildings and generating steam.Q: What services do biomass pellet steam boiler providers offer?

A: Biomass pellet steam boiler service providers typically offer installation, maintenance, repair, and system optimization. They also provide technical support and regular servicing to ensure efficiency and safety. Some companies may also offer fuel supply services.Q: How can I request quotes from biomass pellet steam boiler companies?

A: You can request quotes by contacting the companies directly through their websites or customer service hotlines. Many companies offer online forms where you provide your requirements for a customized quote. Comparing quotes from multiple companies helps you find the best deal.Q: What should I consider when choosing a biomass pellet steam boiler company?

A: Consider the company’s experience, certifications, service offerings, and customer reviews. Make sure they provide after-sales support and can supply parts and maintenance. Pricing and warranty terms are also important factors.Q: Why is regular biomass pellet steam boiler service important?

A: Regular service ensures the boiler operates efficiently and safely, reducing the risk of breakdowns. It can also extend the lifespan of the equipment and maintain lower fuel costs. Scheduled maintenance helps detect issues early and keeps emissions within environmental regulations.-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025

-

High-Efficiency Hotel Water Boiler - Reliable Hot Water Solutions for HotelsNewsJul.05,2025

-

High-Efficiency Industrial Boiler Plant Supplier & Factory Quality Boiler Plant ProductsNewsJul.05,2025

-

High-Efficiency House Hot Water Boiler Supplier & Factory Reliable House Hot Water Boiler Product SolutionsNewsJul.04,2025