Leading Electric Steam Boiler Manufacturers | Efficient Industrial

The Core Role of Electric Steam Boiler Manufacturers in Modern Industrial Operations

In the intricate landscape of industrial processing and energy generation, the role of reliable steam production cannot be overstated. From pharmaceutical manufacturing to large-scale textile operations, a consistent and efficient steam supply is paramount. Among the diverse range of boiler technologies, electric steam boilers are gaining significant traction due to their environmental benefits, precision control, and operational safety. Understanding the capabilities and offerings of leading electric steam boiler manufacturers is crucial for businesses aiming to optimize their energy consumption and adhere to increasingly stringent environmental regulations. This article delves into the critical aspects of electric steam boiler technology, exploring manufacturing processes, technical specifications, application scenarios, and the strategic advantages they offer to a multitude of industries.

While traditional fuel-fired boilers, such as those relying on natural gas or even solid fuels like in a wood steam boiler, have dominated the market for decades, the shift towards electrification is evident. This transition is driven by a desire to reduce carbon footprints, minimize local emissions, and leverage renewable electricity sources. Electric boilers offer a cleaner alternative, transforming electrical energy directly into heat for steam generation, often with efficiencies approaching 99%.

Emerging Trends in Industrial Steam Boiler Technology

The industrial boiler market is dynamic, influenced by technological advancements, environmental policies, and economic factors. Several key trends are shaping the future of industrial steam generation:

- Electrification and Decarbonization: A prominent trend is the increasing adoption of electric boilers as industries seek to reduce reliance on fossil fuels and achieve net-zero emissions. This is particularly relevant in regions with abundant renewable electricity.

- Enhanced Efficiency: Manufacturers are continuously innovating to improve energy efficiency, integrating advanced controls and waste heat recovery systems. This includes optimizing the design of internal components, such as the steam boiler heat exchanger, to maximize thermal transfer.

- Smart Boiler Systems: The integration of IoT (Internet of Things) and AI for predictive maintenance, remote monitoring, and real-time optimization is becoming standard. These systems can fine-tune operations, detect anomalies, and reduce downtime.

- Modular and Compact Designs: Space constraints in industrial facilities drive demand for compact, modular boiler systems that offer easier installation, scalability, and maintenance.

- Hybrid Boiler Solutions: Combining electric heating with other fuel sources (e.g., natural gas) provides operational flexibility, allowing facilities to switch based on energy prices or availability. This can be seen in offerings like a hybrid gas steam boiler for sale that also incorporates electric heating elements.

- Sustainable Materials and Manufacturing: A focus on using recyclable materials and reducing the environmental impact of the manufacturing process itself, aligning with broader corporate sustainability goals.

These trends underscore a broader commitment to sustainable, efficient, and technologically advanced industrial operations, with electric steam boilers playing a pivotal role in this evolution.

Manufacturing Process Flow of Electric Steam Boilers

The production of high-quality electric steam boilers involves a meticulous multi-stage process, ensuring durability, efficiency, and compliance with rigorous safety standards. As specialized electric steam boiler manufacturers, companies adhere to precise engineering and quality control protocols.

Schematic Manufacturing Steps:

- Material Procurement & Inspection: High-grade steel alloys (e.g., SA-516 Grade 70 for pressure vessels, ASTM A106 Grade B for piping) are sourced. Incoming materials undergo stringent inspection for chemical composition, mechanical properties, and surface integrity to meet standards like ASME Boiler and Pressure Vessel Code.

-

Component Fabrication:

- Shell & Pressure Vessel Forming: Steel plates are precisely cut using CNC plasma or laser cutting, then rolled and welded into cylindrical shells. Ends are dished and formed through hydraulic pressing.

- Heating Element Assembly: High-density, low-watt-density Incoloy or stainless steel heating elements are cast or forged to specification, ensuring optimal heat transfer and longevity.

- Piping & Fittings: Pipes are bent, cut, and prepared for welding, often utilizing orbital welding for superior joint integrity, crucial for efficient steam distribution and the steam boiler heat exchanger.

- Control Panel Integration: Microprocessor-based control systems, including PLCs, sensors, and safety interlocks, are assembled and wired. This often includes sophisticated thermostat for steam boiler functionality.

- Welding & Assembly: Critical components are welded by certified welders using techniques like TIG, MIG, or SAW, following ASME Section IX. Non-destructive testing (NDT) such as X-ray, ultrasonic, and magnetic particle inspection is performed on all critical welds to detect flaws.

- Hydrostatic Testing: The completed pressure vessel undergoes hydrostatic testing, where it is filled with water and pressurized to 1.5 times its maximum allowable working pressure (MAWP) to verify structural integrity and leak-tightness.

- Insulation & Cladding: High-efficiency thermal insulation (e.g., mineral wool, ceramic fiber) is applied to minimize heat loss, followed by durable external cladding (e.g., painted steel or stainless steel).

- Electrical & Controls Integration: All electrical components, including power distribution, heating elements, sensors, and the control panel, are meticulously wired and integrated. Comprehensive functional testing of the control system is performed.

- Final Inspection & Certification: Boilers undergo a final quality assurance check, ensuring compliance with international standards such as ISO 9001, ASME, PED (Pressure Equipment Directive), and CE marking. Third-party inspections are often conducted.

The typical service life of a well-maintained electric steam boiler often exceeds 20-30 years, attributed to the robust materials and stringent manufacturing processes. Target industries benefiting from these advanced boilers include petrochemical, pharmaceutical, food and beverage, textile, pulp and paper, and water supply & drainage systems.

In typical application scenarios, these boilers demonstrate significant advantages:

- Energy Saving: Near 100% efficiency in converting electricity to steam, minimizing energy waste compared to combustion boilers with stack losses.

- Corrosion Resistance: Use of stainless steel and special alloys for wetted parts and heating elements, enhancing longevity and reducing maintenance, particularly important in a water tube steam boiler design.

- Precise Control: Advanced control systems allow for extremely accurate temperature and pressure regulation, crucial for sensitive processes.

- Environmental Benefits: Zero direct emissions at the point of use, supporting clean air initiatives and often simplifying permitting processes.

Technical Specifications and Parameters of Electric Steam Boilers

When considering an industrial electric steam boiler, detailed technical specifications are paramount for ensuring compatibility and optimal performance for specific operational requirements. The design parameters influence everything from steam output to footprint and electrical load.

Typical Electric Steam Boiler Specifications (Example)

| Parameter | Value/Description |

|---|---|

| Steam Output Capacity | 50 kg/h to 10,000 kg/h (or 100 kW to 7,500 kW) |

| Operating Pressure | 0.7 MPa to 2.5 MPa (100 psi to 360 psi) |

| Operating Temperature | 170°C to 225°C |

| Electrical Supply | 3-phase, 400V / 480V / 600V / 690V, 50Hz / 60Hz |

| Efficiency | > 98.5% (typically 99.5% for direct immersion types) |

| Heating Elements | Incoloy 800/825 or Stainless Steel 316L |

| Control System | PLC-based with HMI, Modbus/Ethernet communication |

| Safety Features | Low water cutoff, overpressure relief, over-temperature protection, fault diagnostics |

| Standards Compliance | ASME, PED 2014/68/EU, CE, UL/CSA (where applicable) |

The specific design of the boiler, whether it's an electrode boiler or a resistance-type heater, will impact some of these parameters. Electrode boilers, for instance, are generally used for higher capacities and voltages. The proper sizing of a steam boiler industrial unit is critical to avoid under- or over-provisioning, both of which can lead to inefficiencies. A well-specified thermostat for steam boiler systems also plays a crucial role in maintaining precise temperature control, optimizing energy use, and ensuring process stability.

Diverse Application Scenarios of Electric Steam Boilers

The versatility and inherent advantages of electric steam boilers make them suitable for an extensive array of industrial and commercial applications. Their clean operation and precise control are especially valued in sensitive environments.

- Pharmaceutical & Biotechnology: Sterilization of equipment, humidification in cleanrooms, and heating of process vessels where purity is non-negotiable. Electric boilers eliminate combustion by-products, ensuring sterile environments.

- Food & Beverage Processing: Cooking, pasteurization, sterilization, and cleaning-in-place (CIP) systems. Electric boilers provide precise temperature control crucial for product quality and safety, often specified for steam boiler industrial applications requiring sanitary steam.

- Hospitals & Healthcare Facilities: Sterilization of surgical instruments, laundry operations, and space heating/humidification. Reliability and immediate steam availability are critical.

- Textile Industry: Dyeing, finishing, and drying processes that require significant amounts of consistent steam. Electric boilers offer a clean steam source that prevents fabric discoloration.

- Breweries & Distilleries: Mash cooking, sterilization of fermentation tanks, and distillation processes. Electric boilers ensure no contamination from combustion fumes.

- Laboratories & Research Institutions: Providing sterile steam for autoclaves, environmental chambers, and specialized heating applications.

- District Heating Networks: Supplementing or providing primary heat for urban heating systems, particularly in areas with renewable energy grids.

- Rubber & Plastic Molding: Heating presses and molds where precise temperature control impacts product quality.

The absence of fuel storage, flues, and combustion air requirements further simplifies installation and operation, making them an attractive option in urban or space-constrained facilities.

Key Technical Advantages of Electric Steam Boilers

Beyond their environmental benefits, electric steam boilers offer a suite of technical and operational advantages that contribute to lower lifecycle costs and improved process efficiency for industries relying on steam.

- High Energy Efficiency: Operating at near 100% efficiency, electric boilers convert almost all electrical input into heat, minimizing energy losses associated with combustion and exhaust gases. This contrasts sharply with a gas steam boiler for sale which inherently has stack losses.

- Rapid Startup and Response: Electric boilers can generate steam quickly from a cold start and respond almost instantaneously to changes in steam demand, thanks to precise electrical control. This enhances operational flexibility.

- Compact Footprint: Absence of fuel storage tanks, burners, flues, and complex air handling systems means electric boilers require significantly less space, making them ideal for facilities with limited room.

- Quiet Operation: Without combustion noise or forced draft fans, electric boilers operate much quieter than their fossil-fuel counterparts, contributing to a better working environment.

- Low Maintenance Requirements: Fewer moving parts, no fuel-related wear and tear (e.g., soot, ash, burner components), and simpler design lead to reduced maintenance intervals and costs. Regular water treatment and electrode/element checks are typically the primary requirements.

- Enhanced Safety: Elimination of explosion hazards associated with fossil fuel combustion. Modern electric boilers incorporate multiple safety interlocks and controls, often exceeding requirements for specific units like a weil mclain eg 40 steam boiler.

- Scalability: Modular designs allow for easy expansion of steam capacity by adding units, providing flexibility for growing industrial needs.

These technical advantages position electric steam boilers as a superior choice for many modern industrial steam applications, especially where sustainability, precision, and operational safety are top priorities.

Vendor Comparison: Leading Electric Steam Boiler Manufacturers

The market for industrial boilers features several reputable manufacturers, each offering unique strengths in terms of technology, capacity, and specialization. When selecting an electric steam boiler, a thorough comparison is essential. While specific product lines vary, here’s a general comparative overview focusing on key attributes for electric steam boiler manufacturers.

Comparative Analysis of Leading Boiler Types

| Feature | Electric Resistance Boiler | Electric Electrode Boiler | Traditional Fossil Fuel Boiler (e.g., Gas/Oil) |

|---|---|---|---|

| Operating Principle | Immersed resistance heating elements | Electrical current passes through boiler water (resistive heating) | Combustion of fuel (e.g., gas steam boiler for sale) heats water via heat exchanger |

| Efficiency | ~99.5% | ~99% | 80-92% (depending on design, e.g., water tube steam boiler vs. fire tube) |

| Capacity Range | Low to Medium (up to 3,000 kW) | Medium to High (up to 70,000 kW) | Very Low to Very High (up to hundreds of MW) |

| Water Purity Req. | High (for element longevity) | Specific conductivity range (water is part of circuit) | High (for boiler and steam boiler heat exchanger longevity) |

| Emissions | Zero direct emissions | Zero direct emissions | CO2, NOx, SOx, Particulates |

| Footprint | Very Compact | Compact | Large (requires fuel storage, flue gas handling) |

Beyond these technical distinctions, factors like after-sales support, spare parts availability, warranty, and lead times are critical decision points. Manufacturers often specialize; some may excel in compact solutions for a specific steam boiler industrial sector, while others focus on high-capacity electrode boilers for utility-scale applications.

Customized Solutions from Leading Manufacturers

Recognizing that no two industrial processes are identical, leading electric steam boiler manufacturers offer highly customized solutions. This bespoke approach ensures that the boiler system perfectly aligns with a client's specific operational demands, space constraints, and budget.

- Tailored Capacity and Pressure: Boilers can be designed for exact steam output and pressure requirements, from small batch processes to continuous high-volume operations. This includes specialized designs for ultra-pure steam or high-pressure applications.

- Advanced Control Integration: Custom PLC programming and HMI (Human-Machine Interface) development to seamlessly integrate with existing plant SCADA systems, enabling remote monitoring, diagnostics, and energy management. Features like smart thermostat for steam boiler systems can be configured for multi-zone control.

- Material Selection: Choice of specific alloys for internal components (e.g., SS316L for pharmaceutical applications) to ensure chemical compatibility and corrosion resistance, especially crucial in water tube steam boiler designs where water quality is a constant factor.

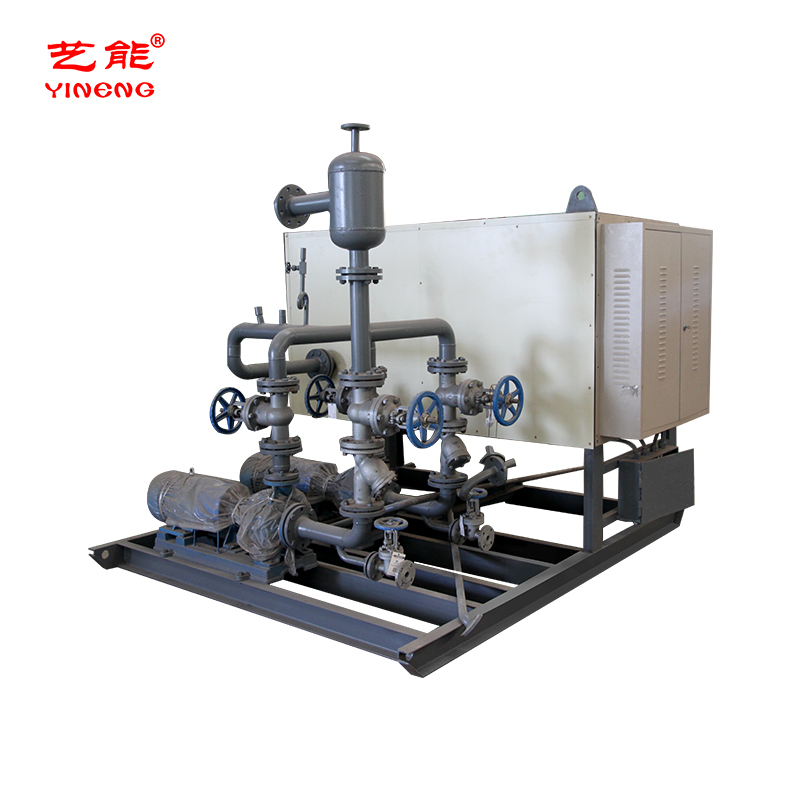

- Skid-Mounted Systems: For fast deployment and minimal on-site installation, boilers can be delivered as pre-piped, pre-wired, and pre-tested skid-mounted units, including deaerators, feed water pumps, and blowdown systems.

- Compliance and Certification: Custom designs to meet specific local codes (e.g., CSA, UL) or international certifications (e.g., ATEX for hazardous environments), which can be critical for certain sectors.

- Energy Storage Integration: Solutions can be designed to interface with thermal energy storage systems, allowing clients to heat water during off-peak electricity hours for steam generation during peak demand, optimizing energy costs.

This ability to customize ensures that clients receive not just a boiler, but a comprehensive steam generation solution engineered for their unique challenges and long-term operational success.

Application Case Studies & Customer Feedback

Real-world applications demonstrate the tangible benefits of investing in electric steam boiler technology. Here are simulated case studies showcasing diverse industrial successes:

Case Study 1: Pharmaceutical Plant Modernization

A leading pharmaceutical manufacturer in Europe sought to replace aging gas steam boiler for sale units with a cleaner, more reliable solution to meet strict cGMP (current Good Manufacturing Practice) standards. They installed a 2.5 MW electric resistance steam boiler, supplying steam for sterilization of autoclaves and process heating.

- Outcome: Achieved zero on-site emissions, significantly reduced maintenance costs by 30%, and ensured ultra-pure steam free from combustion by-products. The rapid response time of the electric boiler allowed for more efficient batch processing.

- Customer Feedback: "The transition to electric steam generation has been seamless. Our operational efficiency has improved, and we've reduced our carbon footprint, aligning perfectly with our sustainability goals. The electric steam boiler manufacturers provided excellent support." - Head of Operations, PharmaCorp EU.

Case Study 2: Dairy Processing Facility Expansion

A growing dairy producer required additional steam capacity for pasteurization and CIP systems. Due to space constraints and a desire to avoid new permits for fossil fuel combustion, they opted for two 800 kW electric steam boilers. The units were integrated with their existing steam boiler industrial control system.

- Outcome: Seamless integration and immediate increase in steam availability. The compact footprint freed up valuable floor space, and the high efficiency contributed to stable energy costs despite increased production.

- Customer Feedback: "We needed a reliable, scalable steam source without increasing our emissions footprint. The electric boilers from reputable electric steam boiler manufacturers delivered on all fronts. The quick ramp-up time has been a huge operational advantage." - Plant Manager, DairyFresh Inc.

Case Study 3: University District Heating

A major university aimed to reduce its carbon footprint by transitioning part of its campus district heating from natural gas to electricity. They installed a large-scale 10 MW electrode boiler for peak load shaving and primary heating during off-peak electricity hours.

- Outcome: Significant reduction in natural gas consumption and associated emissions. The university leveraged lower electricity tariffs during off-peak times, leading to substantial operational cost savings.

- Customer Feedback: "This strategic investment in an electric boiler from a leading electric steam boiler manufacturer has been a cornerstone of our sustainability initiative. It's robust, efficient, and aligns with our commitment to a greener campus." - Director of Facilities, State University.

Frequently Asked Questions (FAQ)

Q1: Are electric steam boilers truly more energy-efficient than fossil fuel boilers?

A1: Yes, electric boilers convert nearly 100% of electrical energy into heat for steam, as there are no stack losses, unlike fossil fuel boilers (typically 80-92% efficient). However, overall efficiency depends on the source of electricity generation.

Q2: What maintenance is required for an electric steam boiler?

A2: Electric boilers generally require less maintenance than fossil fuel units. Key tasks include regular water treatment, blowdown procedures, inspection of heating elements/electrodes, safety device checks, and calibration of the thermostat for steam boiler system. There are no burners, flues, or fuel delivery systems to maintain.

Q3: Can electric boilers handle large industrial steam demands?

A3: Absolutely. While resistance-type electric boilers are common for small to medium loads, electrode boilers are designed for very large industrial applications, capable of producing tens of thousands of pounds of steam per hour (up to 70 MW or more). Many leading electric steam boiler manufacturers offer solutions for various scales, including large steam boiler industrial requirements.

Q4: What are the primary safety considerations?

A4: Electric boilers eliminate explosion risks associated with fuel combustion. Primary safety features include robust pressure relief valves, low water cutoffs, high-temperature limit switches, overcurrent protection, and interlocks to prevent operation under unsafe conditions. Compliance with ASME, PED, and local electrical codes is standard.

Q5: How does water quality impact electric boiler performance?

A5: Water quality is crucial. For resistance boilers, poor water quality can lead to scale buildup on heating elements, reducing efficiency and element life. For electrode boilers, water conductivity is integral to the heating process itself, requiring specific treatment to maintain optimal performance. Proper water treatment, including demineralization or reverse osmosis, is essential.

Lead Time, Warranty, and After-Sales Support

Lead Time & Fulfillment

Lead times for electric steam boilers typically vary based on capacity, customization, and manufacturer production schedules. Standard models may have lead times of 8-12 weeks, while highly customized or large-scale electrode boilers can require 16-24 weeks. Electric steam boiler manufacturers often offer expedited options for critical projects. Logistics and international shipping are managed with reputable carriers to ensure timely and safe delivery worldwide, often including customs clearance support.

Warranty Commitments

Most reputable manufacturers provide a comprehensive warranty package. This typically includes a 12-month warranty from commissioning or 18 months from shipment (whichever comes first) for the entire boiler package, covering defects in materials and workmanship. Key components, such as heating elements or pressure vessels, may carry extended warranties of 2-5 years. Specific terms are detailed in the purchase agreement.

Customer Support & After-Sales Services

Robust after-sales support is a hallmark of leading electric steam boiler manufacturers. This includes:

- Technical Assistance: 24/7 hotline and online support from experienced engineers for troubleshooting and operational guidance.

- Spare Parts Availability: A readily accessible inventory of genuine spare parts to minimize downtime.

- On-Site Services: Factory-trained technicians available for installation supervision, commissioning, routine maintenance, and emergency repairs.

- Training Programs: Comprehensive training for client's operational and maintenance staff on boiler operation, safety protocols, and basic troubleshooting.

- Preventative Maintenance Contracts: Tailored service agreements to ensure optimal performance and longevity, including regular inspections and proactive component replacement.

Conclusion: The Future is Electric for Industrial Steam

The landscape of industrial steam generation is undeniably shifting towards more sustainable, efficient, and technologically advanced solutions. Electric steam boiler manufacturers are at the forefront of this transformation, providing a diverse range of products that meet stringent operational demands while significantly reducing environmental impact. From meticulous manufacturing processes to advanced control systems and comprehensive after-sales support, the industry is dedicated to delivering reliable and high-performance steam solutions.

For businesses navigating the complexities of energy transition, investing in electric steam boilers represents a strategic move towards operational excellence, regulatory compliance, and a greener future. The ongoing innovation in efficiency, smart controls, and customizable designs ensures that electric boilers will continue to play a pivotal role in industrial decarbonization efforts worldwide.

References

- U.S. Department of Energy. (2023). Steam Boilers. Retrieved from energy.gov.

- American Society of Mechanical Engineers (ASME). (2024). Boiler and Pressure Vessel Code. Retrieved from asme.org.

- International Organization for Standardization (ISO). (2024). ISO 9001: Quality management systems. Retrieved from iso.org.

- European Parliament and Council. (2014). Directive 2014/68/EU on pressure equipment (PED). Retrieved from eur-lex.europa.eu.

- International Energy Agency (IEA). (2023). Industrial Heat Electrification Technologies. Retrieved from iea.org.

-

Leading Electric Steam Boiler Manufacturers | Efficient IndustrialNewsAug.26,2025

-

Electric Steam Boiler Manufacturers: Efficient, Reliable SolutionsNewsAug.25,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial SolutionsNewsAug.24,2025

-

Reliable Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.23,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025