Top Electric Steam Boiler Manufacturers – Reliable Industrial Solutions

Explore the evolution, technology, and application of **electric steam boiler manufacturers** in the context of greener industrial heating. Hebei Yineng Boiler Co., Ltd leads innovation with a commitment to efficiency and reliability.

About Hebei Yineng Boiler Co., Ltd

- Company Name: Hebei Yineng Boiler Co., Ltd

- Website: https://www.ynboilers.com

- Phone: +8613833185003

- Email: leesonzhou@aliyun.com

- Address: Wuqiao, Hebei, China

Hebei Yineng Boiler Co., Ltd specializes in research, manufacturing, and global distribution of high-performance steam boiler systems, including electric, gas, wood, and water tube varieties. Recognized as a key contributor to the industrial boiler sector, Yineng has set industry benchmarks through advanced engineering and unwavering focus on safety and energy efficiency.

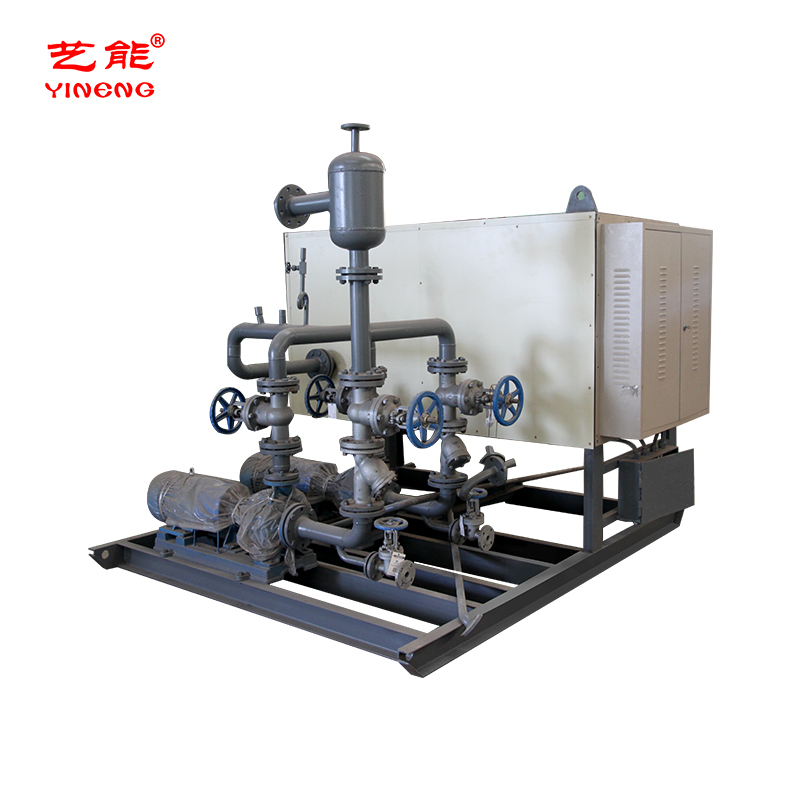

Electric Heating Thermal Oil Boiler - Product Spotlight

Product Name: Electric heating thermal oil boiler

Introduction: The Electric heating and heat transfer oil furnace is a new type of safe and energy-saving boiler. It uses high-purity heat transfer oil as the thermal medium for heat exchange, boasting excellent heat stability and rapid temperature adjustment.

Learn more: Product Detail Page

- Safe, automatic operation

- High thermal efficiency & low emissions

- Customized for industrial, commercial, and special applications

Industry Trends: Electric Steam Boiler Manufacturers

The global market for electric steam boiler manufacturers is expanding rapidly due to increased demand for clean energy solutions and more stringent emissions standards. Advanced control technologies, the integration of IoT, and modular boiler designs are reshaping efficiency standards (U.S. Dept. of Energy).

- Transition from fossil-fuel to electric and hybridized systems (Boiler Magazine)

- Increased use of heat exchangers and water tube technology for improved heat transfer

- More precise electronic thermostat integration for real-time temperature and pressure management

Technical Parameter Table: Electric Steam Boiler Manufacturers

| Manufacturer | Rated Power (kW) | Steam Output (kg/h) | Efficiency (%) | Control Mode | Key Features |

|---|---|---|---|---|---|

| Hebei Yineng Boiler Co., Ltd | 72–2160 | 100–3000 | 98–99.8 | PLC/Electronic | IoT, remote control, modular design |

| Weil-McLain | 60–1500 | 85–2100 | 97–98.5 | Digital/Analog | Thermostat integration, compact design |

| Chromalox | 16–1200 | 25–1800 | 96–98 | Smart Touch | Low maintenance, direct electric heating |

| Sussman | 36–1080 | 45–1300 | 95–98.5 | Digital | Compact modules, quick start-up |

| CERTUSS | 32–960 | 50–1300 | 96–99 | PLC | Instant steam, water tube system |

Technical Specification Trend Visualization

Technological Advancements: Electric Steam Boiler Manufacturers

Modern electric steam boiler manufacturers prioritize design innovations to meet the HVAC and industrial heating sector’s highest safety and performance standards. Notable advancements include:

- Smart Control Panels: Improved digital dashboards with real-time fault diagnostics and remote monitoring (Control Engineering).

- PLC/IoT Integration: Enables predictive maintenance and system optimization (Process Heating).

- Eco-friendly Materials: Use of high-grade stainless steel and advanced insulation for higher lifecycle value.

- Quick Start/Stop: Rapid heating via efficient heating elements and improved water tube designs.

Application Scenarios for Electric Steam Boilers

- Textile industries – dyeing, finishing, fabric steaming

- Food & beverage processing – sterilization, cooking, cleaning

- Chemical & pharmaceutical – process heating, reactor steam supply

- Commercial & institutional – HVAC, district energy (hospitals, hotels)

- Laboratory & research centers – precise steam for testing

- Paper and pulp manufacturing – process steam and paper drying

Example: The Electric heating thermal oil boiler is often chosen where precise temperature control, safety, and emission limits are paramount.

Electric Heating Thermal Oil Boiler Key Technical Indicators

- Rated Power: 72–2160 kW

- Efficiency: 99% (application dependent)

- Design Temperature: up to 320°C

- Fuel: Pure electric, high-grade heat transfer oil

- Control: PLC, smart thermostat

- Applications: Broad industrial and commercial use

Comparison with Other Boiler Types

| Type | Efficiency (%) | Operating Temp (°C) | Fuel | Emissions | Typical Application |

|---|---|---|---|---|---|

| Electric Steam Boiler | 98–99.8 | up to 320 | Electricity | None (on-site) | Cleanroom, food, pharma |

| Gas Steam Boiler | 93–97 | 250–370 | Natural Gas | Low (CO2, NOx) | Commercial, industrial |

| Water Tube Steam Boiler | 88–96 | 340–540 | Coal/Gas/Biomass | Medium–High | Heavy industry, power plants |

| Wood Steam Boiler | 82–90 | 220–350 | Wood/Biomass | Medium (PM) | Lumber, green energy |

For buyers seeking steam boiler industrial solutions, electric models offer unmatched cleanliness and automation, while gas and water tube varieties address large-scale, higher-temperature needs (ACHR News).

Frequently Asked Technical Questions

- Q1: What are the advantages of electric heating over conventional gas steam boilers for sale?

- A1: Electric systems offer immediate start-up, higher thermal efficiency, zero on-site emissions, and lower maintenance due to absence of fuel combustion components (CSE Magazine).

- Q2: What materials are commonly used for the construction of electric steam boiler industrial vessels?

- A2: Vessels are typically fabricated from carbon steel or high-grade stainless steel to withstand high pressures and prevent corrosion, ensuring durability and long operational life.

- Q3: How does a thermostat for steam boiler enhance operational safety?

- A3: Thermostats automatically regulate temperature, preventing overheating and activating safety interlocks in case of abnormal conditions, thus protecting both equipment and operators.

- Q4: What distinguishes water tube steam boiler from fire tube models?

- A4: In water tube designs, water flows through tubes heated externally by combustion gases, offering higher pressures, greater steam capacity, and faster response than fire tube models.

- Q5: What is the significance of the Weil McLain EG 40 steam boiler in the market?

- A5: The Weil McLain EG 40 is renowned for reliable home heating, featuring cast iron construction for durability and improved efficiency through updated controls.

- Q6: How do steam boiler heat exchangers contribute to system efficiency?

- A6: Heat exchangers maximize thermal energy transfer, reduce fuel consumption, and enable flexible deployment in complex industrial processes, supporting both direct and indirect steam generation.

- Q7: What standards guide the safe installation and operation of industrial electric steam boilers?

- A7: Common standards include ASME Boiler & Pressure Vessel Code, EN 12953, and local safety codes governing electrical installations, pressure testing, and control system reliability (ASME).

Conclusion: Future Prospects of Electric Steam Boiler Manufacturers

With the rise of sustainable development and green manufacturing initiatives, electric steam boiler manufacturers such as Hebei Yineng Boiler Co., Ltd are redefining industry standards in efficiency and environmental safety. Backed by strong expertise, advanced R&D, and leading-edge production processes, Yineng delivers innovative solutions recognized by industrial leaders (HeatingHelp Industry Forum, Renewable & Sustainable Energy Reviews).

If you are seeking further technical consultation, product customization, or pricing for electric steam or industrial gas steam boilers for sale, contact Hebei Yineng Boiler Co., Ltd via +8613833185003 or leesonzhou@aliyun.com. To explore the cutting-edge Electric heating thermal oil boiler, please visit our official website.

• Forum: HeatingHelp Industry Forum

• Academic: Renewable & Sustainable Energy Reviews - Boiler Efficiency

-

Top Electric Steam Boiler Manufacturers | Industrial Steam SolutionsNewsJul.26,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.25,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025