Electric Steam Boiler Manufacturers | Efficient & Clean

What I’m Seeing in the Electric Boiler Market (and a Quiet Star from Hebei)

If you’ve been tracking industrial heat like I have, you’ve noticed the pace quicken. The conversation isn’t only about steam—though it still dominates process plants—but also about thermal oil systems driven by electrification. To be honest, buyers just want reliable heat with fewer emissions and simpler permits. That’s where offerings from Electric Steam Boiler Manufacturers are morphing fast, with electric thermal oil units becoming the pragmatic, low-pressure cousin to steam.

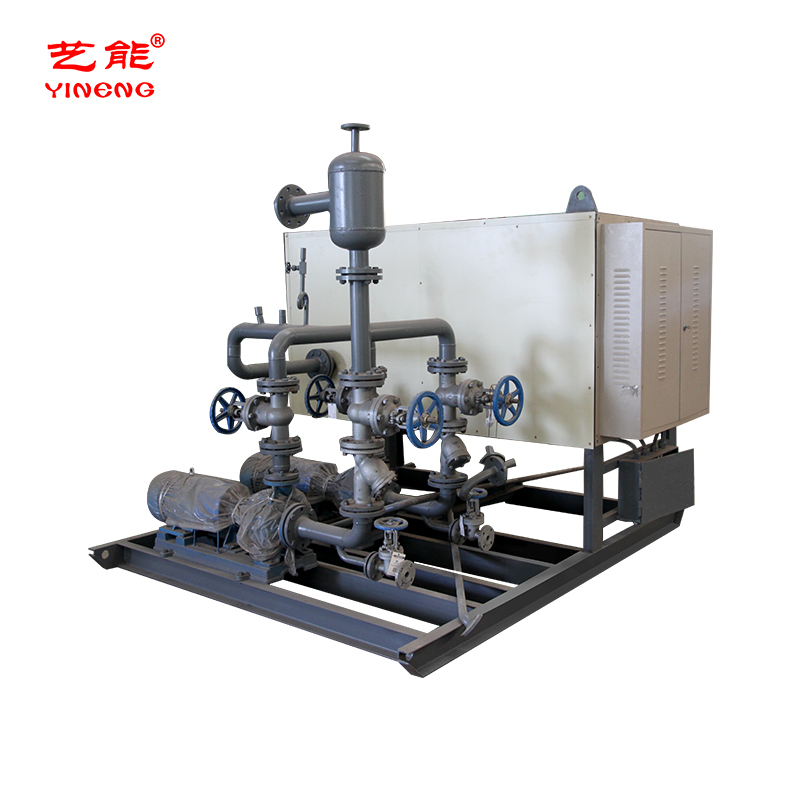

Product spotlight: Electric heating thermal oil boiler

Origin: Wuqiao, Hebei, China. This electric heating and heat transfer oil furnace uses thermal oil as the carrier, circulating in a closed loop to deliver stable heat up to around 320–350°C without the headache of a high-pressure steam permit. Many customers say the startup is “boringly predictable”—which, in boilers, is a compliment.

Typical specifications (real-world use may vary)

| Thermal capacity | 60–2,000 kW (modular to ≈10 MW) |

| Max oil temperature | ≈320–350°C (dependent on oil grade) |

| Operating pressure | Low, closed-loop (near-atmospheric) |

| Efficiency | up to 98–99% electric-to-heat |

| Voltage | 380–690V, 3-Phase (regional options) |

| Coil/Heater materials | ASTM A106 / SS304, Incoloy heaters |

| Controls | PLC + SCR, PID temp control, remote I/O |

| Certifications (typical) | CE/PED, ISO 9001; IEC/UL panels on request |

Process flow (how it’s built and proven)

- Materials: seamless coil tube, mineral-insulated heaters, high-flash-point heat transfer oil.

- Methods: TIG-welded coils, PWHT as required, hydrostatic and pressure-tightness checks.

- Controls: PLC with SIL-rated safety relays; dual high-temp cutouts; oil expansion tank.

- Testing: insulation resistance ≥10 MΩ @500V DC; leakage current per IEC 60204-1; thermal efficiency acceptance test (±1%).

- Service life: heaters 25,000–40,000 h typical; coil 10–15+ years with proper oil maintenance.

Industry trends and where it fits

Electrification is accelerating in food, pharma, textiles, chemicals, and even boutique EV battery lines. Steam still rules for humidification and CIP, but thermal oil shines for reactors, fryers, calenders, and die-heating where stable, high temperatures without condensate losses are a win. Surprisingly, payback is often driven by demand charges and night tariffs—check your utility plan before you size the bank.

Vendor landscape (snapshot)

| Vendor | Output range | Controls | Compliance | Notes |

|---|---|---|---|---|

| YNBoilers (Hebei) | 60–2,000 kW (mods to 10 MW) | PLC+SCR, remote | CE/PED, ISO 9001 | Strong on thermal oil; quick lead times |

| Chromalox | 100 kW–multi-MW | Advanced SCR | UL/CE | Global spares network |

| Fulton | 100–1,200 kW | PLC packages | ASME/CE | Known for compact electrics |

| PARAT | 0.5–10+ MW | Hybrid options | CE/PED | Marine and industrial focus |

Note: ranges and compliance are indicative; check current data sheets.

Customization and real-world feedback

- Options: explosion-proof panels, heat tracing, dual-circuit coils, Modbus/Profinet gateways.

- Test data (typical): step response to setpoint 180→250°C in ≈12–18 min; panel noise ≤65 dB; standby losses ≤1.5%/h.

- Customer remarks: “no water treatment, no blowdown—maintenance is bliss,” as one textiles manager told me.

Case notes

A Hebei food processor swapped a 1 t/h diesel steam setup for a 900 kW electric thermal oil unit. Energy use shifted to off-peak via a smart tariff; operators liked the tight ±1°C control on fryers. A European composites line, meanwhile, used a 1.2 MW system to drive platen presses at 285°C—no condensate hassles, fewer leaks. It seems that for many plants, Electric Steam Boiler Manufacturers now compete with (or offer) thermal oil as a parallel pathway to decarbonize.

Standards to look for

Ask vendors about ASME or EN fabrication, IEC 60204-1 electrical safety, DIN 4754 for thermal oil, and panel certifications (UL-508A/CE). For steam skids, ASME Section I or IV remains the reference; for oil heaters, PED/CE and a proper safety chain are non-negotiable.

Sources

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025