Electric Steam Boiler Manufacturers | Efficient & Clean

electric steam boiler manufacturers is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of boilers and auxiliary equipment. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- electric steam boiler manufacturers Overview

- Benefits & Use Cases of electric steam boiler manufacturers in Manufacturing of boilers and auxiliary equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on electric steam boiler manufacturers from Hebei Yineng Boiler Co., Ltd

electric steam boiler manufacturers Overview

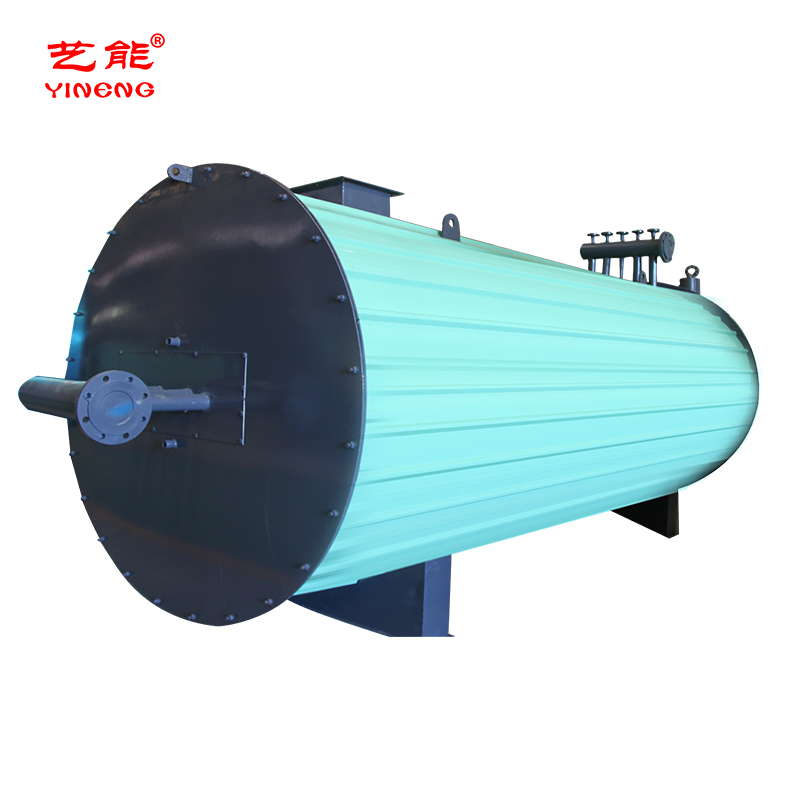

For B2B decision makers, electric steam boiler manufacturers are strategic partners in achieving reliable, high-purity steam with minimal onsite emissions and a compact footprint. Electric steam systems convert electrical energy directly into thermal energy using immersion elements or electrode technology, eliminating burners and fuel trains. Typical specifications include rapid start-up, high turndown, precise pressure control via an integrated thermostat for steam boiler logic, and efficiencies approaching the point-of-use due to limited stack losses. In process-critical lines, a well-engineered steam boiler heat exchanger ensures stable heat transfer to downstream applications such as CIP, sterilization, and curing.

Hebei Yineng Boiler Co., Ltd brings a comprehensive perspective as a proven manufacturer across electric, gas, oil, and thermal-fluid solutions. While many buyers explore a gas steam boiler for sale, a steam boiler industrial portfolio should also evaluate electric options for facilities with favorable power tariffs or decarbonization goals. Yineng’s engineering depth spans fire-tube and water tube steam boiler designs, alongside auxiliary equipment that streamlines installation and operations. A common deployment is a skid-mounted electric package delivering clean saturated steam for a plating or electronics line—compact, quiet, and easy to integrate with plant utilities and automation frameworks.

Benefits & Use Cases of electric steam boiler manufacturers in Manufacturing of boilers and auxiliary equipment

In the Manufacturing of boilers and auxiliary equipment sector, electric steam boiler manufacturers support diverse use cases: component preheating, coil curing, hydrotest temperature control, surface treatment, and lab/bench testing. Electric packages excel where fast response, low noise, and clean-room compatibility matter—such as in pharmaceuticals, F&B, precision electronics, and specialty chemicals. With no combustion air or flue, siting is flexible and mechanical rooms remain cleaner, simplifying compliance and maintenance.

- Competitive advantages: near-instant steam, tight pressure control, compact footprint, and seamless PLC/SCADA integration. Advanced controls act like a thermostat for steam boiler systems, stabilizing loads and protecting elements.

- Flexible portfolios: where electric is not optimal, Yineng also advises on robust alternatives—e.g., a high-efficiency gas steam boiler for sale, biomass/wood steam boiler solutions, or water tube steam boiler packages for higher pressures and large steam volumes.

- Interoperability: from steam boiler heat exchanger options to blowdown, feedwater, and condensate systems, Hebei Yineng Boiler Co., Ltd ensures component compatibility and lifecycle support for steam boiler industrial duty.

Buyers comparing legacy units (such as a weil mclain eg 40 steam boiler in building systems) with modern industrial solutions will find that Yineng tailors designs to process demands—whether a compact electric skid or a thermal-fluid system for high-temperature duties.

Cost, Maintenance & User Experience

Total cost of ownership for electric steam solutions typically shifts spend from mechanical complexity to energy cost. CapEx can be lower due to simplified installation—no chimney, gas piping, or burner management. OpEx depends on electricity tariffs and demand charges; however, many plants offset this with lower maintenance, high uptime, and predictable performance. In clean production areas, the absence of combustion byproducts often reduces ancillary ventilation and compliance costs.

- Maintenance: fewer moving parts, no burner tuning, and straightforward element checks. Water treatment is essential; pairing with appropriate feedwater systems extends the life of the steam boiler heat exchanger and heating elements.

- Controls: integrated PLC and a responsive thermostat for steam boiler logic minimize cycling, improving element life and energy efficiency. Remote monitoring aids predictive maintenance.

- Feedback: General equipment manufacturing clients report consistent steam quality, faster changeovers, and easier operator training. Where loads vary widely, Yineng designs with staged elements or modular skids to maintain turndown without oversizing.

For facilities where electricity pricing is unfavorable, Hebei Yineng Boiler Co., Ltd can quantify ROI between electric, gas, and biomass options—whether a gas steam boiler for sale package, a wood steam boiler system, or a water tube steam boiler for high-capacity lines—to ensure the best lifecycle economics.

Sustainability & Market Trends in manufacturing

Global manufacturing is accelerating electrification to meet carbon targets, respond to carbon pricing, and satisfy customer Scope 1/2/3 expectations. Electric steam boiler manufacturers enable low on-site emissions and streamlined permitting. At the same time, regional energy mixes differ; where grids are decarbonizing, electric steam becomes a powerful lever for net-zero roadmaps. In parallel, advanced thermal systems—such as gas/oil-fired molten salt boilers—offer precise high-temperature heat transfer, thermal inertia, and process stability for applications that exceed steam temperature limits.

- Regulatory drivers: efficiency standards, safety codes, and emissions policies encourage clean, right-sized systems, digital controls, and heat recovery via an optimized steam boiler heat exchanger.

- Market direction: hybrid strategies—electric for baseload, complemented by a gas steam boiler for sale or biomass/wood steam boiler for peak loads—are gaining traction, balancing cost, resilience, and carbon reduction.

- Hebei Yineng Boiler Co., Ltd positions customers for the future with a broad, integrable portfolio. Explore the gas-oil-fired molten salt boiler solution here: product page, designed for stable, high-temperature service within modern, efficient plants.

Conclusion on electric steam boiler manufacturers from Hebei Yineng Boiler Co., Ltd

Electric steam boiler manufacturers play a critical role in delivering clean, controllable steam for modern factories. For the General equipment manufacturing industry and Manufacturing of boilers and auxiliary equipment, partnering with Hebei Yineng Boiler Co., Ltd means access to electric, gas, oil, biomass, and thermal-fluid expertise—plus integrated auxiliaries to maximize uptime and lifecycle value. From steam boiler industrial applications to specialized systems with a robust steam boiler heat exchanger, Yineng tailors solutions to your KPIs for safety, efficiency, and sustainability.

- Ready to evaluate options—from electric packages to a gas steam boiler for sale or molten salt systems? Contact us: email: leesonzhou@aliyun.com

- Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025