Electric Steam Boiler Manufacturers | Efficient, Custom-Built

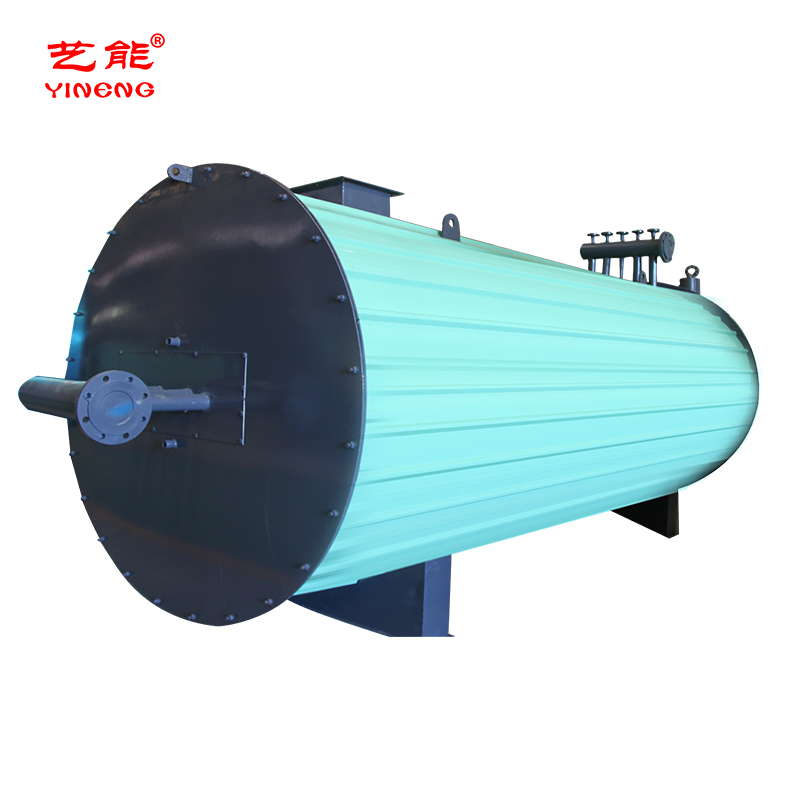

Electric Steam Boiler Manufacturers is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of boilers and auxiliary equipment. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Electric Steam Boiler Manufacturers Overview

- Benefits & Use Cases of Electric Steam Boiler Manufacturers in Manufacturing of boilers and auxiliary equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Electric Steam Boiler Manufacturers from Hebei Yineng Boiler Co., Ltd

Electric Steam Boiler Manufacturers Overview

For B2B decision makers, selecting the right Electric Steam Boiler Manufacturers is about uptime, precision, and lifecycle value. Electric steam boilers convert electrical energy into saturated steam using high-efficiency resistance elements and robust control systems. Typical industrial specifications include 0.2–20 t/h steam capacity, working pressures up to 1.6 MPa, and system efficiency up to 98% at point of use. Unlike a gas steam boiler for sale, electric units require no burner management, flue stack, or fuel storage—simplifying installation and compliance.

Core subsystems include a steam boiler heat exchanger section (pressure vessel), electric heating elements, feedwater and blowdown trains, and automation featuring PLC/HMI with step or thyristor modulation. Options such as a thermostat for steam boiler loops, soft-start to limit inrush current, and remote monitoring integrate seamlessly with plant DCS. For higher pressures and flows, complementary solutions like a water tube steam boiler remain relevant, while electric packages excel in cleanrooms, pharma, F&B, electronics, and labs where zero on-site emissions and fast start-up matter most.

Hebei Yineng Boiler Co., Ltd designs and manufactures a complete portfolio—from electric steam boiler industrial packages to oil/gas-fired and thermal systems—engineered to GB/ASME codes. Their depth across technologies ensures a right-fit solution, whether you’re specifying an electric unit, evaluating a wood steam boiler for off-grid heat, or integrating with existing assets.

Benefits & Use Cases of Electric Steam Boiler Manufacturers in Manufacturing of boilers and auxiliary equipment

In the Manufacturing of boilers and auxiliary equipment, electric steam systems act as primary boilers, test stand steam sources, or supplemental units for peak shaving and maintenance bypass. Applications include component hydro/steam testing, coil and vessel passivation, valve skid validation, sterilization, CIP/SIP, precision drying, and jacketed reactor heating. Because electric units deliver near-instant steam with tight temperature/pressure control, they pair well with sensitive processes and R&D lines where repeatability is critical.

- Fast start/stop and high turndown for agile production scheduling; minimal standby loss compared to continuous-fired units.

- Clean, silent operation with no on-site combustion—ideal for urban facilities and heat-recovery integration with a steam boiler heat exchanger.

- Lower mechanical complexity: no burners, fuel trains, or stack permits; simpler maintenance than many steam boiler industrial alternatives.

- Smart controls: PID modulation, staged elements, and thermostat for steam boiler loops ensure stable output and energy efficiency.

Hebei Yineng Boiler Co., Ltd leverages multi-technology expertise to help customers compare options objectively—electric versus water tube steam boiler, hybrid plants with a gas steam boiler for sale as backup, or biomass/wood steam boiler routes. Even when evaluating legacy references like a Weil-McLain EG 40 steam boiler for basic steam needs, Yineng’s engineering team can map a modern, scalable, and compliant path forward.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) for electric steam boilers hinges on electricity rates, demand charges, utilization, and potential time-of-use arbitrage. Capex is often lower due to simpler mechanical systems (no fuel trains or stacks). Opex can be highly competitive when paired with renewable PPAs, off-peak tariffs, or waste-heat recovery via a steam boiler heat exchanger. Many facilities realize ROI through reduced maintenance, improved safety compliance, and lower permitting overheads, plus space savings that free valuable floor area.

- Durability: industrial-grade pressure vessels, corrosion control, and quality feedwater practices support long service life.

- Maintenance: element inspection/replacement is predictable; no burner tuning, refractory work, or stack testing cycles required.

- User experience: operators value quiet operation, PLC/HMI diagnostics, and straightforward setpoint control with a thermostat for steam boiler loops.

Customers in the General equipment manufacturing industry report shorter commissioning times and fewer unplanned outages compared to some fired units. Where process loads fluctuate, staged/thyristor control limits inrush and aligns power draw with production, enhancing asset utilization. For mixed-technology sites, Hebei Yineng Boiler Co., Ltd can configure hybrid plants—electric for precision/clean steam and a water tube steam boiler for baseload—delivering resilience and optimized TCO.

Sustainability & Market Trends in manufacturing

Electrification is reshaping process heat as organizations pursue net-zero pathways, respond to carbon pricing, and future-proof operations. Electric steam boilers eliminate on-site NOx, SOx, and CO2 from combustion and simplify compliance with tightening local air-quality rules. Pairing with renewable electricity further reduces Scope 1 and 2 emissions, while demand-response strategies and thermal storage flatten peaks and control utility costs. The market also shows growing interest in hybrid configurations that keep a gas steam boiler for sale as standby for resilience or rate volatility.

Hebei Yineng Boiler Co., Ltd positions clients ahead of the curve with digital-ready controls, remote monitoring, and integration options for heat recovery, including steam boiler heat exchanger retrofits. Whether a facility needs clean electric steam, a high-pressure water tube steam boiler for heavy loads, or a biomass/wood steam boiler where biofuels are abundant, Yineng’s engineering-first approach helps balance ESG goals with pragmatic Capex/Opex considerations—delivering measurable sustainability without sacrificing reliability.

Conclusion on Electric Steam Boiler Manufacturers from Hebei Yineng Boiler Co., Ltd

For manufacturing leaders, choosing the right Electric Steam Boiler Manufacturers means securing cleaner operations, tighter control, and dependable uptime. Electric units complement or replace traditional steam boiler industrial assets, integrate with thermostats and heat exchangers, and align with modern sustainability targets. Hebei Yineng Boiler Co., Ltd stands out for multi-technology depth, rigorous quality, and application-driven engineering that de-risks procurement and accelerates ROI.

- Partner with a manufacturer that understands electric, fired, and hybrid steam ecosystems.

- Leverage optimized TCO, compliance confidence, and a future-ready controls architecture.

- Contact us: email: leesonzhou@aliyun.com - Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025