Electric Steam Boiler Manufacturers: Efficient, Custom-Built

Electric Steam Boiler Manufacturers: what buyers are really asking in 2025

If you’re shortlisting Electric Steam Boiler Manufacturers, you’re probably also weighing hybrid heat and high-temperature options. Actually, many plants do. One example that keeps popping up in my notebook is the Gas oil fired molten salt boiler from Wuqiao, Hebei, China—wet‑back internal combustion, two-pass, compact, and surprisingly efficient for a fired unit. Different tool, different job; but the comparison helps buyers cut through noise.

Market pulse

Electrification is still accelerating—driven by RE100 targets, carbon pricing, and cleaner grids. Electrode and resistance boilers deliver ≈99% element-to-steam efficiency and almost zero local emissions. However (and I guess this is the wrinkle), when you need 350–550°C process heat, electric steam isn’t always the neat fit; that’s where molten-salt loops or thermal-oil and fired systems compete.

Quick vendor landscape

| Vendor type | Typical capacity | Efficiency | Controls | Certifications | Lead time |

|---|---|---|---|---|---|

| Tier‑1 global (electric steam) | ≈0.5–50 t/h | 98–99% (element) | PLC/SCADA, energy metering | ASME/CE, UL 834 | 8–20 weeks |

| Specialist industrial (electric) | ≈200–10,000 kg/h | ≈99% | Compact HMI, cloud option | CE/ISO 9001 | 6–12 weeks |

| Chinese OEM (Wuqiao, Hebei) | Custom | 95%+ fired; 98%+ electric lines | PLC, redundancy options | ISO 9001; CE; ASME on request | 4–10 weeks (typ.) |

Buyers tell me the differentiators are: grid capacity, steam purity needs (CIP/SIP), turndown, and maintenance crew familiarity. And, to be honest, after-sales support still outweighs brochure specs.

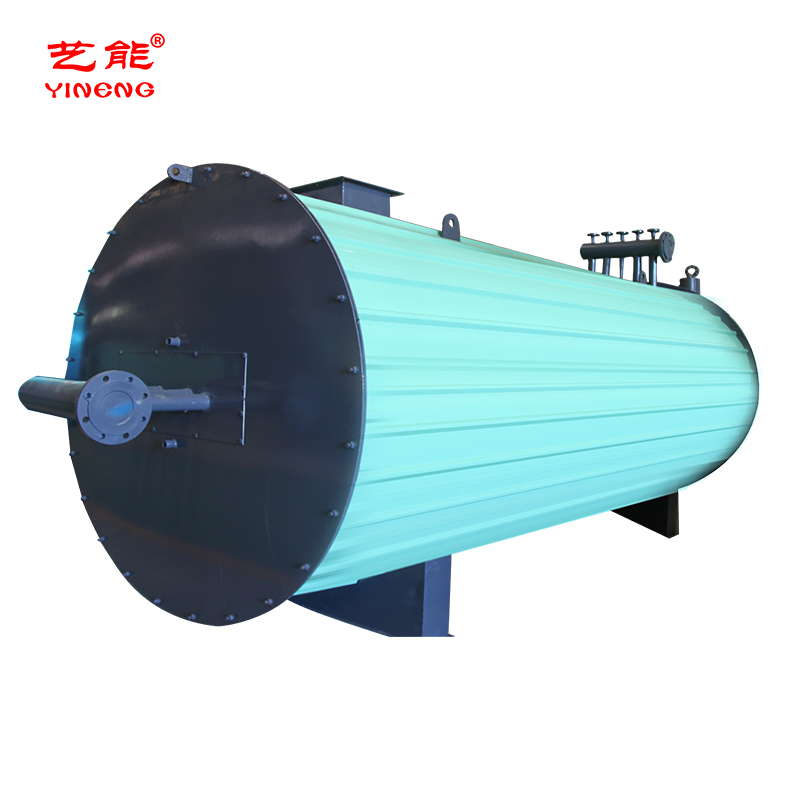

Product spotlight: Gas oil fired molten salt boiler

Origin: Wuqiao, Hebei, China. Structure: wet‑back, internal combustion, two-pass—compact, good heat transfer, and stable for high‑temp loops.

| Heat carrier | Molten salt (e.g., 60/40 nitrates) |

| Design temp/pressure | Up to ≈530°C; loop pressure low (static) |

| Thermal efficiency | ≈92–96% (real‑world may vary) |

| Fuel | Gas or light oil, low‑NOx burners |

| Materials | Pressure parts Q345R/SA‑516‑70; 304/316L on wetted ancillaries (as specified) |

| Emissions | Low‑NOx ≈30–80 mg/Nm³ with appropriate burner |

| Controls | PLC, interlocks, salt freeze‑protection logic |

| Standards/testing | Hydrostatic 1.5× design; RT/UT on welds; EN 12953/ASME BPVC alignment |

| Service life | ≈15–20 years with routine maintenance |

Process flow and QA (what I look for)

- Materials traceability: MTCs for Q345R/SA‑516‑70; valves with EN/ASME stamps.

- Welding: SAW on shells, GTAW/GMAW on nozzles; PWHT where required; NDE plan (RT/UT/MT).

- Hydrotest: 1.5× design; functional FAT: burners, safeties, interlocks, PLC I/O.

- Salt handling: dry‑out procedure, gradual heat‑up, freeze‑protection redundancy.

Applications and how to choose

Pick electric steam when you need clean steam for pharma, food, labs, and quick cycling. Choose molten salt when processes want steady 350–550°C: chemicals, resins, salt baths, CSP auxiliaries, and some textile heat‑setting. Many customers say hybrids (electric for base, fired for peaks) are a practical bridge while the grid catches up.

Customization and support

Serious Electric Steam Boiler Manufacturers offer: voltage options (400–690 V), electrode or resistance elements (Incoloy), stainless separators for clean steam, blowdown heat recovery, and fully documented water‑treatment programs. On the molten‑salt side: custom skids, dual pumps, heat‑tracing, and SIL‑rated safety loops. Certifications typically include ISO 9001, CE; UL 834 for electric assemblies; ASME U‑stamp on request.

Mini case notes

- Northern EU pharma: 2× electric units ≈1 t/h each; reported faster SIP cycles and quieter operation (internal client data, real‑world may vary).

- East Asia resins line: molten‑salt unit stabilized around 480°C, tighter control ±2–3°C; maintenance team liked the wet‑back layout for access.

Final thought: shortlist at least three Electric Steam Boiler Manufacturers, ask for a written test plan, and request efficiency data under your actual load profile. Sounds basic, but it filters the marketing fluff quickly.

References

- ASME Boiler & Pressure Vessel Code (BPVC), Section I & VIII. https://www.asme.org/codes-standards

- EN 12953: Shell boilers. https://standards.cencenelec.eu

- UL 834: Heating, Water Supply, and Power Boilers—Electric. https://ulstandards.ul.com

- IAPWS Industrial Formulation for the Thermodynamic Properties of Water and Steam. http://www.iapws.org

- IEA. Electrification of heat in industry (briefing). https://www.iea.org

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025