Electric Steam Boiler Manufacturers | Efficient, OEM, UL

Electric Steam Boiler Manufacturers is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of boilers and auxiliary equipment. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Electric Steam Boiler Manufacturers Overview

- Benefits & Use Cases of Electric Steam Boiler Manufacturers in Manufacturing of boilers and auxiliary equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Electric Steam Boiler Manufacturers from Hebei Yineng Boiler Co., Ltd

Electric Steam Boiler Manufacturers Overview

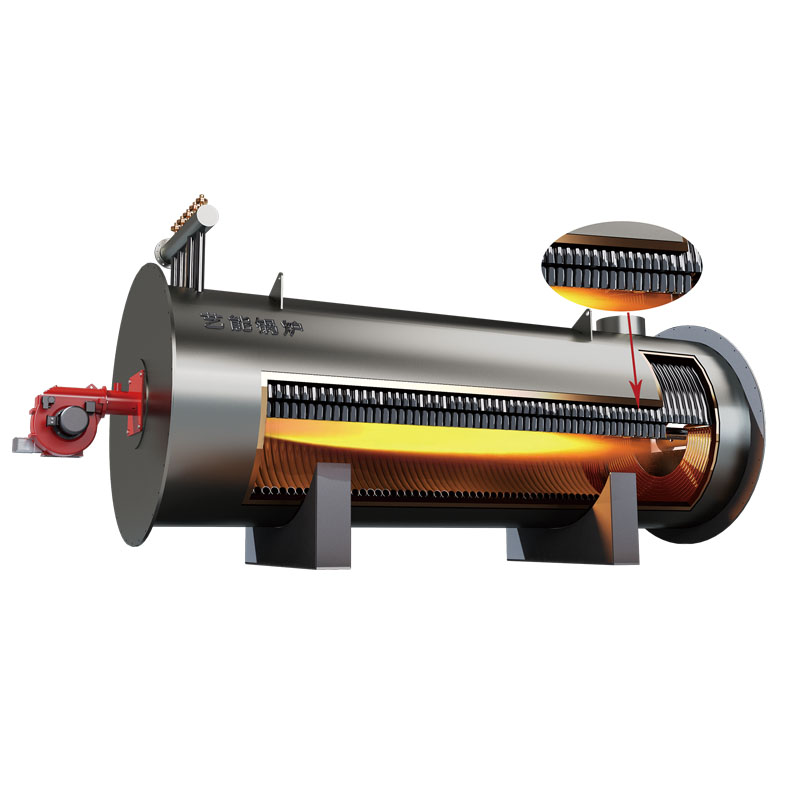

Electric steam boilers convert electrical energy into heat using immersion elements or electrode technology to generate clean, on-demand steam. In the General equipment manufacturing industry and the Manufacturing of boilers and auxiliary equipment, they are valued for rapid start-up, compact footprints, low noise, and near-zero point-of-use emissions. Compared with combustion-fired units (for example, a water tube steam boiler or a wood steam boiler), electric systems eliminate burners, fuel trains, and stacks, simplifying installation and plant layout. Critical components such as the steam boiler heat exchanger (for process-side energy transfer) and a precise thermostat for steam boiler control ensure tight temperature and pressure stability for “steam boiler industrial” duty cycles.

Hebei Yineng Boiler Co., Ltd designs and supplies integrated heat solutions for B2B clients, including electric steam options and complementary thermal systems. Their portfolio also includes high-efficiency oil/gas-fired thermal oil heaters—see the YQW gas/oil-fired thermal oil boiler—which can work alongside electric units to optimize plant utilities. Whether you’re exploring a gas steam boiler for sale to supplement capacity or benchmarking familiar names like the Weil McLain EG 40 steam boiler, Hebei Yineng focuses on application-fit engineering, robust materials, and dependable after-sales support for long-life, low-risk operations.

Benefits & Use Cases of Electric Steam Boiler Manufacturers in Manufacturing of boilers and auxiliary equipment

Electric steam systems excel in auxiliary equipment fabrication, surface treatment lines, precision cleaning, vulcanization, jacketed mixing, and HVAC humidification. For boiler-plant OEMs and integrators, electric units serve as test benches, standby/peaking boilers, and safe commissioning tools where open flames are restricted. When paired with a dedicated steam boiler heat exchanger, they deliver stable thermal energy to reactors, autoclaves, and plate heat exchange skids with tight pressure control. PLC/SCADA integration and advanced thermostat for steam boiler logic enable remote monitoring, load scheduling, and demand-limiting to reduce peak electricity costs.

Key advantages include fast start/stop, minimal venting requirements, no fuel storage, low NOx/CO at point of use, and simplified maintenance versus burner-based water tube steam boiler designs. Hebei Yineng Boiler Co., Ltd combines these electric benefits with a broad portfolio—spanning “steam boiler industrial” duty and thermal oil heaters—to architect hybrid systems that balance OPEX and reliability. If your facility already operates biomass or wood steam boiler assets, Yineng can help you stage them with electric capacity for cleaner baseload and combustion-fired backup. For users comparing a gas steam boiler for sale with electrification, Yineng’s engineering team will model steam load profiles, power tariffs, and lifecycle costs to guide the optimal path.

Cost, Maintenance & User Experience

Total cost of ownership for electric steam boilers is driven by power tariffs, duty cycle, and water quality. While electricity may cost more per unit energy than natural gas in some regions, savings accrue from lower installation costs (no flue, gas trains, or combustion air), fewer compliance requirements, and reduced maintenance—no burners to tune, fewer moving parts, and simple heating elements. With proper feedwater conditioning and blowdown practices, heating element life is extended and scaling minimized, protecting the steam boiler heat exchanger and downstream process equipment. For many “steam boiler industrial” users, the combination of uptime and cleanliness translates into a solid ROI, especially where carbon pricing, air permits, or safety policies constrain fuel-fired systems.

B2B customers in the General equipment manufacturing industry report consistent steam quality, quieter operations, and clean mechanical rooms. Power-management features—such as staged elements, soft-start, and thermostat for steam boiler setpoint recipes—help flatten demand spikes. Hebei Yineng Boiler Co., Ltd supports lifecycle performance with application engineering, commissioning guidance, operator training, and spare-parts availability. For sites evaluating a gas steam boiler for sale as a parallel solution, Yineng can compare scenarios that include hybrid plants with thermal oil systems to reduce operating costs while preserving process flexibility.

Sustainability & Market Trends in manufacturing

Industrial steam is undergoing rapid electrification as manufacturers pursue decarbonization, digitalization, and compliance with evolving air-quality and workplace-safety regulations. Electric steam boilers enable zero on-site combustion, simplify permitting, and unlock synergy with renewable power, energy storage, and demand-response programs. Many enterprises are rebalancing fleets that include legacy water tube steam boiler or wood steam boiler assets by adding electric capacity for baseload or clean standby. Meanwhile, process intensification and heat-recovery projects (via a dedicated steam boiler heat exchanger) further reduce energy intensity and operating emissions.

Hebei Yineng Boiler Co., Ltd positions customers for these shifts with modular equipment, smart controls, and integrated thermal packages. Their engineering-led approach helps B2B decision makers align capex with ESG targets and operational resilience. Whether you are benchmarking familiar references like the Weil McLain EG 40 steam boiler or comparing a gas steam boiler for sale to electrified options, Yineng provides data-driven guidance to future-proof your plant. Pairing electric steam with the company’s high-efficiency thermal oil heaters creates a flexible, low-emission utility backbone ready for market and regulatory changes.

Conclusion on Electric Steam Boiler Manufacturers from Hebei Yineng Boiler Co., Ltd

For the Manufacturing of boilers and auxiliary equipment, partnering with experienced Electric Steam Boiler Manufacturers delivers reliable steam, streamlined compliance, and lower maintenance. Hebei Yineng Boiler Co., Ltd combines electric solutions with complementary systems—such as high-efficiency thermal oil heaters—to tailor the ideal balance of performance, cost, and sustainability. From process heating to test stands and hybrid plants, Yineng’s engineering support helps B2B leaders make confident, future-ready decisions. Contact us: email: leesonzhou@aliyun.com. Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025