Electric Steam Boiler Manufacturers | Efficient & Reliable

What buyers really ask me about electric steam boiler manufacturers (and one high-heat alternative worth noting)

If you’ve been comparing electric steam boiler manufacturers lately, you’re not alone. In fact, the market’s split: plants chasing decarbonization love electric systems for precision and low on-site emissions; others still need ultra‑high temperatures or specific heat-transfer media where electric can struggle. That’s where I look at thermal oil and molten salt systems as a complementary lane—especially for chemical processing and CSP-like duties.

Quick trend check: utilities are incentivizing electrification; meanwhile, gas prices and carbon pricing swing like a pendulum. Decision-makers tell me they want “options with proof.” Fair. Let’s dig into specs, testing, and what real operators say.

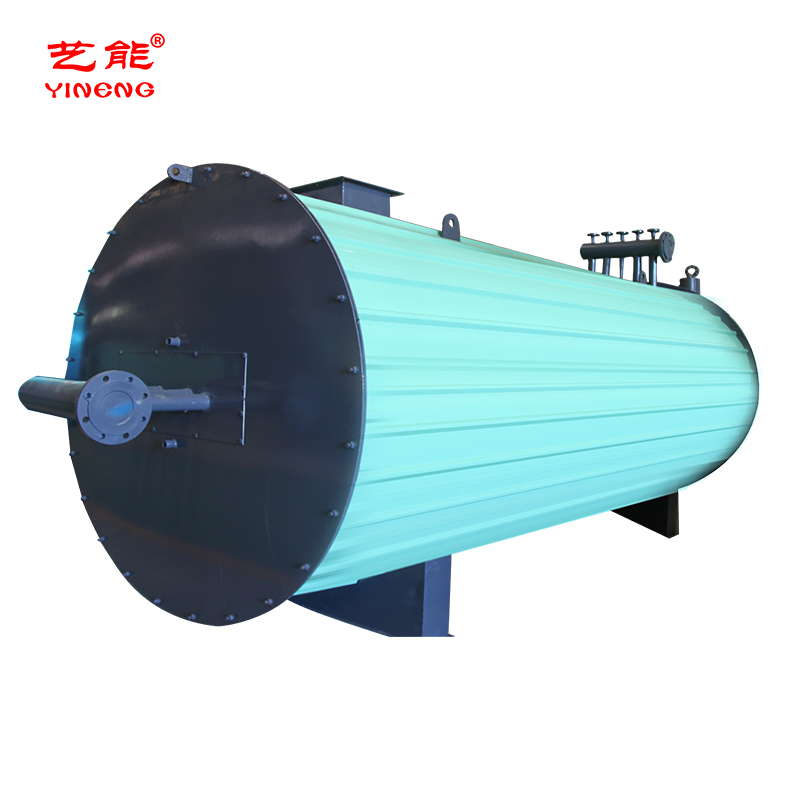

A high-heat option from Hebei: Gas oil fired molten salt boiler

Originating from Wuqiao, Hebei, China, this unit adopts a wet-back internal combustion two-pass structure. That’s engineer-speak for: compact layout, robust heat transfer, and easier tube maintenance. Honestly, I’ve seen wet-back shells quietly rack up long service lives when water chemistry and burner tuning are kept in check.

Typical product specs (field-verified ranges)

| Parameter | Typical value (≈, real-world may vary) |

| Heat medium | Molten salt (nitrate blend) up to ≈ 450–530°C service |

| Structure | Wet-back, internal combustion, two-pass |

| Efficiency (LHV) | ≈ 92–94% with proper excess air and insulation |

| Fuel | Natural gas or light oil; low-NOx burner optional (<80 mg/Nm³) |

| Design pressure | Typically 0.8–1.6 MPa for coil/outer shell sections |

| Materials | SA‑516 Gr.70 shell; 304/316L or equivalent for coils/manifolds |

Process flow, testing, and service life

Materials incoming (mill certs checked) → coil winding/rolling → welding (WPS/PQR qualified) → NDT (RT/UT on weld seams) → hydrotest at 1.5× design pressure → thermal stress run-in with salt → controls FAT. Standards typically referenced: ASME Section I/PG/IX, EN 12952/12953, GB/T 16508; control logic can follow IEC 61508 guidelines. With decent water/salt management, many customers report 15–20 years service, sometimes more.

Where electric steam shines (and where molten salt still wins)

- Electric steam: food & beverage CIP, pharma sterilization, labs, textiles, humidification—fast response, 98%+ point-of-use efficiency, simple permitting.

- Molten salt: chemical reactors, thermal storage, resin/polymer lines—stable high temps above typical steam limits, excellent thermal inertia.

One maintenance manager told me, “Our electric skid is perfect for batching and nights, but the salt loop anchors the high-heat day shift.” That hybrid thinking is increasingly common among buyers vetting electric steam boiler manufacturers.

Vendor comparison (what I actually look at)

| Vendor type | Certifications | Lead time | After‑sales | Notes |

| Tier‑1 Global (electric) | ASME S/U, CE/PED, UL 508A, ISO 9001 | 10–20 weeks | 24/7, global parts | Premium pricing; impeccable documentation |

| Hebei Specialist (molten salt/thermal) | ASME/GB/T, CE, ISO 9001 | 6–12 weeks | Remote + on‑site commissioning | Strong cost‑performance; customization friendly |

| Value OEM (electric) | CE, ISO 9001 (check scope) | 4–10 weeks | Email-based; spares vary | Great price; verify controls and wiring to UL/IEC |

Customization and real test data

On molten salt systems: custom coil metallurgy, dual-fuel burners, SIL‑rated trips, and heat‑trace packages are common. Factory FATs I’ve seen included hydro at 1.5×, burner tuning at λ≈1.1–1.2, shell skin-loss checks, and step-load tests to confirm ramp rates. For electric units from top electric steam boiler manufacturers, expect steam dryness ≥99%, turndown via SCR, and panel builds to UL 508A/IEC 60204.

Case snapshots

- Textile mill: replaced two gas fire-tubes with a 750 kW electric skid for night shift—operators liked the silent start and near-zero on-site NOx.

- Resin plant: adopted a wet-back molten salt boiler for 480°C loops; reported ±2°C stability at reactors and 8–10% fuel savings after burner optimization.

Bottom line: shortlist two or three electric steam boiler manufacturers for precision steam, and keep a high‑heat alternative in your pocket when process temperatures or storage point you beyond steam’s comfort zone.

Authoritative references

- ASME Boiler & Pressure Vessel Code, Sections I/IX.

- EN 12952/12953 Water-tube and shell boiler standards.

- ISO 9001:2015 Quality management systems.

- UL 508A Industrial Control Panels.

- IEC 61508 Functional safety of E/E/PE systems.

- GB/T 16508 Shell Boilers (China National Standard).

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025