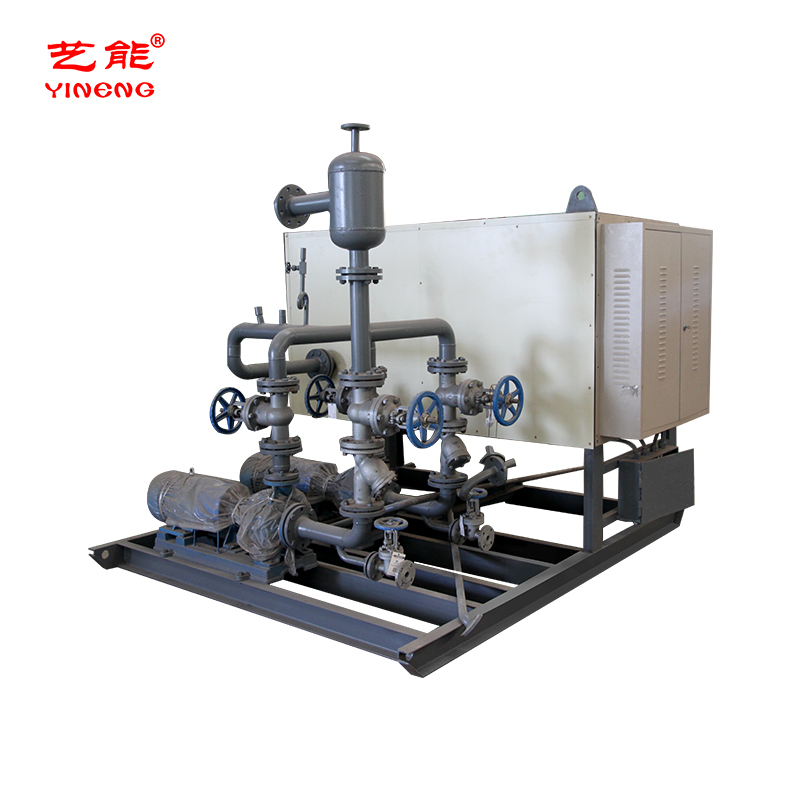

Electric Steam Boiler Manufacturers - Industrial & Efficient Solutions

The Evolving Landscape of Industrial Steam Generation: Focus on Electric Solutions

The industrial sector's reliance on efficient and sustainable steam generation is more critical than ever. As global energy policies shift towards decarbonization and operational efficiency becomes paramount, the demand for advanced heating solutions escalates. Among these, the role of electric steam boiler manufacturers is rapidly expanding, driven by their inherent cleanliness, precision control, and adaptability. These systems offer a compelling alternative to traditional fossil-fuel fired boilers, particularly in industries requiring stringent environmental compliance and superior process control.

Industry trends indicate a significant move towards electrification in process heating. Factors such as fluctuating fossil fuel prices, the push for reduced carbon emissions, and advancements in renewable energy integration make electric boilers a strategic investment. While the market for a gas steam boiler for sale remains robust, particularly where natural gas infrastructure is established and cost-effective, the scalability and zero-emission operation at the point of use for electric variants present undeniable long-term advantages. The integration of a sophisticated thermostat for steam boiler systems is also crucial across all boiler types, ensuring optimal energy utilization and precise temperature management for various industrial processes.

Beyond direct steam generation, related technologies like the steam boiler heat exchanger are vital components for enhancing overall system efficiency, recovering waste heat, and preheating feedwater, thereby further optimizing the energy consumption of these sophisticated systems. The landscape is dynamic, with innovation continually reshaping how industries generate and utilize steam.

The Manufacturing Process of Advanced Electric Steam Boilers

The production of high-performance electric steam boilers is a meticulous process demanding precision engineering, advanced materials, and rigorous quality control. Reputable electric steam boiler manufacturers adhere to stringent international standards to ensure reliability and safety. The core process flow typically involves several critical stages:

1. Material Selection & Preparation

High-grade boiler steel (e.g., SA-516 Grade 70 for pressure vessels, SA-192 for boiler tubes) is selected for its strength, corrosion resistance, and thermal properties. Materials undergo strict inspection for chemical composition and mechanical properties, ensuring compliance with standards like ASME Boiler and Pressure Vessel Code.

2. Component Fabrication

This stage involves precise cutting (laser or plasma), forming (rolling, bending), and welding of boiler shells, dished heads, and tube sheets. CNC machining ensures tight tolerances for tube holes and flange connections. Heating elements, often Incoloy or similar high-nickel alloys, are manufactured and tested separately.

3. Assembly & Welding

Key components are assembled. Automated welding techniques (e.g., TIG, MIG) are employed to ensure structural integrity and minimize defects. All critical welds are subjected to non-destructive testing (NDT) such as X-ray, ultrasonic, or magnetic particle inspection to meet ISO and ANSI standards.

4. Hydrostatic & Performance Testing

Completed pressure vessels undergo hydrostatic testing at 1.5 times the design pressure to verify leak integrity. Electrical components, control systems, and safety devices are rigorously tested for functionality and compliance. Efficiency and steam quality tests are also conducted under simulated operational conditions.

5. Insulation & Finishing

High-density thermal insulation (e.g., mineral wool, ceramic fiber) is applied to minimize heat loss, improving energy efficiency. External casings are fitted, and corrosion-resistant coatings are applied, enhancing the boiler's service life and aesthetic appeal.

The service life of a well-maintained industrial electric steam boiler can exceed 20 years, largely due to the high-quality materials and manufacturing precision. These boilers find extensive application across diverse sectors including petrochemicals (for process heating), metallurgy (for heat treatment and preheating), and water supply & drainage (for sterilization and hot water). Their key advantages include energy saving through precise control and minimal standby losses, and inherent corrosion resistance due to the absence of combustion byproducts, making them ideal for sensitive environments.

Technical Specifications and Performance Parameters

Understanding the technical parameters is crucial for selecting the right industrial steam boiler. Electric steam boiler manufacturers engineer their products for optimal performance, safety, and efficiency across a range of applications. Below is a representative table of specifications for a typical industrial electric steam boiler, demonstrating key performance indicators.

Electric Industrial Steam Boiler Specifications

| Parameter | Typical Range/Value | Unit |

|---|---|---|

| Rated Evaporation Capacity | 100 - 6000 | kg/h |

| Rated Working Pressure | 0.7 - 2.5 | MPa |

| Steam Temperature | 170 - 225 | °C |

| Rated Thermal Efficiency | >99 | % |

| Operating Voltage | 380V / 400V / 480V / 690V | AC, 3-Phase |

| Heating Element Material | Incoloy 800/840 | - |

| Control System | PLC with HMI | - |

| Safety Features | Over-pressure, Low water, Over-temp, Leakage protection | - |

The high thermal efficiency, often exceeding 99%, for electric steam boiler industrial applications is a direct result of their operational principle: nearly all electrical energy is converted into heat within the boiler vessel. This contrasts with combustion boilers, where significant heat loss occurs through exhaust gases. Furthermore, the precise digital control offered by modern electric boilers allows for rapid response to load changes and tight temperature regulation, crucial for sensitive industrial processes.

Application Scenarios and Technical Advantages

Electric steam boilers are highly versatile, serving a broad spectrum of industries where clean, reliable, and controllable steam is essential. Their operational profile makes them particularly advantageous in specific scenarios.

Key Application Industries:

- Pharmaceuticals & Biotech: Sterilization, humidification, and process heating where purity and absence of combustion byproducts are critical.

- Food & Beverage: Cooking, sterilization, pasteurization, and cleaning-in-place (CIP) systems requiring sanitary steam.

- Textiles: Dyeing, drying, and steaming processes that benefit from consistent steam quality.

- Hospitals & Healthcare: Sterilization of instruments, laundry, and humidification for patient comfort and infection control.

- Chemical Processing: Reactor heating, distillation, and heat transfer applications.

- Pulp & Paper: Process heating, drying, and conditioning.

- Manufacturing & Machining: Part cleaning, degreasing, and climate control in facilities.

Technical Advantages:

- High Efficiency & Precision: With near 100% thermal efficiency, electric boilers convert almost all input energy to steam. PLC-based controls, often integrated with a sophisticated thermostat for steam boiler, allow for precise temperature and pressure management, minimizing energy waste and ensuring product quality.

- Environmental Friendliness: No on-site emissions of NOx, SOx, or CO2, contributing to cleaner air and compliance with strict environmental regulations. This is a significant advantage over even the most efficient gas steam boiler for sale options in terms of local air quality.

- Compact Footprint & Easy Installation: Absence of fuel storage, chimneys, and complex combustion air systems results in smaller installation footprints and simplified installation, especially beneficial in urban or space-constrained facilities.

- Enhanced Safety: Without combustion, risks associated with fuel storage, flame supervision, and exhaust gas handling are eliminated. Multiple interlocks and safety features are standard.

- Low Maintenance: Fewer moving parts, no soot or ash accumulation, and reduced corrosion due to the absence of combustion byproducts lead to lower maintenance requirements and longer operational lifespans compared to fossil-fueled systems, including certain types of wood steam boiler systems.

- Quiet Operation: Electric boilers operate with minimal noise, making them suitable for environments where noise pollution is a concern.

- Rapid Start-up & Response: They can reach operating pressure quickly and respond swiftly to fluctuating steam demands, offering excellent load-following capabilities.

Vendor Comparison and Customized Solutions

Choosing the right partner among electric steam boiler manufacturers is a critical decision for any industrial operation. While many offer standard products, the ability to provide customized solutions and robust after-sales support often distinguishes leading vendors. Considerations extend beyond initial purchase price to include total cost of ownership (TCO), energy efficiency, system integration capabilities, and responsiveness of service.

Key Factors in Vendor Comparison:

| Feature/Criterion | Leading Manufacturer (e.g., YN Boilers) | Standard/Competitor |

|---|---|---|

| Thermal Efficiency | >99.5% | 98-99% |

| Modulation Ratio | 10:1 (or greater) for fine control | 5:1 (typical) |

| Control System | Advanced PLC with remote monitoring, IoT integration | Basic PLC with local HMI |

| Material Grade (Pressure Parts) | ASME SA-516 Grade 70 / EN 10028 P265GH | ASTM A36 equivalent |

| Certifications | ASME, CE, ISO 9001, PED | Local/Regional certifications |

| Customization Capabilities | Extensive, including pressure, capacity, voltage, footprint | Limited standard options |

| Warranty (Standard) | 2 years for parts, 10 years for pressure vessel | 1 year for parts |

Customized Solutions:

Leading electric steam boiler manufacturers recognize that off-the-shelf solutions rarely fit every unique industrial requirement. Customization is a key differentiator, allowing clients to optimize their heating systems for specific operational envelopes. This can include:

- Capacity & Pressure Adjustments: Tailoring steam output and operating pressure to match exact process demands, whether for a small, critical application or a large steam boiler industrial setup.

- Voltage & Power Configuration: Designing boilers to integrate seamlessly with existing electrical infrastructure, accommodating various global voltage standards.

- Footprint Optimization: Engineering compact designs for installations with limited space, or modular systems for future expansion. This is especially relevant when replacing older, larger systems like a weil mclain eg 40 steam boiler.

- Material Upgrades: Utilizing specialized alloys for enhanced corrosion resistance in aggressive environments or for ultra-pure steam applications.

- Control System Integration: Customizing PLC programming and HMI interfaces for integration with plant-wide DCS (Distributed Control Systems) or SCADA systems, enabling remote monitoring and advanced diagnostics.

- Ancillary Equipment: Supplying integrated solutions including feedwater systems, blowdown heat recovery, steam boiler heat exchanger units, and condensate return systems, all optimized for the electric boiler's performance. For specialized applications, even considerations for a water tube steam boiler design might be part of a custom solution.

Real-World Application Case Studies and Trust Elements

The practical deployment of electric steam boilers across various industries underscores their efficacy and the trust placed in leading electric steam boiler manufacturers. These case studies highlight tangible benefits and demonstrate adherence to the highest standards of Authoritativeness and Trustworthiness.

Case Study 1: Pharmaceutical Manufacturing Plant

- Challenge: An established pharmaceutical plant needed to upgrade its sterilization and humidification steam supply to meet stricter FDA cleanroom standards and reduce reliance on fossil fuels.

- Solution: Installation of two 1500 kg/h electric steam boilers, precisely sized for critical process loads. Integrated with existing facility management systems, enabling real-time monitoring and control.

- Results: Achieved zero on-site emissions, significant reduction in operating noise, and consistent supply of high-purity steam. The client reported a 15% reduction in overall energy costs due to higher efficiency and better load matching, coupled with seamless FDA audit compliance.

Case Study 2: Food Processing Facility Upgrade

- Challenge: A dairy processing plant required increased steam capacity for pasteurization and CIP, facing rising natural gas prices and a desire for a cleaner energy profile.

- Solution: Implementation of a modular electric boiler system, including a 3000 kg/h unit and a smaller 800 kg/h unit for fluctuating demands. The system incorporated an advanced steam boiler heat exchanger for condensate return preheating.

- Results: Enhanced operational flexibility and reduced CO2 footprint by 100% on-site. The client noted reduced maintenance expenditures and improved product consistency due to stable steam pressure.

Authoritativeness & Trustworthiness:

- Certifications: Reputable manufacturers hold international certifications such as ASME Boiler & Pressure Vessel Code stamps (e.g., "S," "U," "PP"), CE mark for European conformity, ISO 9001 for quality management, and PED (Pressure Equipment Directive) compliance.

- Industry Experience: Companies with decades of experience, having served hundreds or thousands of clients across various sectors, demonstrate deep expertise and reliability. Partner clients often include Fortune 500 companies and critical infrastructure providers.

- Testing & Data: All boilers undergo rigorous testing protocols including hydrostatic, non-destructive, and performance tests, with comprehensive data available for client review, ensuring transparency and verifiable product integrity.

- Quality Control: Adherence to strict internal quality control procedures at every stage, from material sourcing to final assembly and testing, often surpassing minimum regulatory requirements.

Frequently Asked Questions (FAQ)

Q1: What are the main advantages of an electric steam boiler over a traditional fuel-fired boiler?

A: Electric steam boilers offer superior thermal efficiency (typically >99%), zero on-site emissions, precise temperature and pressure control, quiet operation, and lower maintenance costs due to the absence of combustion components. They also require no fuel storage or chimney systems.

Q2: What is the typical lead time for an industrial electric steam boiler?

A: Lead times for industrial electric steam boilers can vary depending on customization requirements, capacity, and current production schedules. Typically, standard models can be fulfilled within 8-12 weeks, while highly customized solutions may require 12-20 weeks from order confirmation to shipment.

Q3: What kind of warranty do electric steam boiler manufacturers typically offer?

A: Most reputable manufacturers offer a standard warranty of 1-2 years on parts and components, and an extended warranty of 5-10 years on the pressure vessel (boiler shell), subject to terms and conditions regarding proper installation and maintenance. Specifics should always be confirmed with the vendor.

Q4: How important is water treatment for electric boilers?

A: Water treatment is extremely important for electric boilers, just as it is for any steam boiler industrial application. Proper feedwater quality prevents scaling on heating elements, which significantly impacts efficiency and boiler lifespan. Demineralization or reverse osmosis is often recommended to maintain optimal performance and reduce blowdown requirements.

Q5: What after-sales support can I expect?

A: Leading electric steam boiler manufacturers provide comprehensive after-sales support, including installation supervision, commissioning services, operator training, preventive maintenance programs, and readily available spare parts. 24/7 technical support, remote diagnostics, and on-site service by certified technicians are also common offerings to ensure continuous operation.

Conclusion: The Future of Industrial Steam

The trajectory of industrial steam generation is clearly shifting towards more sustainable, efficient, and technologically advanced solutions. Electric steam boiler manufacturers are at the forefront of this transformation, offering systems that not only meet stringent environmental regulations but also provide significant operational and economic advantages. As industries continue to seek pathways to decarbonize their operations and optimize resource utilization, the role of electric boilers, supported by robust after-sales service and customizable engineering, will only grow in prominence. Investing in these modern systems represents a forward-thinking approach to industrial heating, ensuring long-term reliability and environmental stewardship.

References:

- International Energy Agency. (2023). Industry Energy Technology Perspectives.

- American Society of Mechanical Engineers (ASME). (2021). Boiler and Pressure Vessel Code.

- U.S. Department of Energy. (2022). Steam Systems – An Opportunity for Energy Efficiency.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality Management Systems – Requirements.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025