Electric Steam Boiler Manufacturers: Efficient, Reliable?

electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of boilers and auxiliary equipment. This article explores how Hebei Yineng Boiler Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler Overview

- Benefits & Use Cases of electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler in Manufacturing of boilers and auxiliary equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler from Hebei Yineng Boiler Co., Ltd

electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler Overview

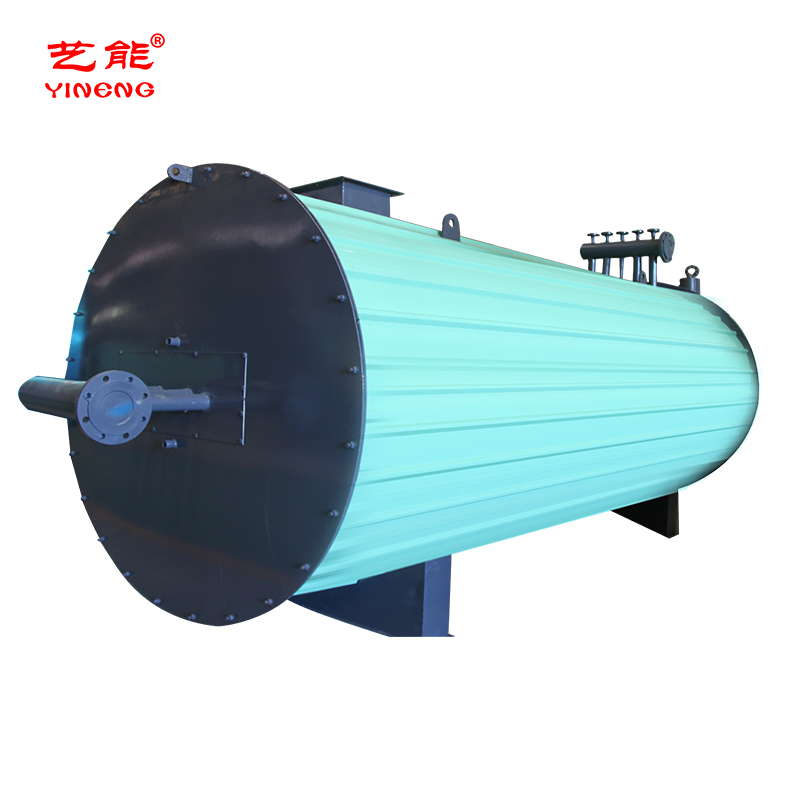

Across the steam generation ecosystem—spanning electric steam boiler manufacturers, classic water tube steam boiler designs, compact units such as the Weil-McLain EG 40 steam boiler, and biomass-based wood steam boiler solutions—B2B decision makers are seeking higher thermal efficiency and safer, more controllable heat sources. Hebei Yineng Boiler Co., Ltd addresses these priorities with its gas/oil-fired molten salt boiler, a high-temperature thermal solution that integrates seamlessly with a steam boiler heat exchanger to produce stable, on-demand process steam for steam boiler industrial applications.

By circulating molten salt as the heat transfer medium, the system achieves uniform heat distribution and high outlet temperatures suitable for indirect steam generation and complex process heating. Advanced control logic—functionally akin to a thermostat for steam boiler packages—enables precise temperature management, smooth startup, and load-following performance. As a seasoned manufacturer in the Manufacturing of boilers and auxiliary equipment segment, Hebei Yineng Boiler Co., Ltd delivers engineered systems that help facilities transition from direct-fired steam to safer, indirect configurations without sacrificing throughput or quality.

Benefits & Use Cases of electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler in Manufacturing of boilers and auxiliary equipment

In production environments that rely on consistent steam—textiles, chemicals, food and beverage, building materials, and pharmaceutical manufacturing—the combination of a molten salt heater plus a steam boiler heat exchanger can outperform direct-fired steam packages. Compared with a gas steam boiler for sale deployed as a standalone, indirect generation isolates the flame from the steam circuit, reducing scaling, corrosion risk, and thermal shocks common to water tube steam boiler systems under rapid cycling.

Key advantages include high thermal stability, tight temperature control via integrated “thermostat for steam boiler” style automation, reduced water-side maintenance, and improved safety. For operations considering alternatives from electric steam boiler manufacturers or biomass-fueled wood steam boiler systems, Hebei Yineng Boiler Co., Ltd can configure hybrid solutions and recovery schemes to meet energy, emissions, and uptime targets. Their engineering expertise in steam boiler industrial projects ensures fit-for-purpose sizing, compliance with local codes, and turnkey commissioning support—accelerating time to value and de-risking upgrades or plant expansions.

Cost, Maintenance & User Experience

Total cost of ownership is driven by fuel efficiency, maintenance intervals, and unplanned downtime. Molten salt systems paired with a steam boiler heat exchanger minimize water-side fouling, decreasing blowdown frequency and chemical treatment costs compared with many direct-fired gas steam boiler for sale alternatives. Durable construction and accessible service points help extend lifecycle, while digital controls streamline diagnostics and trending—delivering a practical path to higher OEE.

Feedback from industrial users highlights quicker thermal response, steadier steam quality at varying loads, and lower intervention rates versus traditional water tube steam boiler setups in tough duty cycles. Facilities that previously ran small cast-iron units—like a Weil-McLain EG 40 steam boiler—report smoother scaling to higher capacities with Hebei Yineng Boiler Co., Ltd’s engineered solutions. When benchmarked against electric steam boiler manufacturers for similar steam outputs, customers often see favorable ROI due to fuel flexibility and optimized heat transfer, especially in regions with volatile electricity pricing.

Sustainability & Market Trends in manufacturing

Global manufacturing is moving toward higher efficiency, fuel flexibility, and lower emissions. Indirect steam generation with molten salt enables integration with waste-heat recovery, solar thermal, or future-ready low-carbon fuels—supporting progressive compliance pathways and corporate ESG commitments. Compared with conventional wood steam boiler options, advanced burners and optimized heat exchange can yield cleaner combustion profiles and more predictable emissions control.

Market trends also favor smart instrumentation—akin to a thermostat for steam boiler packages—combined with data logging and remote monitoring. Hebei Yineng Boiler Co., Ltd incorporates intelligent controls and safety interlocks to align with tightening standards and digital plant initiatives. Whether a site is evaluating an immediate gas steam boiler for sale, comparing water tube steam boiler retrofits, or shortlisting electric steam boiler manufacturers for electrification pilots, Yineng’s molten salt platform offers a versatile, future-forward core that can be integrated now and decarbonized progressively over time.

Conclusion on electric steam boiler manufacturers,gas steam boiler for sale,steam boiler heat exchanger,steam boiler industrial,thermostat for steam boiler,water tube steam boiler,weil mclain eg 40 steam boiler,wood steam boiler from Hebei Yineng Boiler Co., Ltd

From electric steam boiler manufacturers to water tube and wood steam boiler alternatives, today’s plants need safer, cleaner, and more controllable thermal solutions. Hebei Yineng Boiler Co., Ltd’s gas/oil-fired molten salt boiler pairs seamlessly with a steam boiler heat exchanger to deliver reliable steam, strong efficiency, and lower maintenance in steam boiler industrial operations. Partner with a manufacturer that understands your process, compliance needs, and growth plans.

Contact us: email: leesonzhou@aliyun.com

Visit our website: https://www.ynboilers.com

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025