Electric Steam Boiler Manufacturers: Efficient & Clean?

Electric Steam Boiler Manufacturers in 2025: Field Notes from the Boiler Room

If you’re sizing up electric steam boiler manufacturers right now, you’re not alone; the shift to low-carbon heat is very real. Utilities are rolling out cheaper off-peak tariffs, and—surprisingly—controls have caught up, so ramp rates and turndown aren’t the worry they used to be. I’ve toured a few plants this year; the vibe is pragmatic: electrify where it fits, hybridize where it doesn’t.

What’s moving the market

- Electrification incentives + carbon accounting pressure.

- Better element metallurgy (Incoloy 800/840) and modular skids.

- Smart controls with demand response and power-limiting modes.

Quick vendor snapshot (global players)

| Vendor | HQ | Typical kW Range | Certifications (examples) | Notes |

|---|---|---|---|---|

| Cleaver-Brooks | USA | 15–1,800 kW | ASME, UL 834, cUL | Robust service network; school/hospital favorite. |

| Fulton | USA/UK | 20–960 kW | ASME, CE (PED) | Compact vertical units; quick lead times. |

| Chromalox | USA | 18–6,000 kW | UL 508A, UL 834, ISO 9001 | Strong on process integration and controls. |

Reference spec (typical electric steam boiler)

| Model | E-500 (≈500 kW) |

| Steam Output | ≈760 kg/h @10 bar (real-world use may vary) |

| Efficiency (element-to-steam) | 98–99% |

| Elements | Incoloy 800/840, replaceable banks |

| Controls | SCR with power limiting, MODBUS/ BACnet |

| Standards | ASME BPVC I, UL 834, CE (PED) |

Factory test data: hydrostatic at 1.5× MAWP, insulation heat loss <1%/hr, dryness fraction ≥0.95, leak test per ASME IX procedures.

How they’re built (short version)

- Materials: pressure shell SA-516 Gr.70 or 304/316L; elements Incoloy; gaskets EPDM/graphite.

- Methods: CNC rolling, TIG/SMAW welds, PWHT where required, RT/UT and dye-penetrant on critical seams.

- Testing: hydro 1.5× MAWP, insulation verification, control FAT, safety valve set/test per NBIC.

- Service life: 10–15 years; elements 3–7 years depending on TDS/chemistry (many customers say softening makes or breaks it).

Where electrics shine (and where they don’t)

Hospitals, pharma CIP/SIP, labs, food blanching, small breweries—clean, quiet, easy permitting. However, for high-temperature thermal loops (say 350–480°C) or fuel-flexible sites, I often see a dual-path: electric steam for sanitary loads and a fired salt system for process heat.

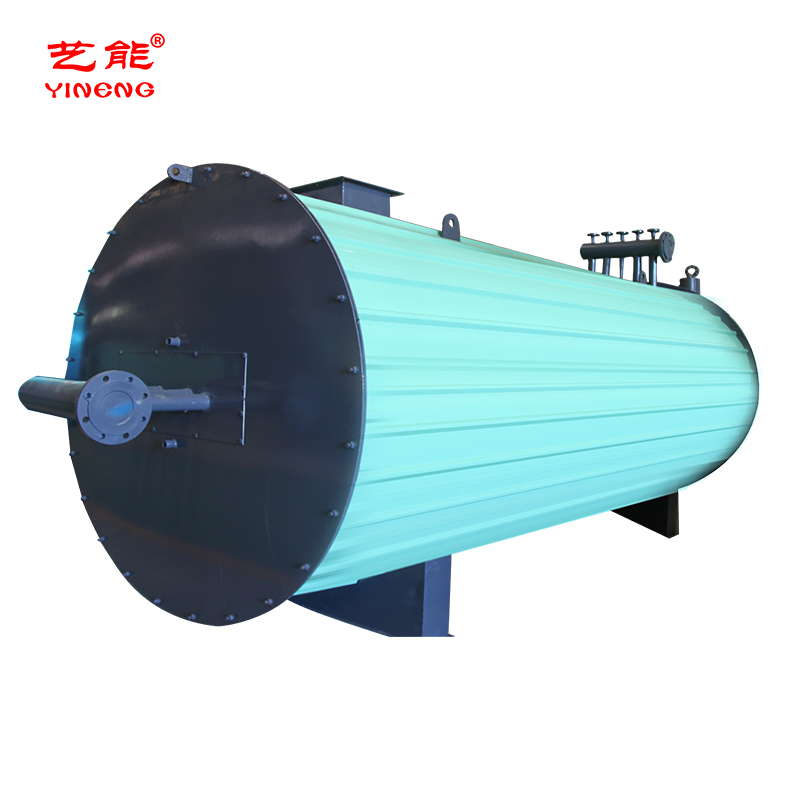

Related option: Gas oil fired molten salt boiler

From Wuqiao, Hebei, China, this unit uses a wet-back internal combustion two-pass structure—compact and efficient—which pairs well with thermal oil/salt circuits when electrifying everything is unrealistic. To be honest, it’s a practical bridge technology.

- High transfer efficiency, stable salt temperature control.

- Integrates with plate heat exchangers or jacketed reactors.

- Origin: Wuqiao, Hebei, China.

Selection tips (my cheat sheet)

- Power quality: confirm transformer capacity and peak kW limits.

- Water chemistry: TDS < 2,000 ppm; consider RO + softener; install blowdown controls.

- Controls: demand-response ready; staged elements reduce harmonics and inrush.

- Documentation: ASME data report, UL 834 label, PED/CE if exporting.

End-user feedback? It seems that maintenance drops sharply—no burners, no stacks—though operators still want simple HMIs and fast spares. When comparing electric steam boiler manufacturers, I always ask for a parts list with lead times, not just glossy brochures.

Mini case study

A mid-size sauce plant replaced a 300 kW gas unit with a 450 kW electric boiler for CIP while keeping a fired molten-salt system for kettles. Result: ≈21% energy cost reduction using off-peak, steam quality improved, and zero NOx permits. Not glamorous, but it worked.

Standards and proofs

Look for ASME BPVC I stamps, UL 834 labels, CE (PED) CE-marking, ISO 9001 QMS, and test records (hydrostatic, insulation heat loss, and safety valve certifications). That’s the boring paperwork that prevents exciting failures.

Citations

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025