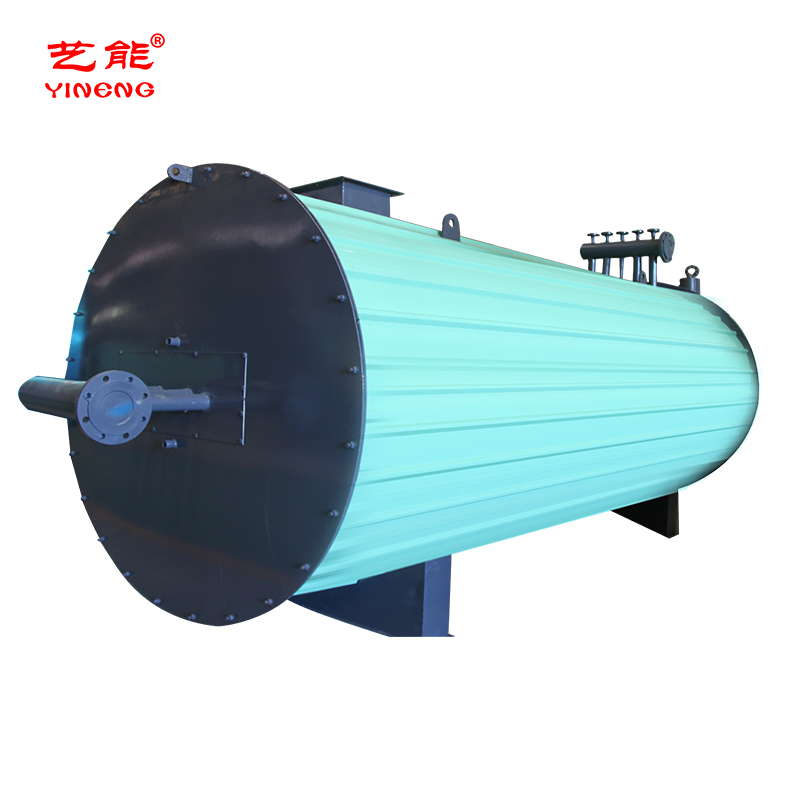

Electric Steam Boiler Manufacturers | High-Efficiency Industrial Solutions

Understanding the Landscape of Electric Steam Boiler Manufacturing

In the modern industrial landscape, the demand for clean, efficient, and reliable steam generation solutions is paramount. This drives innovation among leading electric steam boiler manufacturers. Unlike traditional fossil fuel boilers, electric variants offer significant advantages in terms of environmental impact, operational simplicity, and energy efficiency, particularly when integrated with renewable energy sources. These systems are becoming indispensable across various sectors, from food processing and pharmaceuticals to chemical plants and textiles, providing precise temperature and pressure control without the complexities of fuel combustion or emissions management.

The shift towards electrification in industrial heating is not merely an environmental mandate but a strategic business decision, offering operational cost savings, enhanced safety, and greater flexibility. As such, understanding the capabilities and offerings of top-tier electric steam boiler manufacturers is crucial for businesses aiming to optimize their thermal energy infrastructure. This article delves into the technical intricacies, market dynamics, and operational benefits associated with advanced electric steam boiler systems, offering a comprehensive guide for B2B decision-makers.

Current Industry Trends and Market Evolution

The industrial steam boiler market is experiencing a significant paradigm shift driven by stringent environmental regulations, escalating fuel costs for traditional systems, and a global push towards decarbonization. This has propelled electric steam boilers to the forefront, with their market share steadily increasing. Key trends include:

- Integration with Renewable Energy: A growing number of industrial facilities are coupling electric boilers with renewable energy sources (solar, wind) to achieve carbon-neutral operations, enhancing their sustainability profiles.

- Smart Control Systems: Advanced PLCs and IoT-enabled control systems are standard, allowing for remote monitoring, predictive maintenance, and optimized energy consumption. These systems often feature sophisticated algorithms to manage load fluctuations and integrate seamlessly with plant-wide automation.

- Compact Designs: Space optimization is a critical concern, leading manufacturers to develop more compact, modular designs that simplify installation and reduce footprint, particularly beneficial for facilities with limited space.

- Enhanced Safety Protocols: With the absence of combustion and fuel storage, electric boilers inherently offer safer operation. Manufacturers are further enhancing this with multiple layers of redundant safety controls and pressure vessel designs adhering to ASME and PED standards.

- Focus on Water Treatment: Given the sensitivity of electric heating elements to scale and corrosion, innovations in integrated water treatment systems (e.g., reverse osmosis, dealkalization) are becoming a standard offering. This prolongs service life and maintains efficiency.

While traditional options like a gas steam boiler for sale or even a wood steam boiler still exist, the increasing preference for cleaner energy and operational simplicity is driving demand towards electric solutions, and manufacturers are responding with more sophisticated and efficient models.

Detailed Manufacturing Process Flow of Electric Steam Boilers

The production of industrial electric steam boilers is a highly specialized process, demanding precision engineering, robust material selection, and rigorous quality control. Reputable electric steam boiler manufacturers follow a multi-stage process to ensure product reliability and compliance with international standards.

Process Flow Schematic:

1. Design & Engineering (CAD/CAE)

2. Material Sourcing & Preparation

(High-grade steel plates, heating elements, control components)

3. Pressure Vessel Fabrication

(Cutting, Bending, Welding - ASME/PED certified welders)

4. Heating Element Integration

(Precise installation of immersion or electrode type elements)

5. Control System Assembly

(PLC, HMI, safety sensors, electrical wiring)

6. Insulation & Jacketing

(Thermal insulation for efficiency, protective outer casing)

7. Hydrostatic & NDT Testing

(Pressure vessel integrity, weld quality - ISO 9001, ANSI B31.1 standards)

8. Performance Testing & Calibration

(Efficiency, pressure, temperature control, safety interlocks)

9. Surface Treatment & Painting

(Corrosion protection, aesthetic finish)

10. Final Inspection & Documentation

(Quality assurance, compliance certificates)

11. Packaging & Shipping

Key Manufacturing Stages & Materials:

- Materials: High-quality carbon steel (e.g., SA-516 Grade 70) for pressure vessels, stainless steel (e.g., SS316L) for heating elements and wetted parts in specific applications requiring corrosion resistance. Electrical components are sourced from certified suppliers to meet NEMA or IP ratings.

- Manufacturing Processes:

- Casting/Forging: Used for specialized fittings, flanges, and valve bodies to ensure high pressure integrity.

- CNC Machining: Precision machining of component interfaces, such as heating element ports and instrument connections, guarantees tight tolerances and leak-free operation.

- Advanced Welding: Techniques like submerged arc welding (SAW) and gas tungsten arc welding (GTAW) are employed by certified welders (e.g., per ASME Section IX) to ensure robust and durable pressure boundary integrity.

- Testing Standards: All boilers undergo rigorous testing, including hydrostatic pressure tests (typically 1.5 times design pressure) and non-destructive testing (NDT) such as ultrasonic testing (UT) or radiographic testing (RT) on critical welds, adhering to international standards like ISO 9001, ASME Boiler and Pressure Vessel Code, and European PED.

- Service Life: With proper maintenance and water treatment, an industrial electric steam boiler is designed for a service life of 20-30 years, often exceeding that of combustion-based systems due to fewer moving parts and less corrosive environments.

Technical Specifications and Parameters

The performance of an electric steam boiler is defined by its core technical specifications. These parameters are crucial for engineers and procurement specialists to ensure the boiler meets specific application requirements. Understanding aspects like power rating, steam output, and operating pressure is vital for system integration and efficiency.

Typical Electric Steam Boiler Specifications:

| Parameter | Range / Typical Value | Units |

|---|---|---|

| Steam Output Capacity | 100 to 10,000+ | kg/h (or lbs/hr) |

| Power Rating | 50 to 8,000+ | kW |

| Operating Pressure | Up to 20 | bar (or 290 psi) |

| Steam Quality | 99% Dry Saturated Steam | % |

| Efficiency | 98% to 99.5% | % |

| Voltage | 208V to 600V (3-phase) | VAC |

| Temperature Control | PID or PLC based, ±1°C | Precision |

| Footprint (for 500 kg/h) | Approx. 1.5m x 1.0m x 2.0m | (L x W x H) |

A crucial component for maintaining optimal performance is the thermostat for steam boiler systems. Modern electric boilers integrate highly sensitive temperature control systems that work in conjunction with pressure sensors to regulate steam output precisely. The design often involves a water tube steam boiler configuration for high-pressure applications, offering rapid steam generation and superior response to load changes compared to fire tube designs.

Application Scenarios and Target Industries

Electric steam boilers are versatile thermal energy sources, finding widespread application across a multitude of industrial sectors where clean, reliable, and controllable steam is essential. Their advantages become particularly pronounced in sensitive environments or where emissions are strictly regulated.

Target Industries:

- Petrochemical & Chemical Processing: For heating reactors, distillation columns, and sterilizing equipment. The absence of an open flame is a significant safety advantage in hazardous areas.

- Pharmaceutical & Biotech: Sterilization of equipment (autoclaves), humidification in cleanrooms, and process heating requiring ultra-pure steam. Regulatory compliance (e.g., FDA standards) often favors electric systems due to their precise control and lack of combustion byproducts.

- Food & Beverage: Cooking, pasteurization, sterilization, and CIP (Clean-in-Place) systems. Ensures product quality and safety by providing clean steam.

- Healthcare (Hospitals): Sterilization, laundry, and humidification for HVAC systems. Reliability and hygiene are paramount.

- Textiles & Apparel: Dyeing, finishing, and steaming processes requiring consistent temperature and pressure.

- Water Supply & Drainage: Heating for sludge treatment, digesters, and other water purification processes.

- Commercial Buildings: Humidification, space heating, and hot water generation for large complexes.

Advantages in Typical Application Scenarios:

- Energy Saving: Near 100% efficiency in converting electrical energy to heat, minimizing standby losses. Coupled with rapid heat-up times, this translates to significant energy savings, especially in intermittent operation.

- Corrosion Resistance: When specified with stainless steel wetted parts, electric boilers offer superior resistance to corrosion, particularly important in applications using aggressive feedwater or producing ultra-pure steam. This extends the lifespan of the steam boiler heat exchanger components.

- Environmental Benefits: Zero on-site emissions of NOx, SOx, or CO2, contributing to a reduced carbon footprint and compliance with environmental regulations.

- Compact Footprint: Absence of fuel storage tanks, flues, and complex combustion systems results in a smaller installation footprint, freeing up valuable floor space.

- Ease of Maintenance: Fewer moving parts and no combustion-related maintenance (e.g., burner cleaning, soot removal) reduce downtime and labor costs, making a steam boiler industrial operation more streamlined.

Vendor Comparison: Evaluating Top Electric Steam Boiler Manufacturers

Selecting the right electric steam boiler manufacturers involves a thorough evaluation of various factors, including product quality, technological innovation, after-sales support, and adherence to international standards. While many manufacturers offer competitive solutions, key differentiators can impact long-term operational costs and reliability.

Comparison of Key Features Among Leading Manufacturers:

| Feature | Manufacturer A (e.g., Focus on Compact Design) | Manufacturer B (e.g., Focus on High Capacity) | Manufacturer C (e.g., Focus on Customization) |

|---|---|---|---|

| Steam Capacity Range | 50 - 2,000 kg/h | 1,000 - 10,000 kg/h | 100 - 8,000 kg/h |

| Operating Pressure | Up to 10 bar | Up to 20 bar | Up to 16 bar |

| Efficiency (Electrical to Steam) | 99% | 99.5% | 98-99% |

| Control System | Basic PLC with HMI | Advanced PLC with IoT integration | Modular PLC, customizable |

| Certifications | ASME, CE | ASME, PED, UL, CSA | ASME, CE, various local |

| Special Features | Quick Start, Small Footprint | Multi-boiler Sequencing, High Purity Steam options | Explosion-proof variants, Marine certified |

When evaluating, consider not just the listed specifications but also the vendor's experience with specific applications. Some manufacturers might specialize in certain boiler types, such as a robust weil mclain eg 40 steam boiler alternative in electric form, or highly customized solutions tailored for niche industries. The choice also depends on whether the requirement is for a new installation or replacing an existing steam boiler industrial unit.

Customized Solutions and Application Case Studies

Many industrial processes have unique requirements that cannot be met by off-the-shelf solutions. Leading electric steam boiler manufacturers excel in providing customized systems tailored to precise operational needs, integrating specific control functionalities, material specifications, and footprint constraints.

Customization Options:

- Pressure and Temperature Variation: Custom designs for ultra-high pressure or specific superheated steam applications.

- Material Selection: Use of exotic alloys for highly corrosive environments or sanitary-grade stainless steel for pharmaceutical applications.

- Control Integration: Seamless integration with existing DCS (Distributed Control Systems), SCADA, or building management systems (BMS).

- Skid-Mounted Solutions: Compact, pre-piped, and pre-wired boiler rooms or modules for rapid deployment and minimal on-site installation.

- Energy Management: Integration with demand-side management programs, load shedding capabilities, or renewable energy grids.

Application Case Study: Pharmaceutical Sterilization Plant

A major pharmaceutical manufacturer required a highly reliable and sterile steam source for their new autoclave sterilization lines. Their existing system relied on a traditional boiler, which posed challenges with emissions and fuel storage in their sensitive facility. They partnered with a leading electric steam boiler manufacturer.

- Challenge: Need for ultra-pure steam, zero emissions on-site, rapid steam on demand, and seamless integration with existing plant automation.

- Solution: Installation of two redundant 1,500 kg/h electric steam boilers featuring stainless steel pressure vessels and internal components, combined with an advanced RO (Reverse Osmosis) water treatment system. The boilers were supplied with a custom PLC integrating with the plant's DCS for centralized control and monitoring.

- Outcome: Achieved consistent 99.8% dry saturated steam quality, exceeding USP standards for pharmaceutical use. Reduced operational costs by 18% due to higher efficiency and lower maintenance. Eliminated all on-site emissions, improving air quality and regulatory compliance. Customer feedback highlighted the system's "unparalleled reliability and ease of operation," directly contributing to increased production uptime.

Ensuring Trustworthiness and Comprehensive Support

Trustworthiness in B2B transactions, particularly for critical infrastructure like industrial boilers, is built on transparency, robust support, and clear commitments. Reputable electric steam boiler manufacturers prioritize customer satisfaction through comprehensive support services.

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for an electric steam boiler?

A: Lead times vary based on capacity and customization. Standard models typically have a lead time of 8-12 weeks from order confirmation. Highly customized solutions may extend to 16-24 weeks. Expedited options might be available upon request.

Q: What warranty coverage is offered?

A: Standard warranty includes 12 months for parts and labor from commissioning or 18 months from shipment, whichever comes first. Pressure vessel warranties typically extend for 5 years against manufacturing defects. Extended warranty programs are also available.

Q: What kind of after-sales support is provided?

A: Comprehensive after-sales support includes 24/7 technical assistance, on-site commissioning services, operator training, preventive maintenance contracts, and readily available spare parts. We maintain a global network of certified service technicians to ensure prompt support.

Q: Can your electric boilers integrate with our existing building management system?

A: Yes, our advanced PLC-based control systems are designed for seamless integration with various BMS and SCADA platforms using standard communication protocols like Modbus TCP/IP, Ethernet/IP, and Profinet. Custom integration solutions are also available.

Lead Time and Fulfillment:

Our manufacturing facilities are optimized for efficient production, adhering to lean principles to minimize lead times without compromising quality. We employ robust supply chain management to ensure timely sourcing of high-quality components. Fulfillment includes comprehensive logistics planning, from crating and secure shipment to on-site delivery coordination, ensuring your boiler arrives safely and on schedule.

Warranty and Customer Support:

Our commitment to quality is underscored by industry-leading warranties and a dedicated customer support team. From initial consultation and system design to installation, commissioning, and ongoing maintenance, we provide end-to-end support. Our engineers are available for troubleshooting, technical advice, and performance optimization, ensuring the longevity and optimal operation of your steam boiler industrial system.

Conclusion

The landscape for industrial steam generation is rapidly evolving, with electric steam boiler manufacturers at the forefront of innovation. Their commitment to efficiency, environmental stewardship, and advanced technical features offers compelling advantages over conventional systems. For businesses seeking to modernize their thermal energy infrastructure, investing in a high-quality electric steam boiler represents a strategic move towards sustainable, cost-effective, and reliable operations. By understanding the manufacturing processes, technical specifications, and comprehensive support offered by leading vendors, decision-makers can confidently select solutions that drive long-term value and operational excellence.

References

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

- International Organization for Standardization (ISO) 9001:2015 - Quality Management Systems.

- European Pressure Equipment Directive (PED) 2014/68/EU.

- U.S. Department of Energy – Industrial Technologies Program, Steam Best Practices.

- Journal of Cleaner Production, Elsevier.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025