Jan . 29, 2025 01:56

Back to list

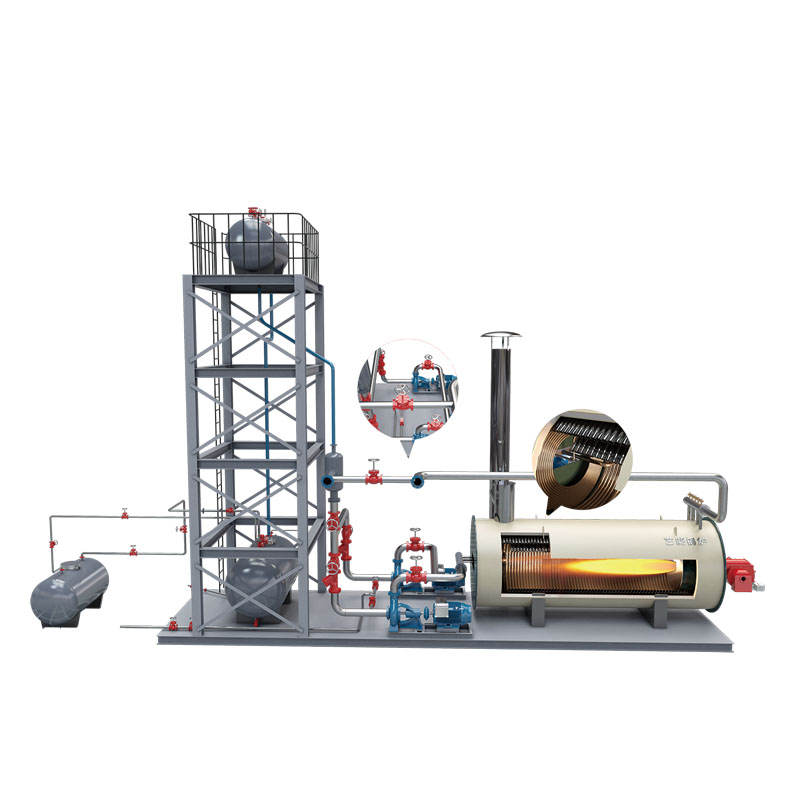

high efficiency gas fired steam boiler

In the rapidly evolving landscape of energy solutions, the introduction of high efficiency gas fired steam boilers represents a significant advancement in thermal energy generation. These boilers are lauded for their remarkable ability to convert gas into steam with unprecedented efficiency, thereby catering to the increasing demands for sustainable industrial practices.

The authority of high efficiency gas fired steam boilers is undisputed in regulatory circles, with numerous industry standards underscoring their performance metrics. Organizations such as the American Society of Mechanical Engineers (ASME) and the U.S. Department of Energy have established rigorous criteria that these systems consistently surpass, reinforcing their reputation as a benchmark for thermal energy production. Trustworthiness in the context of high efficiency boilers is built on years of consistent performance and the endorsement of satisfied customers across various industries. Manufacturers of these systems conduct extensive testing and certification processes to guarantee reliability and safety. This continuous dedication to quality assuages any concerns potential buyers may have, reassuring them of a dependable operational lifespan. As the global marketplace becomes increasingly concerned with sustainability, the adoption of high efficiency gas fired steam boilers is set to rise. These systems not only align with the green energy goals of numerous organizations but also serve as a catalyst for industrial innovation. Companies that harness this technology gain a competitive edge, combining sustainability with profitability. In summary, high efficiency gas fired steam boilers distinguish themselves through superior energy conversion, cost savings, and eco-friendly operations. They embody a synergy of cutting-edge technology and practical application, resonating well with sustainability-driven industries. The trust and authority they command ensure that they remain a crucial component in the toolkit of modern industrial operations. For businesses looking to future-proof their thermal energy solutions, these boilers represent a sound investment into a more efficient and environmentally conscious future.

The authority of high efficiency gas fired steam boilers is undisputed in regulatory circles, with numerous industry standards underscoring their performance metrics. Organizations such as the American Society of Mechanical Engineers (ASME) and the U.S. Department of Energy have established rigorous criteria that these systems consistently surpass, reinforcing their reputation as a benchmark for thermal energy production. Trustworthiness in the context of high efficiency boilers is built on years of consistent performance and the endorsement of satisfied customers across various industries. Manufacturers of these systems conduct extensive testing and certification processes to guarantee reliability and safety. This continuous dedication to quality assuages any concerns potential buyers may have, reassuring them of a dependable operational lifespan. As the global marketplace becomes increasingly concerned with sustainability, the adoption of high efficiency gas fired steam boilers is set to rise. These systems not only align with the green energy goals of numerous organizations but also serve as a catalyst for industrial innovation. Companies that harness this technology gain a competitive edge, combining sustainability with profitability. In summary, high efficiency gas fired steam boilers distinguish themselves through superior energy conversion, cost savings, and eco-friendly operations. They embody a synergy of cutting-edge technology and practical application, resonating well with sustainability-driven industries. The trust and authority they command ensure that they remain a crucial component in the toolkit of modern industrial operations. For businesses looking to future-proof their thermal energy solutions, these boilers represent a sound investment into a more efficient and environmentally conscious future.

Latest news

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025