Industrial boiler-What Are Different Types Of Industrial Boilers?

What Are Different Types Of Industrial Boilers?

Abstract

What Are Different Types Of Industrial Boilers-An industrial boiler is a device that generates steam or heats water and is widely used in the production process of various industries. As industries diversify their operations, so do their energy needs. Boilers are used as a means of production, and as technology advances, newer and more efficient models are constantly being developed.

The working principle of an industrial boiler is based on the principle of energy conversion. It provides thermal energy through the use of fuels (e.g. coal, oil, natural gas, biomass, etc.) to heat the medium to a high temperature and pressure state to produce steam or hot water. The steam or hot water is transported through pipes to the equipment that needs heat energy, achieving the transfer and use of energy.

- Industrial boilers are widely used in electric power, petrochemical, food processing, pharmaceutical, textile, printing and dyeing industries.

- In power plants, industrial boilers generate high-temperature, high-pressure steam to drive turbines to generate electricity.

- In petrochemical and chemical plants, industrial boilers provide heating and thermal energy to drive various reactions and processing operations.

- In food processing plants, industrial boilers are used for baking, sterilising, boiling and other processes.

- In pharmaceutical plants, they provide clean steam to meet the requirements of pharmaceutical processes.

- textile and dyeing industries, industrial boilers provide hot water or steam for dyeing, printing, drying and other processes

Types of Industrial Boilers

Based on different fuels and working principles, industrial boilers can be classified into various types, each with specific advantages and scope of application.EPCB, as a professional boiler manufacturer and supplier, offers a wide range of industrial boilers to meet the needs of customers in different fields.EPCB's boiler types include hot-water boiler, coal-fired boiler, oil & gas boiler, biomass-fired boiler, and electric boiler.

Hot Water Boiler

EPCB hot water boilers use the combustion of fuel or other energy sources to produce high temperature flue gases, and through the heat exchange between the flue gases and water, the water is heated to the required temperature to provide hot water supply. The process is realised through key components such as combustion system, flue system and water circulation system.

EPCB hot water boiler boilers are widely used in hotels, schools, hospitals and factories. In these places, EPCB hot water boiler can provide a reliable solution for heating, bathing, washing and other hot water needs. Its high efficiency and energy saving features make it an ideal choice for reducing energy consumption and lowering operating costs.

Coal-Fired Boilers

The EPCB coal-fired boiler is a traditional type of industrial boiler that burns coal to generate heat to meet the demand for hot water or steam in industrial production. It has the advantages of extensive fuel resources and relatively low cost. However, as its exhaust gas emissions contain a large number of pollutants, the environmental performance of coal-fired boilers needs to be improved by advanced combustion control and pollutant purification equipment.

EPCB coal-fired boilers adopt advanced combustion control technology and flue gas purification equipment, which improves combustion efficiency, reduces the emission level of coal-fired boilers, reduces the impact on the environment, and meets the demand for heat energy in most industrial production processes.

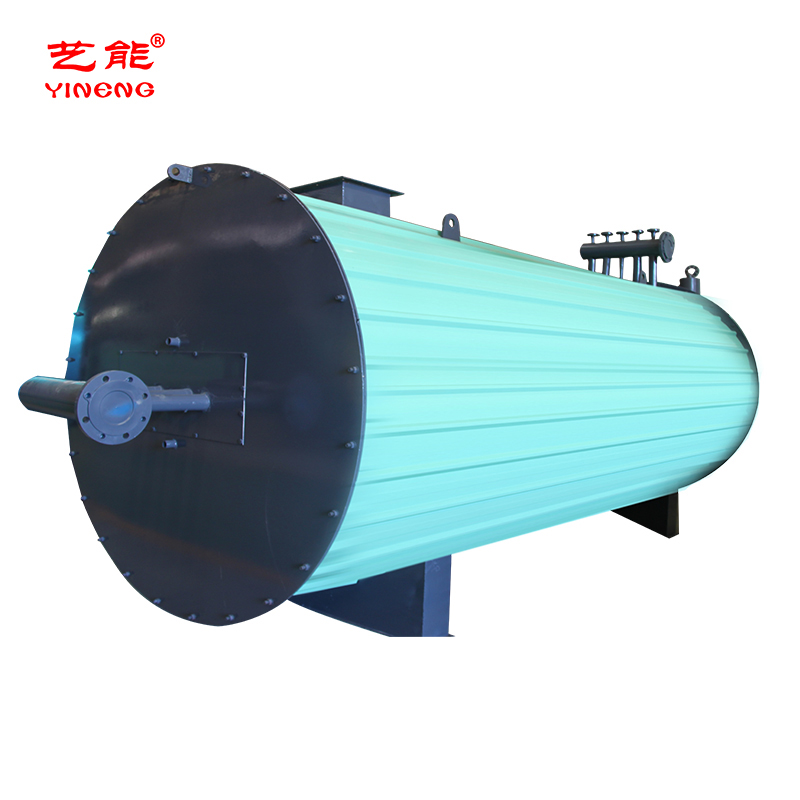

Oil(Gas) Fired Boiler

The EPCB gas fired boiler is a type of boiler that uses liquid fuel (such as heavy oil, light oil) or natural gas for combustion to produce heat energy. It is widely used in industrial production, especially in processes requiring high temperatures and pressures.The EPCB oil-fired gas boiler adopts the fourth generation of advanced wet-back three-way structure, featuring efficient and stable operation and fast steam generation, providing the ultimate solution for industrial production, heating and hot water supply.

Biomass-Fired Boiler

The EPCB biomass boilers is boiler that burn biomass fuels (e.g. wood chips, straw, wheat ears, etc.). They are usually divided into fixed grate biomass boilers, chain grate biomass boilers and reciprocating grate biomass boilers according to the different chain grates. The biomass-fired boiler is a renewable energy utilisation with the advantages of environmental protection and sustainability. Biomass boilers are widely used in agriculture, forestry and other fields, and their application in industrial production is gradually increasing.

Electric Boiler

The EPCB electric boiler is a type of boiler that converts electricity into heat energy. Unlike traditional gas or oil boilers, electric boilers do not require fuel storage or venting systems, making them a more environmentally friendly option. In addition, electric boilers are very reliable and provide precise temperature control for improved comfort and energy efficiency. Electric boilers are simple to operate, noiseless and thermally efficient, but the relatively high cost of electrical energy limits their use in large-scale industrial production.

What are the most common boiler types?

Currently, in the industrial sector, common boiler types include coal-fired boilers, oil and gas boilers, and biomass-fired boilers. These boiler types play an important role in different applications, providing reliable thermal energy for processes such as heating, production and energy conversion.

Gas oil fired molten salt boiler

Oil Gas Boilers

Oil-fired gas boilers are a common boiler type chosen by many because of their stable energy supply, high energy efficiency, cleanliness, environmental friendliness, adaptability and simple equipment structure.

Oil-fired gas boilers are suitable for a wide range of sizes and types of applications, from small industrial plants to large commercial buildings, hospitals, schools and other places where hot water and steam are required. Oil-gas boilers also have a certain load adaptability and are able to automatically adjust their operation according to changes in the actual heat load.

In order to make the boiler more efficient, the EPCB oil-fired gas boiler updates the three-way wetback structure to the fourth generation, and uses a large-diameter corrugated liner and internal and external double-threaded flue tubes to increase the boiler's heat exchange efficiency. Special materials such as aluminosilicate fibre and aluminium foil are also used as boiler insulation to effectively reduce heat loss. At the same time, EPCB is equipped with highly efficient energy-saving devices such as finned-tube energy savers, which can reduce temperatures down to as low as 110 degrees Celsius.

The thermal efficiency of EPCB's fuel gas boiler system can reach over 98%. If equipped with a condensation recovery device, the latent heat of gaseous water in the flue gas is then recovered. The thermal efficiency of the boiler system can reach over 102%.

Coal-fired boiler

Coal is a widely available and resourceful fuel, and many regions have abundant coal reserves. Therefore, the use of coal-fired boilers is not limited by the supply of fuel and can meet the energy needs of most regions. Compared with other fuels, the price of coal is relatively low, which gives coal-fired boilers an advantage in investment and operating costs. In addition, the design and technology of coal-fired boilers have been developed and improved for a long time, and they have stable and reliable operation performance.

Therefore, coal-fired boilers are widely used in many industries, such as power plants, petrochemical factories, textile factories, paper mills and so on. Coal-fired boilers are able to meet the demand for large amounts of thermal energy in these industries and have the ability to adapt to different working conditions and demands.

It should be noted that with the increasing concern for environmental protection, many countries and regions will gradually shift to cleaner energy sources. Don't worry, EPCB coal-fired boilers adopt advanced combustion control technology and flue gas purification equipment, which improves the combustion efficiency, reduces the emission level of coal-fired boilers, and reduces the impact on the environment.

Biomass-fired boilers

The biomass boiler is a boiler that uses renewable biomass materials as fuel. It can use waste, crop straw, wood chips and other biomass to generate heat for heating or power generation.

The use of biomass-fired boilers in industries such as wood processing, food processing, pulp and paper is based on the renewable and environmentally friendly nature of biomass fuels, as well as the need for sustainability and carbon emission control. By utilising biomass resources such as waste, crop residues and other biomass resources, biomass-fired boilers are able to provide a clean, renewable supply of heat energy, reducing reliance on traditional energy sources and enabling green and sustainable production methods.

EPCB biomass-fired boilers are ideal for sustainable energy applications due to their multi-fuel adaptability, high energy efficiency, environmental friendliness and low emissions, stability and reliability, intelligent control and customised design.

EPCB-Professional Boiler Manufacturer

EPCB, as a professional boiler manufacturer, not only supports boiler customisation, but also provides design suggestions for complete production lines, offering customers one-stop solutions. Whether it is the need for industrial boilers or the planning of production lines, EPCB can customise and design according to the specific requirements and application scenarios of customers.

In terms of boiler customisation, EPCB is committed to meeting the specific needs of its customers. Customers can communicate with EPCB's professional team based on their needs, fuel selection, process requirements, etc. EPCB will provide customised boiler designs based on the customer's requirements, including boiler type, capacity, combustion system, and heat recovery device. Such customised design ensures that the boiler matches the customer's production process and energy requirements, achieving optimal energy efficiency and economic benefits.

In terms of production line planning, EPCB also provides complete production line design advice to assist customers in the planning and layout of their production lines. Whether it is a new construction project or an upgrade of an existing plant, EPCB's team of professionals will provide advice on optimising the layout of the production line according to the customer's needs and actual situation.

For example:Textile printing and dyeing production line: EPCB through more than 30 years of careful research and service in the sizing industry, from the customer's first use of the site, to provide a stable, safe and reliable full set of heat source service system, through the pre-medium and post-professional customised services, to help minimise the brittle breakage of sizing yarns, to increase the rate of sizing hanging, to ensure the rate of damp return, to increase the rate of weavability, from the reduction of operating costs.

Pulp and paper production line: EPCB, according to the customer's needs and existing equipment, at the beginning of the boiler selection, the layout and equipment selection for pulp preparation, papermaking process, paper processing and other aspects of the layout and equipment selection, to maximise boiler efficiency, in order to improve production efficiency, reduce energy consumption, and ensure product quality.

Chemical production line: For the chemical industry, EPCB can provide design suggestions for chemical production lines. According to the needs of different chemical processes, it includes process optimisation and equipment layout for raw material handling, reactor configuration, separation process, etc., in order to improve production efficiency, reduce energy consumption and minimise waste generation.

Conclusion

Regardless of the industry, EPCB can provide customised boiler solutions according to customers' specific needs and requirements.EPCB not only focuses on boiler design and manufacturing, but also provides a full range of service support. From pre-sales consultation, equipment selection to installation and commissioning and operation training during the sale, EPCB's professional team will accompany customers throughout the whole process to ensure that the boiler is put into operation smoothly. With rich experience, professional team and comprehensive services, EPCB has won the trust and praise of our customers, EPCB, your personal boiler system experts!

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025