Industrial Steam Boiler: High Efficiency, Low Cost—Why Us?

Water Tube Gas Fired Steam Boiler: What’s Moving the Market Now

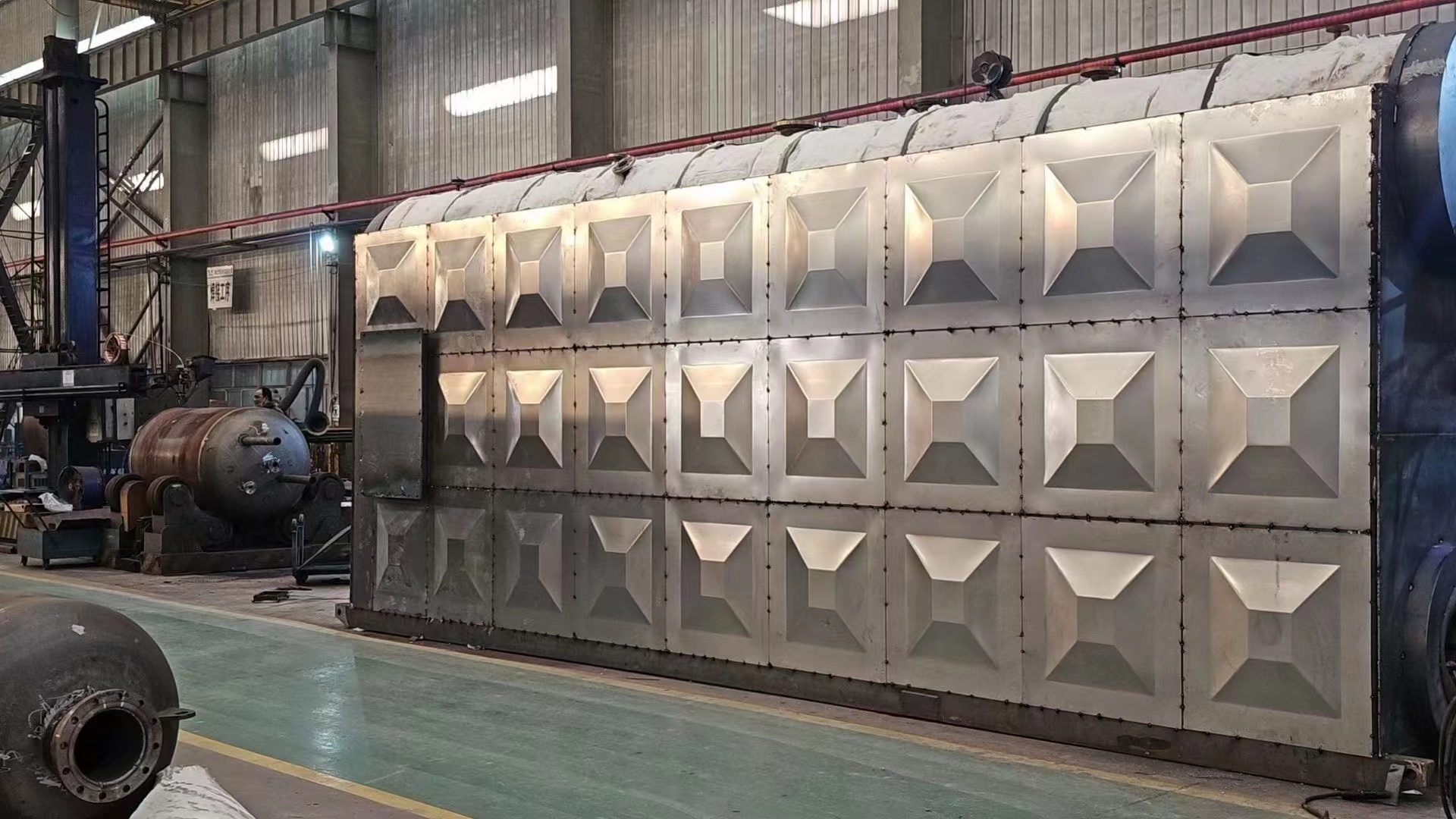

If you’ve been shopping for an industrial steam boiler, you’ve probably noticed the same thing I have: efficiency and low-NOx aren’t just buzzwords anymore—they’re baseline. This double-drum, water-tube design from Wuqiao, Hebei, China keeps popping up in bids, and, to be honest, it’s because the numbers are competitive and the layout is service-friendly.

Industry trends I’m seeing

- Low-NOx burners and O2 trim as standard, sometimes with SCR add-ons for sub-30 mg/Nm³.

- Smart controls (PLC + remote monitoring) for fuel maps, alarms, and predictive maintenance.

- Economizers/condensing heat recovery pushing seasonal efficiency into the mid-90s% (LHV).

- Hydrogen blends—still cautious, but many vendors are testing up to 10–20% H₂ by volume.

Quick product specs (real-world use may vary)

| Product | Water tube double-drum gas/liquid oil fired steam boiler |

| Evaporation capacity | ≈ 6–35 t/h (larger on request) |

| Design pressure | 1.25–2.5 MPa (others per code) |

| Steam | Saturated standard; superheat optional |

| Fuel | Natural gas, LPG, diesel, light oil |

| Efficiency (LHV) | ≈ 92–95% with economizer; higher with condensing |

| NOx | ≈ 30–80 mg/Nm³ with low-NOx burner (site-dependent) |

| Controls | PLC, touch HMI, O2 trim, VFD fan |

| Origin | Wuqiao, Hebei, China |

How it’s built and verified

Materials: drum plates (SA-516 Gr.70 or equivalent), tubes (SA-192/SA-210/SA-213 as applicable), headers in matched grades. Methods: CNC cutting, submerged arc welding, tube-to-header orbital welding, PWHT where code requires. Testing: NDE (RT/UT/MT) per ASME V; welder quals per ASME IX; hydrostatic test at ≈1.5× design pressure; burner tuning for O₂ and CO. Typical service life? Around 20–25 years with proper water treatment and periodic retubing.

Common standards/certifications: ASME Section I (Power Boilers), EN 12952 (water-tube), GB/T 16507, ISO 9001 quality system. Emissions validation often checked against local regulations or EU MCPD limits. I’ve seen stack O₂ trimmed to ~2.5–3.0% for steady, clean burns.

Where it fits

Food & beverage (CIP, blanching), textiles (dyeing), pharmaceuticals (clean steam via secondary exchangers), chemicals, paper, and district energy. Many customers say the step from shell boilers to a industrial steam boiler like this is mostly about responsiveness and turndown.

Real-world notes and feedback

- Case 1 (textile, Southeast Asia): reported 12% fuel savings after economizer upgrade; NOx ≈ 45 mg/Nm³.

- Case 2 (beverage, Middle East): steam stability improved; CO

- Case 3 (paper mill, EU): SCR add-on brought NOx to ≈ 25 mg/Nm³; seasonal uptime > 98%.

Vendor landscape (my quick take)

| Vendor | Efficiency (LHV) | NOx Options | Customization | Lead Time |

|---|---|---|---|---|

| YN Boilers (China) | ≈92–95% (condensing higher) | Low-NOx, SCR optional | High (drum, layout, controls) | Competitive; varies by size |

| Bosch / Loos | ≈92–96% | Low-NOx, SCR | Medium–High | Moderate |

| Cleaver-Brooks | ≈90–95% | ULN, SCR options | High | Moderate–Long |

| Miura | ≈90–94% | Low-NOx | Medium | Short–Moderate |

Bottom line: if you need a flexible industrial steam boiler with a solid efficiency/price ratio and code-compliant documentation, this water-tube platform is worth shortlisting.

Authoritative citations

- ASME Boiler and Pressure Vessel Code, Section I: Power Boilers.

- EN 12952: Water-tube boilers and auxiliary installations.

- GB/T 16507: Water-tube boilers (China National Standard).

- ISO 9001: Quality management systems—Requirements.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025