Reliable Industrial Steam Boiler - High Efficiency & Cost-Effective

Introduction to Advanced Industrial Steam Boilers

The demand for efficient, reliable, and sustainable energy solutions in industrial sectors has never been higher. At the core of many critical operations, from power generation to complex manufacturing, lies the industrial steam boiler. These sophisticated systems convert water into high-pressure steam, a versatile energy carrier essential for various processes. This comprehensive guide delves into the intricate world of industrial steam boilers, focusing on their manufacturing, technical specifications, diverse applications, and the factors critical for selection and long-term operational success. We aim to provide B2B decision-makers and engineers with the authoritative insights needed to navigate this vital equipment landscape.

Modern industrial boilers are engineered for optimal performance, often leveraging advanced combustion technologies and robust material science to deliver unparalleled efficiency and reduced environmental impact. Understanding the lifecycle, from design and fabrication to deployment and maintenance, is paramount for maximizing return on investment and ensuring operational continuity. This article will also explore emerging trends, offer detailed comparisons, and present compelling case studies to illustrate real-world value.

Manufacturing Process of an Industrial Steam Boiler

The production of a high-performance industrial steam boiler is a multi-stage process demanding precision engineering, advanced material science, and rigorous quality control. Our water tube gas fired steam boilers exemplify this commitment to excellence.

Key Stages:

- 1. Design and Engineering: Utilizing advanced CAD/CAM software, boiler designs are optimized for thermal efficiency, structural integrity, and adherence to international standards like ASME Boiler and Pressure Vessel Code. Material selection is critical, with high-strength carbon and alloy steels (e.g., SA-106 Gr. B, SA-210 Gr. A1) chosen for pressure parts, resisting high temperatures and pressures.

- 2. Material Procurement & Preparation: Raw materials, including seamless steel tubes, plates, and structural components, are sourced from certified suppliers. Each batch undergoes incoming material inspection for chemical composition and mechanical properties. Cutting is performed using CNC plasma or laser cutting for high accuracy.

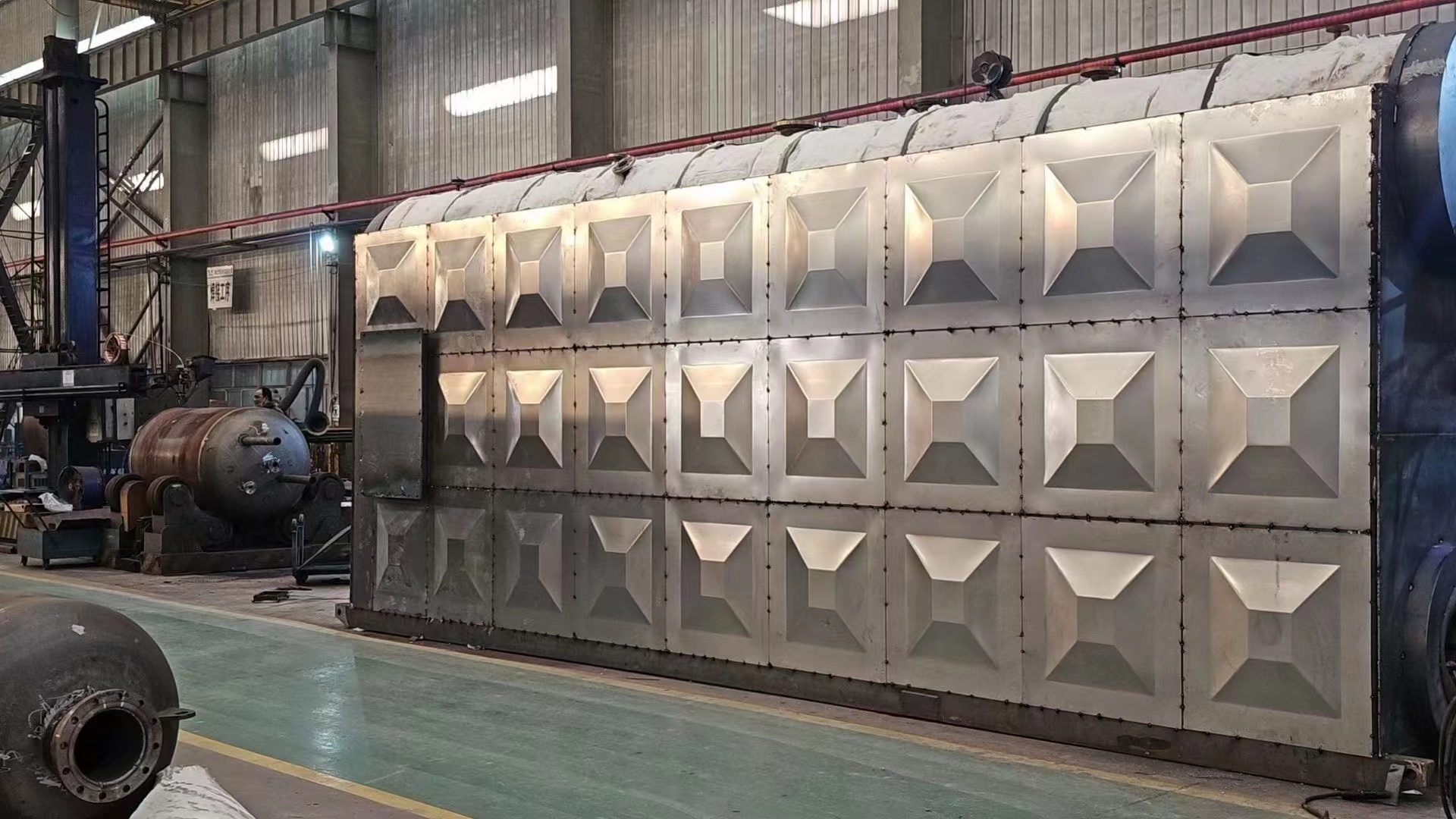

- 3. Tube Bending and Panel Fabrication: Water tubes are precisely bent using cold bending or hot bending techniques, ensuring wall thickness integrity. Membrane wall panels, comprising tubes welded together with fin material, are fabricated using automated welding lines, ensuring consistent weld quality and structural rigidity. This process often involves robotic welding for enhanced precision and speed.

- 4. Drum and Header Manufacturing: Boiler drums and headers, critical pressure vessels, are manufactured from thick steel plates (e.g., SA-516 Gr. 70). This involves forming (rolling), welding (submerged arc welding), and post-weld heat treatment (PWHT) to relieve residual stresses and enhance material toughness. All welds are subjected to non-destructive testing (NDT) such as ultrasonic testing (UT) and radiographic testing (RT).

- 5. Assembly: Major components – drums, headers, membrane walls, economizers, and superheaters – are assembled within the fabrication shop. This involves precise fit-up and extensive welding, adhering to strict welding procedure specifications (WPS) and qualified welders (WPQ).

- 6. Hydrostatic Testing: Once assembled, the pressure parts of the boiler undergo hydrostatic testing. This involves filling the boiler with water and pressurizing it to 1.25 to 1.5 times the design pressure, as per ISO 9001 and ANSI standards, to verify leak-tightness and structural integrity under design conditions.

- 7. Insulation & Casing: After successful pressure testing, the boiler is insulated with high-temperature refractory materials and mineral wool to minimize heat loss. An outer steel casing protects the insulation and provides structural support.

- 8. Controls & Auxiliaries Integration: Burner systems, control panels, safety valves, pumps, and other auxiliary equipment are installed and wired, ensuring seamless operation and adherence to safety protocols.

- 9. Final Inspection & Certification: A comprehensive final inspection, including functional tests of controls and safety interlocks, is conducted. The boiler is then certified by third-party inspection agencies, confirming compliance with all applicable codes, standards, and customer specifications. Our boilers typically exceed industry benchmarks for service life, often exceeding 20-25 years with proper maintenance.

This meticulous process ensures that each industrial steam boiler delivered is a product of superior quality, engineered for durability and peak performance.

Industry Trends in Industrial Steam Boilers

The landscape for industrial steam boiler technology is continuously evolving, driven by stringent environmental regulations, rising energy costs, and the increasing demand for operational efficiency. Key trends include:

- Decarbonization and Fuel Flexibility: A significant shift towards cleaner fuels like natural gas, biogas, and hydrogen, alongside advanced multi-fuel capabilities to reduce carbon emissions and achieve sustainability goals. The Water tube gas fired steam boiler exemplifies this trend.

- Enhanced Energy Efficiency: Integration of economizers, air preheaters, and advanced burner technologies to capture waste heat and optimize combustion, leading to efficiencies often exceeding 95%.

- Digitalization and IoT Integration: Implementation of smart control systems, remote monitoring, and predictive maintenance capabilities using Industrial IoT (IIoT) sensors. This allows for real-time performance optimization, reduced downtime, and proactive problem-solving.

- Modular and Compact Designs: Increasing preference for skid-mounted or modular boiler systems that offer faster installation, reduced footprint, and greater flexibility for plant expansion or relocation.

- Robust Safety and Compliance: Continuous advancements in safety features and control logic to meet global standards (e.g., European Pressure Equipment Directive, OSHA, CSA) and minimize operational risks.

Technical Specifications and Parameters

Understanding the detailed technical specifications is paramount when considering an industrial steam boiler. Our water tube gas fired steam boilers are designed with precision to meet diverse industrial requirements.

Typical Specifications for a Water Tube Gas Fired Steam Boiler:

| Parameter | Value/Range |

|---|---|

| Rated Steam Capacity | 4 - 75 T/h (Tonnes per hour) |

| Rated Steam Pressure | 1.0 - 5.3 MPa (10 - 53 bar) |

| Steam Temperature | 184 - 450 °C (Saturated to Superheated) |

| Design Thermal Efficiency | ≥ 92% (up to 98% with economizer/condenser) |

| Fuel Type | Natural Gas, LPG, Biogas, City Gas, Coke Oven Gas |

| NOx Emissions | Low NOx |

| Automation Level | Fully Automatic PLC Control with HMI |

| Design Life | 20-25 Years (minimum, with proper maintenance) |

| Standards Compliance | ASME, ISO, CE, GOST, DOSH |

These parameters are critical for specifying the right boiler for a given application, ensuring optimal performance, energy efficiency, and compliance with local and international regulatory frameworks.

Application Scenarios and Target Industries

The versatility of the industrial steam boiler makes it indispensable across a vast array of sectors. Its ability to provide consistent, high-quality steam for heating, sterilization, and power generation underpins numerous industrial processes.

Key Target Industries and Applications:

- Petrochemical & Chemical Industry: Steam is crucial for process heating, distillation, reactor heating, and stripping operations. The need for precise temperature control and explosion-proof designs is paramount here.

- Food & Beverage: Sterilization of equipment, pasteurization, cooking, and drying processes heavily rely on clean steam. Compliance with FDA standards for food contact surfaces and sanitary steam generation is often required.

- Textile Industry: Dyeing, drying, and sizing processes utilize large quantities of steam. Energy-efficient boilers are essential to manage high energy consumption.

- Pharmaceuticals: Sterilization, humidification, and heating in cleanroom environments demand high-purity, contaminant-free steam. GMP (Good Manufacturing Practice) compliance is critical.

- Paper & Pulp: Steam is used for pulp digestion, paper drying, and heating various process fluids. These applications often require boilers with high steam capacities and robust designs to handle continuous operation.

- Water Supply & Drainage: While less direct, steam can be used in some water treatment processes for heating, or indirectly in power generation for municipal facilities.

- Manufacturing & General Industry: From curing processes in concrete manufacturing to vulcanizing rubber, steam provides efficient and controllable heat.

In these scenarios, the advantages of a modern industrial steam boiler are clear:

- Energy Saving: Advanced combustion and heat recovery systems drastically reduce fuel consumption.

- Corrosion Resistance: High-grade materials and precise water treatment minimize boiler tube corrosion, extending service life.

- Reliability: Robust design and stringent manufacturing ensure consistent steam supply, reducing costly downtime.

Technical Advantages and Performance Benchmarks

Our water tube gas fired steam boilers offer distinct technical advantages that set them apart in the competitive market, making them a preferred choice for companies looking to buy industrial steam boiler solutions.

Key Advantages:

- Superior Thermal Efficiency: Engineered with multi-pass flue gas designs and integrated economizers, achieving thermal efficiencies up to 98%. This directly translates to significant fuel cost savings over the operational lifespan.

- Rapid Steam Generation: Water tube design allows for quicker startup and faster response to load changes compared to fire tube boilers, providing stable steam supply on demand.

- Lower Emissions: Equipped with advanced low NOx burners and optimized combustion chambers, our boilers significantly reduce harmful emissions, easily meeting stringent environmental regulations (e.g., NOx best industrial steam boiler.

- Enhanced Safety Features: Incorporating multiple safety interlocks, high-quality pressure relief valves, and automatic control systems that continuously monitor operational parameters, ensuring safe and reliable operation.

- Modular and Compact Footprint: Designed for ease of installation and maintenance, with a relatively smaller footprint for their capacity, ideal for facilities with space constraints.

- Robust Construction & Longevity: Built with high-grade, certified materials and meticulous welding processes, ensuring durability and a service life exceeding 20 years, even under demanding operational conditions.

Vendor Comparison and Selection Criteria

When sourcing an industrial steam boiler, prospective buyers are faced with numerous options, ranging from large multinational corporations to specialized regional manufacturers, including many from china industrial steam boiler suppliers. Making an informed decision requires a systematic comparison based on critical criteria beyond just the initial purchase price.

Key Comparison Criteria:

| Criterion | High-Quality Supplier (e.g., YN Boilers) | Generic/Lower Cost Options |

|---|---|---|

| Thermal Efficiency | >95% (with economizer), often 98% | 85-90%, potentially lower without heat recovery |

| Emission Standards | Ultra-low NOx (e.g., | May struggle to meet stringent local NOx regulations |

| Material Quality | Certified ASME/ISO materials, robust wall thickness | Potentially lower grade steel, thinner sections for cost saving |

| Automation & Controls | Advanced PLC with HMI, remote monitoring, diagnostic tools | Basic controls, limited diagnostics, manual intervention needed |

| After-Sales Support | Global service network, 24/7 technical support, spare parts availability | Limited or no local support, long lead times for parts |

| Certifications | ASME, CE, ISO 9001, PED, etc., often third-party verified | May only meet minimum local standards, fewer international certifications |

| Total Cost of Ownership (TCO) | Higher initial investment, but significantly lower operating costs and longer lifespan. Offers the best industrial steam boiler value. | Lower initial investment, but higher fuel costs, maintenance, and shorter lifespan. Can be seen as a cheap industrial steam boiler initially. |

While an initially cheap industrial steam boiler might seem attractive, the long-term operational expenses, reliability issues, and potential for regulatory non-compliance often outweigh the initial savings. Investing in a high-quality boiler from a reputable manufacturer ensures superior performance, energy efficiency, and a robust support infrastructure.

Customized Solutions and Engineering Expertise

Recognizing that no two industrial applications are identical, we offer bespoke engineering services to tailor each industrial steam boiler solution to specific client needs. This goes beyond standard configurations and addresses unique operational parameters, site constraints, and regulatory requirements.

Customization Options Include:

- Fuel Flexibility: Designing boilers to operate on multiple fuel sources, including natural gas, LPG, biogas, or even specific industrial waste gases, often with seamless switching capabilities.

- Steam Parameters: Adjusting steam pressure, temperature (saturated or superheated), and capacity to precisely match process demands.

- Emission Control Systems: Integrating specialized flue gas treatment technologies (e.g., SCR, SNCR) to meet ultra-low emission targets in environmentally sensitive regions.

- Footprint Optimization: Modular or skid-mounted designs to fit into challenging plant layouts or existing infrastructure with minimal disruption.

- Advanced Control Systems: Custom PLC programming, integration with existing DCS (Distributed Control Systems), and bespoke HMI interfaces for enhanced operational control and data analytics.

- Material Upgrades: Utilizing specialized corrosion-resistant alloys for demanding applications or specific fluid chemistries.

- Ancillary Equipment Integration: Supplying and integrating complete boiler house solutions, including water treatment plants, deaerators, fuel handling systems, and steam distribution networks.

Our engineering team collaborates closely with clients from conceptualization through commissioning, ensuring the final boiler system delivers optimal performance and long-term value.

Application Case Studies

Real-world deployments demonstrate the tangible benefits of investing in a high-quality industrial steam boiler.

Case Study 1: Large-Scale Chemical Plant Energy Upgrade

- Client: A major petrochemical producer in Southeast Asia.

- Challenge: Aging boiler infrastructure leading to high fuel consumption (over 90% efficiency), frequent downtime, and non-compliance with new local NOx emission limits (target

- Solution: Supplied and installed two 35 T/h water tube gas fired steam boilers with integrated economizers and ultra-low NOx burners.

- Results:

- Increased thermal efficiency to 96.5%, resulting in 15% annual fuel cost savings.

- Reduced NOx emissions to

- 99.8% operational uptime over the first 24 months, significantly reducing maintenance costs and increasing production reliability.

- Project payback period estimated at 3.5 years.

Case Study 2: Food Processing Facility Expansion

- Client: A leading dairy product manufacturer in Europe.

- Challenge: Expansion required additional steam capacity for sterilization and pasteurization, but with limited space and strict noise/emission regulations in an urban-adjacent facility.

- Solution: Provided a compact, modular 15 T/h water tube gas fired steam boiler, specifically designed for low noise operation and equipped with a condensing economizer for maximum efficiency and a bespoke acoustic enclosure.

- Results:

- Achieved 98% thermal efficiency due to condensing economizer, leading to substantial energy savings.

- NOx emissions consistently below 15 mg/Nm³, exceeding local environmental mandates.

- Noise levels maintained below 70 dB(A) at 1 meter, satisfying community requirements.

- Rapid installation and commissioning within 6 weeks, minimizing disruption to existing operations.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for an industrial steam boiler?

-

A: Lead times vary depending on the boiler's capacity, customization requirements, and current production schedule. For standard models, lead time typically ranges from 12 to 20 weeks from order confirmation to ex-works delivery. Highly customized projects may require 20-30 weeks. We provide detailed lead time estimates during the quotation phase.

- Q: What warranty is offered on your industrial steam boilers?

-

A: We offer a comprehensive warranty of 18 months from shipment or 12 months from commissioning, whichever comes first, against manufacturing defects. Specific pressure parts often carry an extended warranty period. Full warranty terms are detailed in our sales contracts.

- Q: What kind of after-sales support do you provide?

-

A: Our commitment extends beyond delivery. We provide extensive after-sales support including:

- Technical Assistance: 24/7 remote technical support via phone and email.

- On-site Services: Commissioning, routine maintenance, emergency repairs, and performance optimization services by certified engineers.

- Spare Parts: A readily available inventory of genuine spare parts to minimize downtime.

- Training: Operator and maintenance staff training programs for safe and efficient boiler operation.

- Q: How do I choose the right industrial steam boiler for my facility?

-

A: Selecting the correct boiler involves several factors: required steam capacity, operating pressure and temperature, available fuel type, space constraints, environmental regulations, and budget. Our experienced sales and engineering teams provide consultation to assess your specific needs and recommend the optimal solution, ensuring you buy industrial steam boiler that precisely matches your requirements.

Conclusion

The selection and implementation of an industrial steam boiler is a critical strategic decision for any industrial operation. By prioritizing advanced engineering, robust manufacturing, comprehensive support, and a commitment to energy efficiency and environmental compliance, businesses can ensure long-term operational excellence and sustainable growth. Our water tube gas fired steam boilers stand as a testament to this philosophy, delivering reliable, high-performance steam generation solutions designed for the demands of modern industry.

References

- 1. ASME Boiler and Pressure Vessel Code. Section I: Rules for Construction of Power Boilers. American Society of Mechanical Engineers, 2023.

- 2. European Parliament and Council Directive 2014/68/EU on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment (recast) (PED). Official Journal of the European Union, 2014.

- 3. International Organization for Standardization. ISO 9001:2015 Quality Management Systems. ISO, 2015.

- 4. U.S. Environmental Protection Agency. "Controlling NOx Emissions from Industrial, Commercial, and Institutional Boilers." EPA Report, 2021.

- 5. CIBSE Guide B: Heating, Ventilating, Air Conditioning and Refrigeration. Chartered Institution of Building Services Engineers, 2022.

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

High-Efficiency Horizontal YQW Gas Oil Fired Thermal Oil Boiler-Hebei Yineng Boiler|Energy Efficiency,Advanced CombustionNewsNov.21,2025

-

Electric Steam Boiler Manufacturers | High-Output & SafeNewsNov.14,2025

-

OEM Steam Boiler Solutions | High-Efficiency, Custom-BuiltNewsNov.13,2025

-

Thermal Oil Boiler | High Efficiency, Low Pressure, OEMNewsNov.12,2025

-

Hebei Yineng Boiler Co., Ltd. Showcases Cutting-Edge Boiler Solutions at Indonesia International Boiler Exhibition 2025NewsNov.11,2025