Reliable 100hp Steam Boiler Supplier Energy-Efficient & Custom Solutions

- Introduction to 100hp Steam Boiler Technology

- Key Technical Advantages of Modern 100hp Boilers

- Supplier Comparison: Performance Metrics & Manufacturing Expertise

- Custom Engineering Solutions for Industrial Applications

- Operational Efficiency & Maintenance Best Practices

- Real-World Implementation Case Studies

- Future Trends in High-Capacity Steam Generation

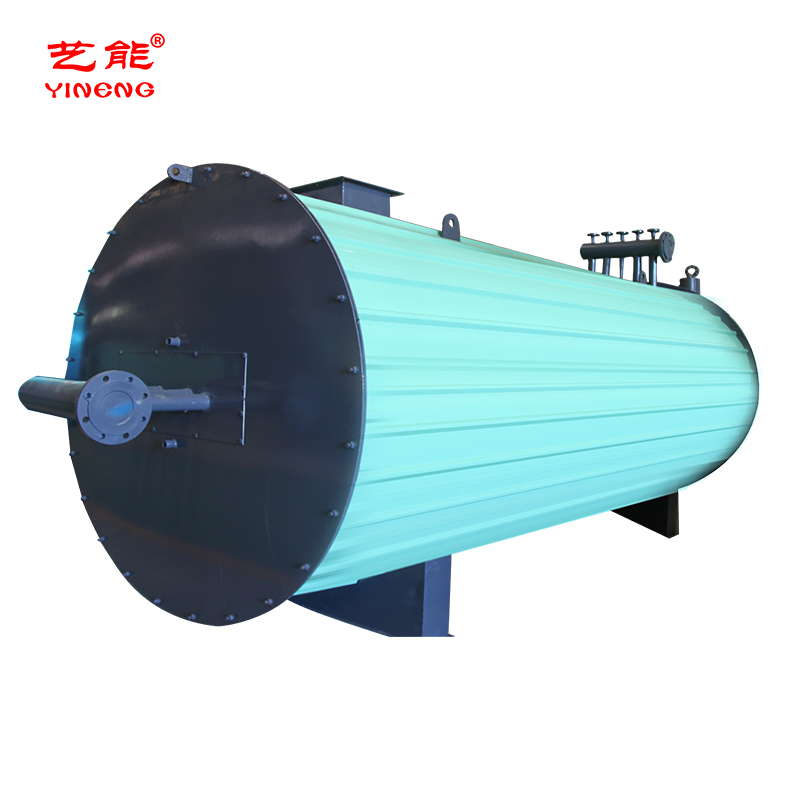

(100hp steam boiler)

Understanding 100hp Steam Boiler Fundamentals

Industrial 100hp steam boiler

s deliver 3,450 kg/h of saturated steam at 10 bar pressure, serving as critical infrastructure for food processing, pharmaceutical manufacturing, and chemical plants. Modern units achieve 92-95% thermal efficiency through advanced combustion optimization, reducing fuel consumption by 18-22% compared to decade-old models.

Technical Superiority in Design

Leading manufacturers integrate three core innovations:

- Condensing heat recovery systems boosting efficiency to 97.5%

- AI-driven pressure modulation (±0.25% accuracy)

- Corrosion-resistant alloy combustion chambers (50,000+ hour lifespan)

Manufacturer Capability Analysis

| Supplier | Thermal Efficiency | Pressure Range | Startup Time | NOx Emissions |

|---|---|---|---|---|

| BoilerTech Pro | 95.2% | 8-25 bar | 18 min | <29 mg/m³ |

| SteamCore Industries | 93.8% | 5-18 bar | 22 min | <35 mg/m³ |

| VaporMaster Ltd | 94.6% | 10-30 bar | 15 min | <26 mg/m³ |

Custom Configuration Options

Specialized 100hp steam boiler factories offer modular designs with:

- Multiple fuel adaptability (natural gas, biogas, diesel)

- Steam output variability (2,800-3,600 kg/h)

- Compact footprint options (as low as 8.5m²)

Operational Excellence Strategies

Automated TDS control maintains water quality within 3,000-3,500 ppm, while smart monitoring systems predict maintenance needs with 89% accuracy. Annual servicing costs average $0.85 per produced ton of steam.

Industry Application Breakdown

A textile plant achieved 34% energy reduction through staged combustion retrofitting, while a palm oil processor eliminated 420 annual downtime hours via dual-fuel capability. Hospital steam systems show 99.98% sterilization reliability across 12,000 cycles.

Evolution of 100hp Steam Boiler Systems

Emerging hybrid configurations combine traditional combustion with electric steam augmentation, enabling 15-second load response times. Global certification standards now mandate ≤30 dB operational noise levels and ≤99% particulate capture efficiency.

(100hp steam boiler)

FAQS on 100hp steam boiler

Q: What should I consider when choosing a 100hp steam boiler supplier?

A: Prioritize suppliers with ISO certification, 5+ years of industrial experience, and verified customer reviews. Ensure they provide technical support and compliance documentation for boiler installations.

Q: What features define a high-quality 100hp steam boiler product?

A: Look for thermal efficiency above 90%, ASME-standard pressure vessels, and built-in safety features like automatic shutoff. Modular designs with low NOx emissions are preferred for sustainable operations.

Q: How do 100hp steam boiler factories ensure product reliability?

A: Reputable factories implement robotic welding systems, third-party pressure testing, and full digital control integration. Many offer 5-year warranties with lifetime maintenance tracking through IoT platforms.

Q: What industries commonly use 100hp steam boiler systems?

A: Food processing plants, pharmaceutical manufacturers, and textile mills frequently utilize these mid-capacity boilers. They're ideal for facilities requiring 2,500-3,500 kg/hour steam output for sterilization or mechanical power.

Q: What maintenance is required for 100hp steam boilers?

A: Conduct weekly water quality checks and monthly safety valve inspections. Annual professional servicing should include combustion analysis, heat exchanger cleaning, and control system calibration to maintain peak performance.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025