Efficient Thermal Oil Boilers with AI Optimization | Superior Performance

The global thermal oil boiler market exceeded $1.7 billion USD in 2023, with a projected CAGR of 5.3% from 2024 to 2029 (MarketsandMarkets). Demand is driven by industries requiring stable, indirect heating at temperatures up to 320–350°C without pressurization, such as petrochemicals, metallurgy, textiles, and pharmaceuticals.

Key trends include automation, lower NOx emissions, digital remote monitoring, and modular design. OEM boiler thermal oil suppliers are seeing increased requests for tailor-made, compact systems with strict ISO and ANSI/ASME certification compliance.

A thermal oil boiler is a closed-loop heat transfer system utilizing organic heat transfer fluids (thermal oils) to supply consistent high temperatures up to 350°C at low system pressures. Unlike water-steam boilers, thermal oil system solutions operate with reduced risk of scaling and corrosion.

Boiler thermal oil heaters are essential for:

- Indirect process heating in chemical & food industries

- Heavy oil extraction & pipeline heating

- Textile dyeing & finishing lines

- Biomass, asphalt, and bitumen plants

| Manufacturer | Heat Output (kcal/h) |

Max. Working Temp (°C) | Fuel Type | Efficiency (%) | Emission Standard | Certifications |

|---|---|---|---|---|---|---|

| Yongxing/OEM | 120,000–8,000,000 | 350 | Gas, Diesel | 92–95 | EN, UL, GB | ISO9001, CE |

| Thermax | 100,000–3,000,000 | 340 | Oil, Gas, Coal | 88–92 | EU, US EPA | ISO, ASME |

| Babcock Wanson | 150,000–5,000,000 | 350 | Gas, Oil | 89–94 | EU Ecolabel | EN, ISO |

| Yongxing YQW/L | 140,000–7,000,000 | 350 | Natural Gas/Diesel | 93–96 | ISO, GB/T | ISO9001, ISO14001 |

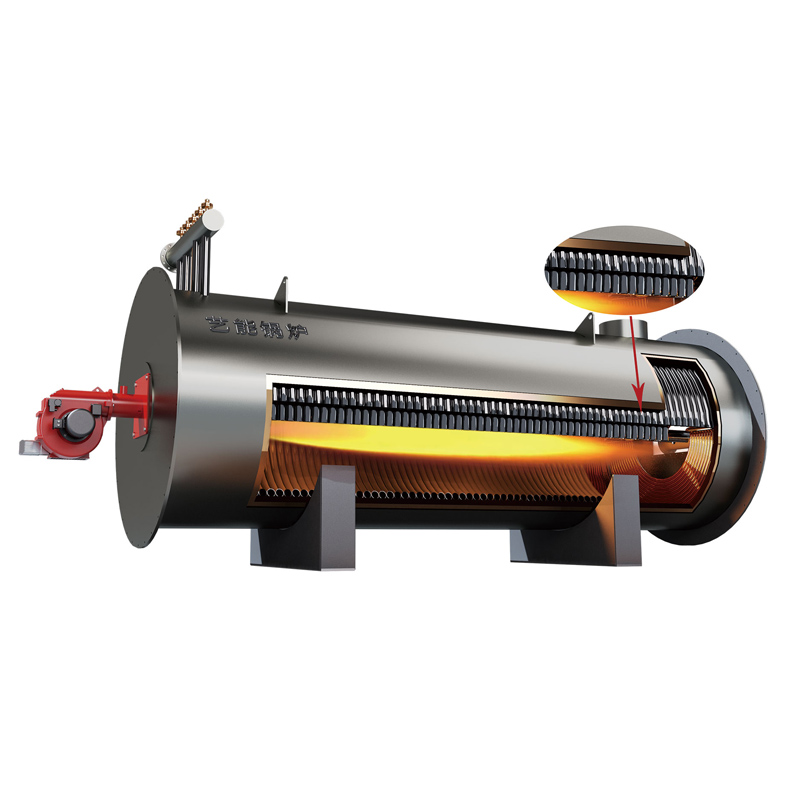

The Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater is a flagship product designed for high durability, optimal heat efficiency, and broad industrial adaptability.

Key Technical Advantages:

- Full Corrugated Furnace: Enhanced heat exchange, thermal expansion tolerance

- Three-Pass Coil Design: Minimizes thermal stress, boosts efficiency up to 96%

- High-Precision CNC Machining: Ensures consistent weld quality, surface flatness

- Top-Grade Materials: Q245R/316L pressure vessel steel, Supreme anti-corrosion alloy pipes

- Testing & Certification: 100% radiographic welding inspection, hydrostatic pressure >2.5 MPa, ISO 9001/14001, CE, ASME/ANSI compliant

- Advanced Control: SIEMENS PLC/Touchscreen, fault auto-diagnosis & remote connectivity

- Service Life: Designed for 15–20 years continuous operation with minimal scaling

(ISO5817 Level B)

| Model | Rated Heat Output (x104 kcal/h) |

Working Temp (°C) | Rated Pressure (MPa) | Fuel | Efficiency (%) | Thermal Oil Volume (L) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| YQW-140 | 140 | 320 | 0.8 | Natural Gas, Diesel | 93 | 980 | 8200 |

| YQW-350 | 350 | 320 | 0.8 | Natural Gas, Diesel | 94 | 2020 | 10980 |

| YQL-700 | 700 | 340 | 0.8 | Gas/Diesel | 95 | 3400 | 18800 |

| YQL-1400 | 1400 | 350 | 0.8 | Gas/Diesel | 96 | 6300 | 25500 |

- 15+ years of proven field performance in 120+ countries

- Trusted by BASF, Sinopec, Honeywell, and global EPC contractors

- OEM/ODM customization with detailed technical support

- Full compliance: ISO9001, ASME/ANSI, PED, CE certified

Solution: 2x YQL-1400 vertical thermal oil boiler systems, full remote PLC monitoring

Result: Achieved 33% energy cost reduction over outdated steam heating. Extended pipeline lifespan by 5+ years due to low corrosion design. Ongoing runtime >8700 hours/year, certified to API/ISO/EN.

Customer Feedback: “Stable output and almost zero maintenance. PLC/remote diagnostics greatly assist our O&M team.” – Senior Engineer, Petronas

System: YQW-700 horizontal, textile-dedicated thermal oil system with dual fuel boiler thermal oil burner

Advantage: Flexible fuel use (LNG/diesel), achieving over 94% system efficiency as verified by TÜV SÜD. Outperformed previous water/steam unit in both turn-down ratio and ramp-up speed.

Highlights: Anti-scouring coil design, OEM boiler thermal oil auxiliary expansion tank, full EN12953 coding. Localized remote troubleshooting via encrypted gateway.

- Factory Inspection: Third-party (SGS, TUV, Lloyd’s) audit available

- Production Lead Time: 15–30 days ex-works, sea-freight worldwide

- Warranty: Standard 24 months or 15,000 running hours

- After-Sales Support: 24h hotline, remote PLC online service, on-site engineering within 72h (major markets)

All delivered thermal oil boiler units are certified per ISO 9001:2015 and comply with CE/PED for EU circulation.

A: Q245R pressure vessel steel and 316L high-temperature alloy, delivering superior corrosion resistance and thermal stability required by EN10216-2 and ASME standards.

A: Synthetic (e.g., BP Transcal N, Mobiltherm) or mineral based oils with low vapor pressure, flash point above 220°C, demonstrated thermal stability at 340°C, and compatibility with system seals/gaskets.

A: Low-NOx burners, swirl flame configuration, and economizer integration minimize NOx and CO emissions to <80mg/Nm³, conforming to EU/EPA/GB 13271 standards.

A: Annual inspection for coil scaling/oxidation, burner tuning every 4000 hours, with online diagnostic systems for predictive maintenance.

A: GB/T 17410, EN12953, and ASME BPVC Section I, with full circuit pressure/temperature trials and safety interlock calibration.

A: Yes, bespoke sizing, control logic (PLC, DCS), auxiliary (expansion tank, pump), and modular skid units are available via our OEM boiler thermal oil solution program.

A: Multilingual online support, free commissioning supervision, user/operator manuals in EN/RU/ES, plus third-party inspection reports on request.

The Horizontal/Vertical type YQW/L gas or diesel oil fired thermal oil boiler heater provides a benchmark for durability, flexibility, and efficiency due to advanced welded construction, ISO/ASME-standard QA systems, and proven field reliability.

Whether for chemicals, textiles, or heavy industry's strictest requirements, investing in a next-generation thermal oil system means higher safety, lower running cost, longer service life, and robust third-party certification.

[1] “2023 Global Thermal Oil Boiler Market Analysis”, MarketsandMarkets

[2] J. Schneider, "Operation and Maintenance of Thermal Oil Systems", ScienceDirect

[3] “Boiler Thermal Oil Systems — Practical Selection”, Industrial Forum

[4] ISO 9001:2015 Quality Management, ISO.org

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025