Top Electric Steam Boiler Manufacturers – High Efficiency & Reliability

In the evolving field of industrial heating, selecting a reliable and technologically advanced electric steam boiler manufacturers is crucial. These manufacturers offer solutions for industries ranging from food processing and chemical production to healthcare, textiles, and more. As the world shifts toward higher energy efficiency, electrification, and reduced carbon footprints, understanding the market for electric steam boiler manufacturers along with growing alternatives like gas steam boiler for sale, water tube steam boiler, wood steam boiler, or the robust weil mclain eg 40 steam boiler becomes vital for decision-makers in procurement, engineering, and operations.

About Hebei Yineng Boiler Co., Ltd

Company: Hebei Yineng Boiler Co., Ltd

Location: Wuqiao, Hebei, China

Phone: +8613833185003

Email: leesonzhou@aliyun.com

Website: https://www.ynboilers.com

As one of the leading electric steam boiler manufacturers in China, Hebei Yineng Boiler Co., Ltd is devoted to innovation, efficiency, and client success. With years of manufacturing expertise, the company delivers high-quality electric, gas, and fuel-type industrial boilers tailored to modern requirements, with a strong focus on energy conservation and safe operation.

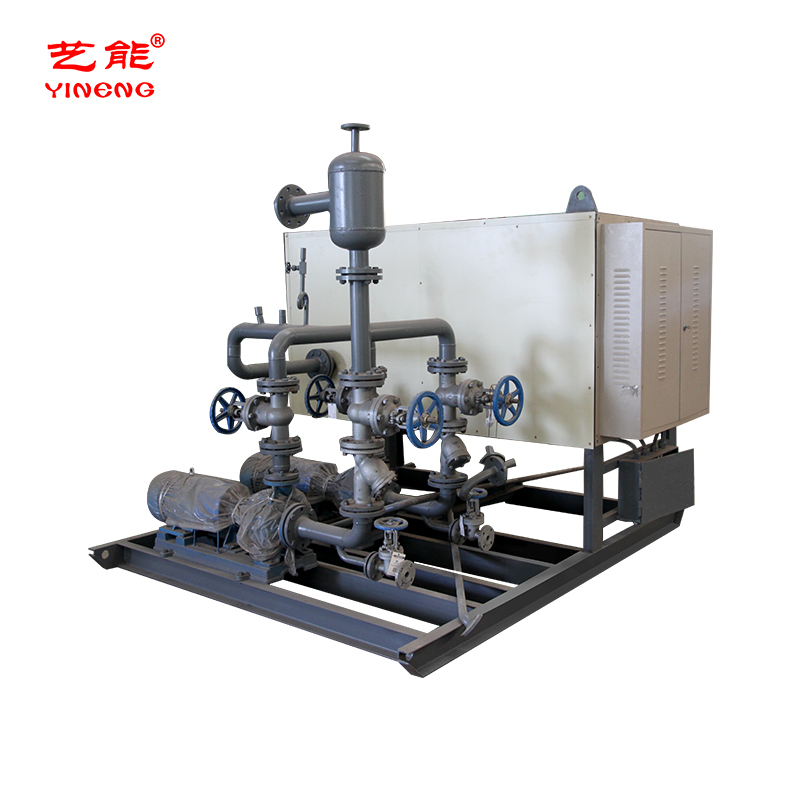

Electric steam boiler manufacturers Product Highlight: Electric Heating Thermal Oil Boiler

Product Name: Electric Heating Thermal Oil Boiler

Product Overview: The electric heating and heat transfer oil furnace represents a new generation of safe and energy-saving boilers. Utilizing heat transfer oil as the carrier, this system offers uniform heating, high thermal efficiency, and low installation requirements. With precise temperature control and no direct emissions, the solution meets the needs of diverse industrial scenarios prioritizing environmental stewardship.

Product Details: For more, visit the official product page: https://www.ynboilers.com/electric-heating-thermal-oil-boiler.html

Industry Trends: The Rise of Electric Steam Boiler Manufacturers

The global demand for electric steam boiler manufacturers is on an upward trajectory, driven by the growing emphasis on decarbonization and stricter emission standards. The rapid advancement of smart control systems, IoT, and composite materials has led to more reliable and efficient boiler solutions.

According to industry reports, the shift from fossil-fuel to electric models is expected to accelerate, making electric steam boilers a preferred option for industries with high demands on cleanliness, precise control, and sustainability. Sectors such as pharmaceuticals, textiles, chemicals, food and beverage, and electronics are at the forefront of adopting electric steam, benefiting from rapid startup times, minimal infrastructure costs, and reduced maintenance efforts.

- Stricter emission policies accelerating zero-emission boiler adoption.

- Electric models compete strongly against gas steam boilers for sale, especially in highly regulated industries.

- Growing integration of advanced thermostat for steam boiler, energy management systems, and remote diagnostics to optimize performance and safety.

Comparative Table: Key Technical Parameters of Leading Electric Steam Boiler Manufacturers

| Brand | Model | Steam Capacity (kg/h) | Rated Power (kW) | Thermal Efficiency (%) | Voltage (V) | Pressure (MPa) | Control System | Material |

|---|---|---|---|---|---|---|---|---|

| Hebei Yineng Boiler | YN-EBS-L600 | 600 | 420 | 97–99 | 380/415 | 1.0–1.6 | PLC Smart Control | Stainless Steel 304/316 |

| Cleaver Brooks | CBEX-E | 900 | 675 | 98 | 480 | 1.25 | Hawk 4000 | Carbon Steel |

| Fulton | FB-E | 730 | 520 | 98 | 400 | 1.0 | Microprocessor | Stainless Steel |

| Weil Mclain | EG 40 Steam Boiler | 320 | 235 | 85 | 240 | 1.0 | Digital Control | Cast Iron |

| Reimers | RX Series | 200 | 150 | 98 | 208-480 | 0.7-1.0 | Digital PID | Stainless Steel |

| Hebei Yineng Boiler | YN-WTB-1000 | 1000 | 700 | 98 | 380/415 | 1.6 | Touchscreen | Dual Alloy Steel |

Data Visualization: Trends & Technical Comparisons in Electric Steam Boiler Manufacturing

Application Scenarios: Where Electric and Gas Steam Boilers Excel

Electric steam boiler manufacturers offer equipment widely adopted in scenarios demanding rapid deployment, clean operation, and precise heat control. Typical steam boiler industrial applications include:

- Pharmaceutical and Biotech – Sterilization, batch process heating, and clean-steam applications.

- Food & Beverage – Steam for pasteurization, cooking, CIP (Cleaning In Place), and direct ingredient processing.

- Chemical & Petrochemical – Process steam requiring stable temperatures, minimal residue, and controlled atmospheres.

- Textiles – Dyeing, drying, printing using consistent steam temperature.

- Healthcare – Autoclaving, space heating, equipment sterilization with reliable and hygienic steam supply.

- Manufacturing – Adhesion, cleaning, curing processes needing rapid response and controllability, often demanding specific thermostat for steam boiler integration.

- Energy – Supplementary heating, pre-heating, and pilot steam for renewable/hybrid energy systems.

Product Deep-Dive: Electric Heating Thermal Oil Boiler

- Rated Power: 200–350 kW (Customizable up to 700 kW and above)

- Max Working Temp: 350℃

- Thermal Efficiency: 98%

- Working Pressure: 1.0–1.6 MPa

- Heating Surface: 8–21㎡

- Heating Medium: Heat Transfer Oil (Thermal Oil)

- Control: PLC Automatic + Smart Thermostat for steam boiler

- Core Material: Industrial Graded Alloy Steel, Seamless Tube

- Scope of Use: Petrochemical, plastics, textiles, coating industries and more

Unlike conventional boilers, the Electric heating thermal oil boiler does not require a water treatment system or condensed water recycling, making installation significantly easier and lowering total lifecycle costs. Advanced heat exchanger design ensures rapid and uniform heat transfer, while PLC+pid control enhances safety and stability. For full specifications, visit product page.

According to the International Journal of Hydrogen Energy, modern electric boilers can convert up to 99% of input energy to useful heat, outperforming most combustion-based gas boilers in efficiency.

Professional FAQ: Key Technical Terms and Standards in Electric Steam Boilers

- 1. What is the standard material used for electric steam boilers?

- The main materials include stainless steel (types 304/316), carbon steel, and sometimes dual alloy steels for enhanced durability and corrosion resistance. For industrial-grade electric steam boiler manufacturers, compliance with ASME or EN standards is recommended (ASME BPVC).

- 2. How do electric and gas steam boilers differ in installation standards?

- Electric steam boilers feature simpler installation due to the absence of combustion gas, flue, and fuel supply lines. Gas steam boiler for sale requires compliance with local fuel supply codes, gas detection, exhaust emission control, and sometimes more complex safety interlocks.

- 3. What is a heat exchanger in a steam boiler?

- The steam boiler heat exchanger is the core part where thermal energy from electric or fuel heaters is transferred to water/steam circuit, often made from high-grade seamless tubes to withstand pressure and corrosion.

- 4. What does a thermostat for steam boiler do?

- This device precisely regulates water or thermal oil temperature within the set point, automatically adjusting electric power or burner operation to protect system integrity and optimize energy usage.

- 5. What are the key performance metrics for electric steam boiler manufacturers?

- These include steam capacity (kg/h), rated power (kW), thermal efficiency (%), design/operating pressure (MPa), temperature control range, material grade, and compliance with industrial safety standards.

- 6. Can electric heating thermal oil boilers be used in high temperature applications?

- Yes, with maximum temperatures of 350–400℃ and above for special models, thanks to advanced thermostatic controls and high-performance heat transfer oil.

- 7. What is unique about the Weil Mclain EG 40 steam boiler?

- The weil mclain eg 40 steam boiler is a cast iron, gas-fired steam boiler with digital controls, suitable for small to medium-scale uses, with robust design yet slightly lower thermal efficiency compared to top electric models.

Why Choose Hebei Yineng Boiler Co., Ltd as Your Electric Steam Boiler Manufacturer?

- Industry Authority: As a pioneer among electric steam boiler manufacturers, Hebei Yineng has received multiple certifications and adheres to ISO, CE, and national safety codes.

- Advanced Technology: Integration of smart control systems (PLC/PID), IoT monitoring, and modular design enables real-time diagnostics, predictive maintenance, and easy expansion.

- Customization & Flexibility: Wide range of capacities, pressure ratings, heating mediums (including heat exchanger and water tube steam boiler configurations), and compliance with specific project specs.

- Environmentally Conscious: Commitment to providing zero emission, energy-saving solutions that support your organization's ESG goals.

- Comprehensive Service: From design consultation to after-sales, technical support, and global shipping, Hebei Yineng Boiler Co., Ltd delivers excellence throughout your boiler’s lifecycle.

For purchasing advice, technical consultation, or to discuss how the Electric heating thermal oil boiler or other steam boiler solutions can enhance your operations, contact:

Tel: +8613833185003 | Email: leesonzhou@aliyun.com

Conclusion: Professional Future with Electric Steam Boiler Manufacturers

As industrial heat demand evolves, working with experienced electric steam boiler manufacturers such as Hebei Yineng Boiler Co., Ltd is critical to achieving uncompromising safety, sustainability, and production efficiency. Whether your project calls for a highly efficient electric heating thermal oil boiler, a classic water tube steam boiler, or you need to compare with available gas steam boiler for sale or robust models like the weil mclain eg 40 steam boiler, expert manufacturers deliver bespoke technology tailored to your success.

Continuous innovation, robust technical support, and adherence to international safety standards distinguish advanced manufacturers. For more information or to discuss your needs, visit electric steam boiler manufacturers. Choose forward-looking technology, and power your facility with trust and expertise.

[1] International Journal of Hydrogen Energy: Electric boiler efficiency comparison & decarbonization (view article)

[2] Power Engineering: Global Industrial Boilers Market Trends (market report)

[3] ASME Boiler and Pressure Vessel Code: Boiler Safety Standard

[4] Control.com: Advanced Controls for Steam Boiler Operations (engineering forum)

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025

-

High-Efficiency OEM Steam Boilers: Durable & Cost-Saving SolutionsNewsJul.21,2025

-

Skid Mounted Thermal Oil Boiler | Compact & Energy-Efficient HeatingNewsJul.20,2025

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025