Jan . 20, 2025 03:26

Back to list

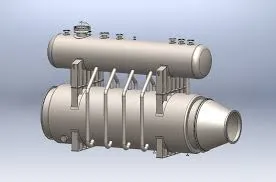

SZS double drum water tube steam boiler

In the vibrant world of textile manufacturing, the steam boiler remains an essential component, playing a pivotal role in ensuring seamless fabric production. Understanding the specific needs of a textile mill and how a steam boiler can meet these demands is crucial for optimizing operational efficiency and maintaining the highest standards of quality.

Safety and compliance must never be overlooked. A reputable steam boiler must meet strict industry standards and regulations, ensuring that it operates safely within the industrial environment of a textile mill. Regular maintenance and inspections are essential to prevent hazards such as overheating, pressure build-up, and potential boiler explosions. Partnering with manufacturers or service providers who offer comprehensive training and support can significantly enhance the safety protocols within textile facilities. A noteworthy aspect of modern steam boilers is their scale and modularity. This flexibility allows mills to adapt their energy usage to production demands, scaling operations up or down as necessary without significant energy wastage. Whether a facility is expanding or optimizing processes, the ability to customize steam output to exact specifications can lead to substantial cost savings and improved productivity. Finally, the integration of intelligent systems and IoT technology in steam boilers marks a transformative shift. These systems enable predictive maintenance and operational diagnostics, giving mill operators a deep insight into the boiler's performance metrics. Advanced analytics help in foreseeing potential issues before they manifest, leading to reduced downtime and more efficient maintenance scheduling. This integration not only improves boiler efficiency but also extends its lifecycle, ensuring that textile mills can rely on consistent, high-performance steam generation for years to come. In conclusion, the steam boiler is not merely a piece of equipment; it is the heart of a textile mill’s operations. Making informed decisions about its type, efficiency, safety, and scalability can yield tremendous benefits, including reduced operational costs, enhanced product quality, and a smaller environmental footprint. As the textile industry evolves, the adoption of advanced steam boiler technology will remain a cornerstone of its progress, positioning mills to meet the future's economic and ecological challenges head-on.

Safety and compliance must never be overlooked. A reputable steam boiler must meet strict industry standards and regulations, ensuring that it operates safely within the industrial environment of a textile mill. Regular maintenance and inspections are essential to prevent hazards such as overheating, pressure build-up, and potential boiler explosions. Partnering with manufacturers or service providers who offer comprehensive training and support can significantly enhance the safety protocols within textile facilities. A noteworthy aspect of modern steam boilers is their scale and modularity. This flexibility allows mills to adapt their energy usage to production demands, scaling operations up or down as necessary without significant energy wastage. Whether a facility is expanding or optimizing processes, the ability to customize steam output to exact specifications can lead to substantial cost savings and improved productivity. Finally, the integration of intelligent systems and IoT technology in steam boilers marks a transformative shift. These systems enable predictive maintenance and operational diagnostics, giving mill operators a deep insight into the boiler's performance metrics. Advanced analytics help in foreseeing potential issues before they manifest, leading to reduced downtime and more efficient maintenance scheduling. This integration not only improves boiler efficiency but also extends its lifecycle, ensuring that textile mills can rely on consistent, high-performance steam generation for years to come. In conclusion, the steam boiler is not merely a piece of equipment; it is the heart of a textile mill’s operations. Making informed decisions about its type, efficiency, safety, and scalability can yield tremendous benefits, including reduced operational costs, enhanced product quality, and a smaller environmental footprint. As the textile industry evolves, the adoption of advanced steam boiler technology will remain a cornerstone of its progress, positioning mills to meet the future's economic and ecological challenges head-on.

Latest news

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025