Electric Steam Boiler Manufacturers: High-Efficiency Industrial Solutions

The Crucial Role of Electric Steam Boiler Manufacturers in Modern Industry

In the rapidly evolving landscape of industrial process heating, the demand for efficient, clean, and reliable steam generation solutions is paramount. Among the diverse range of boiler technologies, electric steam boilers stand out for their operational simplicity, environmental benefits, and precise control capabilities. Understanding the intricacies of leading electric steam boiler manufacturers is crucial for industries seeking to optimize their energy consumption and adhere to increasingly stringent environmental regulations. This comprehensive guide delves into the manufacturing process, technical specifications, application scenarios, and key advantages offered by these essential industrial partners.

The shift towards electrification in industrial heating is driven by a confluence of factors, including the push for decarbonization, the availability of cleaner electricity grids, and the desire for enhanced operational flexibility. As such, the market for electric steam boilers is experiencing robust growth, positioning manufacturers at the forefront of sustainable industrial development.

Industry Trends Shaping Electric Steam Boiler Development

The industrial boiler market is undergoing significant transformation. Key trends include:

- **Decarbonization Efforts:** Governments and industries worldwide are setting ambitious targets for reducing greenhouse gas emissions. Electric boilers, especially when powered by renewable energy, offer a direct path to zero direct emissions.

- **Energy Efficiency:** Advances in insulation, control systems, and heating element design are constantly improving the efficiency of electric steam boilers, making them a competitive alternative to traditional fossil fuel systems like a gas steam boiler for sale.

- **Smart Integration:** Integration with IoT and AI for predictive maintenance, remote monitoring, and optimized operation is becoming standard. This enhances reliability and reduces downtime.

- **Compact Design:** Space-constrained industrial facilities benefit from the smaller footprint of electric boilers compared to their fuel-fired counterparts, eliminating the need for fuel storage and exhaust systems.

- **Hybrid Systems:** The emergence of hybrid solutions, combining electric boilers with other heat sources, often featuring a dedicated steam boiler heat exchanger, allows for greater flexibility and energy optimization.

These trends underscore the importance of choosing a forward-thinking electric steam boiler manufacturers that can adapt to evolving industrial needs and technological advancements.

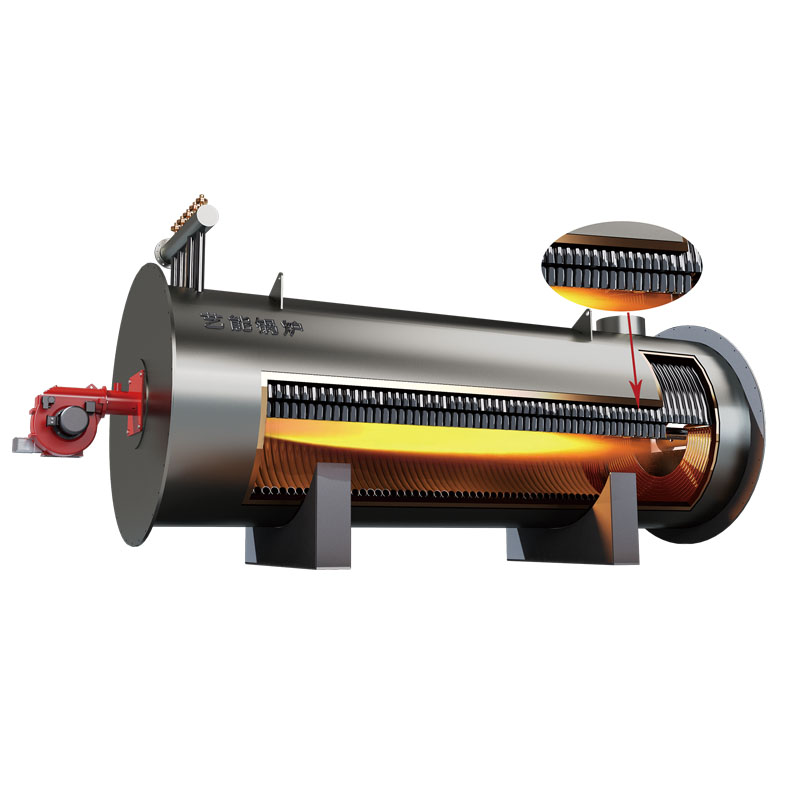

The Manufacturing Process: A Deep Dive into Electric Steam Boiler Production

The production of an electric steam boiler involves a meticulous series of steps, ensuring adherence to stringent safety and performance standards.

1. Design and Engineering:

- **Conceptualization:** Based on client requirements (steam capacity, pressure, temperature), engineers design the boiler system.

- **Material Selection:** High-grade steel (e.g., SA-516 Grade 70 for pressure vessels, specific alloys for heating elements) is chosen for its durability, corrosion resistance, and ability to withstand high temperatures and pressures.

- **Detailed CAD/CAM Design:** Precision models are created, detailing every component from the pressure vessel to the intricate control systems.

2. Component Fabrication:

- **Pressure Vessel Construction:** Steel plates undergo processes like shearing, rolling, and welding to form the boiler shell. Advanced welding techniques, often automated, ensure structural integrity and leak-proof seams. This often involves specialized techniques akin to those used in the robust construction of a water tube steam boiler.

- **Heating Element Manufacturing:** Resistance heating elements are carefully crafted, often from materials like Incoloy or Stainless Steel, designed for efficient heat transfer and long service life.

- **Fittings and Piping:** Precision CNC machining is employed for crafting flanges, nozzles, and other critical components, ensuring exact dimensions and seamless integration.

3. Assembly and Integration:

- **Internal Component Installation:** Heating elements, water level sensors, and internal baffles are installed within the pressure vessel.

- **Control System Wiring:** Electrical panels, including PLCs, safety interlocks, and a thermostat for steam boiler, are meticulously wired and integrated to ensure precise control and operational safety.

- **Insulation and Jacketing:** High-density insulation materials are applied to minimize heat loss, followed by a protective outer jacket.

4. Quality Assurance and Testing:

Rigorous testing is crucial to meet industry standards and ensure a long service life.

- **Hydrostatic Testing:** The pressure vessel is subjected to hydraulic pressure significantly higher than its operating pressure to verify structural integrity.

- **Non-Destructive Testing (NDT):** Ultrasonic and radiographic inspections are performed on welds to detect any internal flaws.

- **Functional Testing:** The boiler is operated under simulated conditions to check the performance of heating elements, controls, safety devices, and overall system response.

- **Compliance:** Adherence to standards such as ASME Boiler and Pressure Vessel Code, ISO 9001 (Quality Management), and CE marking (for European markets) is verified. ANSI standards are also critical for components.

Target Industries and Advantages:

Electric steam boilers are indispensable across various sectors:

- **Petrochemical:** For process heating where precision and explosion safety are critical.

- **Metallurgy:** Heat treatment processes requiring consistent temperature.

- **Food & Beverage:** Sterilization, cooking, and sanitation.

- **Pharmaceuticals:** Pure steam for sterile environments and processing.

- **Water Supply & Drainage:** Heating for water treatment facilities, deaeration.

- **Healthcare:** Sterilization in hospitals and laboratories.

The advantages in these scenarios are clear: energy saving through high efficiency (near 99% for electric), rapid steam generation, and inherent safety due to the absence of combustion by-products. They also offer excellent corrosion resistance with proper water treatment, ensuring a service life typically exceeding 20 years.

Technical Specifications and Parameters of Electric Steam Boilers

Understanding the technical specifications is vital for selecting the right steam boiler industrial application.

| Parameter | Range/Description |

|---|---|

| Steam Capacity | 50 kg/hr to 5,000 kg/hr (110 lbs/hr to 11,000 lbs/hr) |

| Working Pressure | 0.7 MPa to 1.6 MPa (100 PSI to 232 PSI) - Higher pressures available for specific applications |

| Thermal Efficiency | ~98% to 99.5% |

| Electrical Power Input | 30 kW to 3,000 kW (Volts: 208V to 600V, 3-phase) |

| Steam Purity | Dry saturated steam (98% dryness typically) |

| Control System | PLC-based with touch screen HMI, modulating control, auto blowdown, precise temperature regulation. |

| Footprint | Compact, significantly smaller than fuel-fired boilers of equivalent output. |

Beyond these core specifications, manufacturers often provide advanced features such as automatic descaling systems, multi-stage element activation for optimized power consumption, and robust safety interlocks conforming to global standards like EN 12952/12953.

Application Scenarios and Case Studies

The versatility of electric steam boilers allows for their deployment in a wide array of industrial and commercial settings.

Case Study 1: Pharmaceutical Manufacturing

A leading pharmaceutical company required a reliable source of clean steam for sterilization of equipment and active ingredient processing. Their existing fossil-fuel boiler often struggled with fluctuating steam demand and required extensive permitting. They installed an electric steam boiler from a reputable electric steam boiler manufacturers with a capacity of 1,500 kg/hr. The boiler’s precise temperature control and rapid response time ensured consistent steam purity (validated to USP standards) and significantly reduced start-up times. The client reported a 15% reduction in overall energy costs due to optimized operation during off-peak electricity hours and noted the ease of maintenance compared to their previous system.

Case Study 2: Commercial Laundry Facility

A large commercial laundry operation in an urban area faced strict local emission regulations and noise restrictions. Replacing an aging weil mclain eg 40 steam boiler with an electric solution proved ideal. Two 500 kg/hr electric steam boilers were installed in parallel, providing redundancy and scalability. The compact footprint freed up valuable real estate, and the silent operation eliminated noise complaints. Most importantly, the zero on-site emissions allowed the facility to comply with environmental mandates without expensive exhaust treatment systems, leading to positive public relations and streamlined operations.

Other Applications:

- **Hospitals & Healthcare:** Sterilization, humidification, heating.

- **Food Processing:** Cooking, sterilization, canning.

- **Chemical Industries:** Reactor heating, distillation.

- **Plastics & Rubber:** Curing, molding.

- **Agriculture:** Greenhouse heating, sterilization, especially where a traditional wood steam boiler might not be practical.

Technical Advantages of Electric Steam Boilers

Electric steam boilers offer a compelling suite of advantages over conventional fossil-fuel systems:

- **High Efficiency:** Near 100% thermal efficiency as almost all electrical energy is converted directly into heat within the water, eliminating stack losses.

- **Environmental Friendliness:** Zero on-site emissions of NOx, CO2, and particulate matter, contributing significantly to cleaner air and meeting environmental regulations.

- **Safety:** No combustion means no risk of explosions from fuel ignition, no open flames, and no carbon monoxide production.

- **Quiet Operation:** Without burners, fans, and exhaust systems, electric boilers operate silently, making them ideal for noise-sensitive environments.

- **Precise Control:** Modulating heating elements and advanced PLC controls allow for highly accurate temperature and pressure regulation, essential for sensitive processes.

- **Reduced Maintenance:** Fewer moving parts, no fuel pumps, no complex burner assemblies, and no flue gas treatment systems translate to lower maintenance costs and less downtime.

- **Compact Footprint:** Requires less space as there's no need for fuel storage tanks, chimney stacks, or air intake systems.

- **Rapid Start-up:** Can generate steam quickly, offering excellent responsiveness to fluctuating demand.

Vendor Comparison and Customized Solutions

Choosing among various electric steam boiler manufacturers requires careful consideration of several factors beyond just initial cost.

Key Selection Criteria:

- **Certifications & Compliance:** Look for manufacturers adhering to global standards like ASME, CE, UL, ISO 9001. These demonstrate a commitment to quality and safety.

- **Experience & Reputation:** Longevity in the industry and positive customer testimonials are indicators of reliability and expertise.

- **Customization Capabilities:** The ability to tailor boiler capacity, pressure, control features, and footprint to specific industrial needs is crucial.

- **After-Sales Support & Service Network:** A robust support system for installation, commissioning, maintenance, and spare parts is paramount for minimizing downtime.

- **Energy Management Features:** Look for features like multi-stage heating, load shedding capabilities, and integration with building management systems for optimal energy use.

The Value of Customized Solutions:

Off-the-shelf boilers may not always perfectly fit unique industrial requirements. Reputable electric steam boiler manufacturers excel in providing tailored solutions. This might include:

- **Skid-Mounted Systems:** Pre-assembled and tested units for faster installation and commissioning.

- **Specific Material Requirements:** For corrosive environments or ultra-pure steam applications, special alloys may be used.

- **Advanced Control Integration:** Custom programming to interface seamlessly with existing plant DCS or SCADA systems.

- **Redundancy and Backup Systems:** Designing N+1 configurations for critical applications where uninterrupted steam supply is essential.

EEAT: Trustworthiness and Support

Building trust with B2B clients relies on transparent and robust support systems.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for an electric steam boiler?

A: Lead times vary based on boiler size and customization. Standard models typically ship within 8-12 weeks, while custom-engineered solutions may require 16-24 weeks. Expedited options are sometimes available. - Q: What kind of warranty is offered?

A: Most manufacturers offer a comprehensive warranty, typically 12-24 months from installation or 18-30 months from shipment (whichever comes first) on components and workmanship. Pressure vessels often carry a longer warranty, up to 5 years. Specific terms should be verified with the manufacturer. - Q: How do I calculate the correct boiler size for my application?

A: Sizing requires a detailed analysis of your steam demand (kg/hr or lbs/hr) at peak and average loads, operating pressure, and application type. Our engineering team can provide a free consultation to accurately determine your requirements. - Q: What maintenance is required for electric steam boilers?

A: Electric boilers generally require less maintenance than fuel-fired units. Key tasks include regular water treatment, blowdown procedures, and periodic inspection of heating elements, controls, and safety devices. Annual professional inspection is highly recommended.

Lead Time and Fulfillment:

Manufacturers often maintain a stock of standard components to expedite production. For customized orders, detailed project management, including regular progress reports, ensures that delivery schedules are met efficiently. Global shipping logistics are typically handled, with options for sea freight or air freight depending on urgency.

Warranty and After-Sales Support:

Reliable electric steam boiler manufacturers provide comprehensive after-sales support, including:

- **Technical Assistance:** 24/7 helpline or online support for troubleshooting.

- **Spare Parts Availability:** Ready access to genuine spare parts to minimize downtime.

- **On-site Services:** Commissioning, preventative maintenance contracts, and emergency repair services.

- **Training:** Operator training programs to ensure safe and efficient boiler operation.

Conclusion

The industrial landscape is moving towards more sustainable, efficient, and reliable heating solutions. Electric steam boiler manufacturers are at the forefront of this transition, offering advanced technologies that deliver superior performance, reduce environmental impact, and lower operational costs. By focusing on stringent manufacturing processes, adherence to international standards, and a commitment to customer support, these manufacturers empower industries to achieve their production goals while meeting evolving regulatory and sustainability targets. Selecting the right partner is an investment in long-term operational excellence and environmental stewardship.

References

- U.S. Department of Energy. "Steam Boilers." Energy Efficiency and Renewable Energy.

- ASME Boiler and Pressure Vessel Code. Section I – Rules for Construction of Power Boilers.

- International Organization for Standardization. ISO 9001:2015 - Quality Management Systems.

- European Committee for Standardization. EN 12952: Water-tube boilers and auxiliary installations.

- Environmental Protection Agency (EPA). "Steam Boiler Efficiency and Performance."

-

Electric Steam Boiler Manufacturers: High-Efficiency Industrial SolutionsNewsAug.27,2025

-

Leading Electric Steam Boiler Manufacturers | Efficient IndustrialNewsAug.26,2025

-

Electric Steam Boiler Manufacturers: Efficient, Reliable SolutionsNewsAug.25,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable Industrial SolutionsNewsAug.24,2025

-

Reliable Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.23,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025