Leading Electric Steam Boiler Manufacturers & Industrial Solutions

The landscape of industrial heating is undergoing a transformative shift, driven by increasing demands for efficiency, sustainability, and operational safety. In this evolving environment, electric steam boiler manufacturers are at the forefront, pioneering solutions that address the critical needs of modern industries. Unlike traditional fossil fuel boilers, electric boilers offer a cleaner, more precise, and often more cost-effective pathway to meet diverse heating requirements, ranging from process heating in manufacturing to sterilization in healthcare.

I. Industry Trends and the Rise of Electric Boilers

The global industrial boiler market is projected to grow significantly, fueled by stringent environmental regulations, the push for decarbonization, and the rising adoption of automation. Specifically, the segment of electric boilers is experiencing robust growth due to their inherent advantages in reducing carbon footprints and improving operational efficiencies. Countries and corporations worldwide are committing to net-zero emissions, making electric heating solutions an increasingly attractive and often mandated choice. This trend is also influencing demand for related technologies like the gas steam boiler for sale (for transitional periods or specific regional energy mixes), advanced steam boiler heat exchanger units for enhanced energy recovery, and sophisticated thermostat for steam boiler systems for precise temperature control.

Recent market analyses indicate that the electric boiler segment is expanding at a Compound Annual Growth Rate (CAGR) of over 6% through 2028, driven by sectors like food & beverage, pharmaceuticals, textiles, and chemicals. This growth underscores a broader industry shift towards electrification as a primary strategy for energy independence and environmental compliance. Reputable electric steam boiler manufacturers are responding by investing heavily in R&D, developing more compact, efficient, and intelligent boiler systems.

II. Understanding Technical Parameters and Capabilities

When selecting industrial heating equipment, a thorough understanding of technical parameters is paramount. For electric boilers, key specifications include heating capacity (measured in kW or BTU/hr), operating pressure (typically 0.7 to 1.6 MPa for low pressure, up to 10 MPa or more for high pressure applications), operating temperature, voltage requirements (from 380V to 10kV for high-power units), and thermal efficiency. Modern electric boilers boast efficiencies often exceeding 98%, as nearly all electrical energy is converted into heat, eliminating stack losses associated with combustion boilers. This high efficiency translates directly into lower operating costs and reduced energy waste.

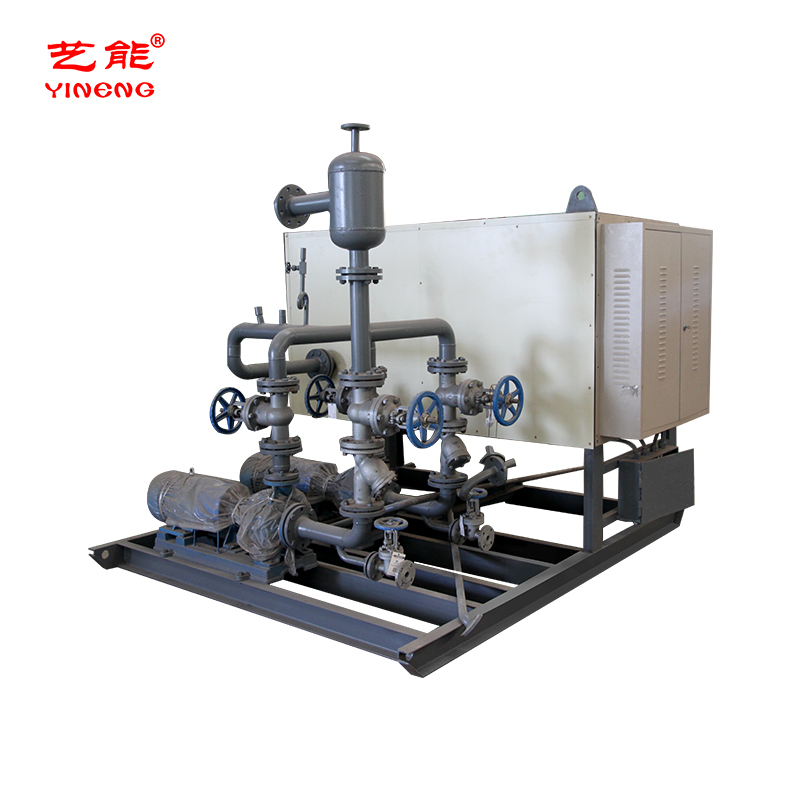

Consider the `Electric heating thermal oil boiler` from ynboilers.com as an example. While not a steam boiler, it exemplifies the high-efficiency, precise temperature control, and safety features characteristic of advanced electric heating solutions offered by leading electric steam boiler manufacturers. This type of boiler utilizes thermal oil as the heat transfer medium, offering advantages in high-temperature, low-pressure applications, avoiding the complexities of steam and condensate management. Its specifications typically include:

- Rated Power: Ranging from 100 kW to 20,000 kW (or even higher for custom large-scale projects).

- Operating Temperature: Up to 350°C (662°F) or beyond, suitable for processes requiring very high temperatures without high pressure.

- Voltage: Compatible with various industrial power grids (e.g., 380V, 400V, 480V, 3KV, 6KV, 10KV).

- Thermal Efficiency: Typically 95% - 99%. The near-perfect conversion of electrical energy into heat is a significant advantage.

- Design Pressure: Often lower than steam boilers, as thermal fluid systems operate at atmospheric or very low pressures even at high temperatures, enhancing safety.

- Heating Elements: High-grade, durable resistance heating elements (e.g., Incoloy 800) designed for long lifespan and consistent performance.

Comparing electric boilers to other types:

| Parameter | Electric Steam Boiler | Gas Steam Boiler | Wood Steam Boiler |

|---|---|---|---|

| Fuel Type | Electricity | Natural Gas, LPG | Biomass (wood chips, pellets) |

| Emissions (Direct) | Zero (at point of use) | CO2, NOx, SOx | CO2, Particulates, NOx |

| Thermal Efficiency | 98% - 99.5% | 80% - 92% | 70% - 85% |

| Operating Noise | Very Low | Moderate | Moderate to High |

| Space Footprint | Compact | Moderate | Large (requires fuel storage) |

| Fuel Storage Req. | None (direct grid connection) | Gas line (no storage needed) or LPG tanks | Significant space for wood storage |

| Maintenance | Lower (no combustion components) | Moderate (burner cleaning, stack maintenance) | Higher (ash removal, flue cleaning) |

| Startup Time | Very Fast | Fast | Moderate to Slow |

| Capital Cost | Moderate to High | Moderate | Moderate |

| Operational Cost | Depends on electricity tariffs | Depends on gas prices | Depends on wood availability/cost |

III. Diverse Application Scenarios

The versatility of electric heating solutions makes them indispensable across a multitude of industries. From the gentle heat required in pharmaceutical processes to the high temperatures needed for chemical reactions, electric steam boiler manufacturers provide tailored solutions. Here are some key application areas for both electric steam boilers and electric thermal oil boilers:

- Petrochemical Industry: For heating reactors, distillation columns, and various processing units where precise temperature control and explosion-proof designs are crucial. Electric thermal oil boilers are particularly well-suited for high-temperature applications without the risks associated with high-pressure steam.

- Food & Beverage: Sterilization of equipment, pasteurization, cooking, and drying processes. Electric boilers ensure clean steam production, essential for hygiene and product quality. For example, in dairies, uniform heat distribution for pasteurization is critical, which electric boilers excel at providing.

- Textile Industry: Dyeing, drying, and finishing processes. Consistent steam supply is vital for maintaining fabric quality and color consistency. The quiet operation and lack of emissions from electric boilers are also beneficial in these environments.

- Pharmaceuticals & Healthcare: Sterilization of medical instruments, autoclaves, and cleanroom humidity control. The demand for ultra-pure steam, free from combustion by-products, makes electric boilers the preferred choice.

- Rubber & Plastics: Vulcanization, molding, and extrusion processes. High-temperature stability and precise heat delivery are essential for material processing.

- Wood Processing: Kiln drying and veneer pressing. The ability to generate consistent heat profiles is critical for preventing warping and cracking. This is often handled by a specialized wood steam boiler for large-scale operations, but electric options offer better control and smaller footprint.

- Water Supply & Drainage (Wastewater Treatment): Heating tanks to facilitate biological processes or for dewatering sludge.

- Building Heating and HVAC: For large commercial and industrial buildings, providing space heating or hot water for domestic use.

IV. Core Technical Advantages of Electric Heating Solutions

The advantages of electric heating solutions provided by proficient electric steam boiler manufacturers extend beyond mere efficiency and environmental benefits. They encompass operational ease, safety, and long-term economic gains.

- Exceptional Energy Efficiency: As discussed, electric boilers convert nearly 100% of electrical energy into heat within the system. This eliminates heat losses associated with combustion (flue gas losses, radiation losses), making them significantly more efficient than fossil fuel alternatives. For an `Electric heating thermal oil boiler`, this means minimal energy waste and direct heat transfer to the thermal fluid.

- Zero Emissions at Point of Use: Electric boilers produce no direct greenhouse gas emissions (CO2, NOx, SOx) or particulate matter during operation. This is a critical advantage for compliance with environmental regulations and for achieving corporate sustainability goals. It also improves indoor air quality in facilities.

- Precise Temperature Control: With advanced PLC (Programmable Logic Controller) systems and sophisticated thermostat for steam boiler controls, electric units offer unparalleled temperature accuracy and stability. This is crucial for sensitive industrial processes where even slight temperature fluctuations can affect product quality or process integrity. Many systems integrate SCADA (Supervisory Control and Data Acquisition) for remote monitoring and control.

- Enhanced Safety: Without the need for fuel storage, combustion, or exhaust systems, the risks of explosions, fires, and carbon monoxide poisoning are significantly reduced. The absence of a flame eliminates hazards associated with burner operation. Modern electric boilers also incorporate multiple safety interlocks and alarms (e.g., over-temperature, over-pressure, low water/oil level, current overload).

- Lower Maintenance Requirements: The absence of complex burners, flues, and fuel handling systems means fewer moving parts and less wear and tear. This translates to reduced maintenance costs and downtime. Routine checks are typically simpler compared to a traditional steam boiler industrial.

- Quiet Operation: Electric boilers operate with minimal noise, contributing to a more comfortable and safer working environment.

- Compact Footprint: Electric heating elements and related controls can be integrated into relatively compact designs, saving valuable floor space in industrial facilities.

- Fast Response and Startup: Electric boilers can heat up quickly and respond rapidly to load changes, offering excellent flexibility for fluctuating process demands.

V. Manufacturer Comparison and Selection Criteria

Choosing the right electric steam boiler manufacturers is a strategic decision that impacts long-term operational efficiency, reliability, and support. While many companies offer heating solutions, discerning a top-tier manufacturer requires evaluating several key aspects:

- Reputation and Experience: Look for manufacturers with a proven track record, extensive experience in the industrial heating sector, and a strong client base. Companies with decades of operation, like those potentially manufacturing the robust weil mclain eg 40 steam boiler or innovative new electric models, often demonstrate deep industry knowledge.

- Certifications and Compliance: Ensure the manufacturer adheres to international quality and safety standards such as ISO 9001, ASME (American Society of Mechanical Engineers) codes for pressure vessels, CE marking for European markets, and local regulatory requirements. These certifications are non-negotiable for safety and performance.

- Technology and Innovation: Assess their commitment to R&D. Do they offer cutting-edge control systems, energy recovery options (like advanced steam boiler heat exchanger solutions), and smart automation features? Innovation indicates a forward-thinking company.

- Product Range and Customization: A broad product portfolio, including water tube steam boiler designs (for high pressure/capacity needs) or specialized thermal oil boilers, indicates versatility. The ability to provide customized solutions to meet unique process requirements is also a significant advantage.

- After-Sales Support and Service: Evaluate the availability of spare parts, technical support, installation services, and maintenance contracts. A manufacturer's commitment to long-term client relationships is crucial for operational continuity.

- Energy Efficiency Data and Guarantees: Request transparent data on boiler efficiency and potential energy savings. Reputable manufacturers will provide clear performance guarantees.

VI. Detailed Manufacturing Process of Advanced Electric Heating Equipment

The manufacturing of a high-quality `Electric heating thermal oil boiler` or an industrial electric steam boiler by leading electric steam boiler manufacturers involves a meticulous, multi-stage process designed to ensure durability, efficiency, and safety. This process often integrates advanced manufacturing techniques with rigorous quality control at every step.

Manufacturing Process Flow for an Electric Heating Thermal Oil Boiler:

- Design & Engineering:

- Conceptual Design: Based on client requirements (capacity, temperature, pressure, application), engineers develop initial concepts.

- Detailed Engineering: Utilizes CAD/CAM software for precise designs of pressure parts, heating elements, insulation, and control systems. Finite Element Analysis (FEA) may be employed for stress analysis.

- Material Selection: Crucial step. For pressure parts, high-grade boiler steel (e.g., SA-516 Grade 70 for pressure vessels, SA-106 Grade B for piping) is selected for its strength and corrosion resistance. Heating elements are typically made of high-nickel alloys like Incoloy 800 for excellent heat transfer and longevity. Insulation materials (e.g., rock wool, ceramic fiber) are chosen for their thermal properties.

- Material Preparation & Cutting:

- Raw materials (steel plates, pipes, flanges) are received and undergo initial quality checks for material composition and defects.

- Precision Cutting: CNC laser cutting or plasma cutting machines are used to cut steel plates and pipes to exact dimensions, minimizing waste and ensuring accuracy.

- Forming & Machining:

- Plate Rolling: Steel plates are rolled into cylindrical shells for the boiler body.

- Pipe Bending/Coiling: For thermal oil boilers, the heating coils are precisely bent and coiled to maximize heat exchange surface area. For steam boilers, tube sheets are drilled, and tubes are expanded.

- CNC Machining: Critical components like flanges, nozzles, and heating element mounting plates undergo CNC machining to ensure tight tolerances and perfect fit. This precision prevents leaks and ensures structural integrity.

- Welding & Assembly:

- Automated Welding: Robotic or automated welding processes (e.g., Submerged Arc Welding, TIG welding) are extensively used to ensure consistent, high-quality welds. Manual welding is used for intricate areas, performed by certified welders.

- Pressure Vessel Assembly: The boiler shell, tube sheets, and nozzles are assembled. For thermal oil boilers, the heating coils are carefully inserted and welded into the main structure.

- Non-Destructive Testing (NDT):

- After welding, critical weld seams undergo NDT to detect any internal flaws or cracks. Common methods include:

- Radiographic Testing (RT): X-rays or gamma rays to find internal defects.

- Ultrasonic Testing (UT): High-frequency sound waves to detect subsurface flaws.

- Magnetic Particle Testing (MPT) / Dye Penetrant Testing (DPT): For surface and near-surface defects.

- These tests ensure compliance with codes like ASME Boiler and Pressure Vessel Code.

- After welding, critical weld seams undergo NDT to detect any internal flaws or cracks. Common methods include:

- Hydrostatic Testing:

- The completed pressure vessel is filled with water and pressurized beyond its maximum operating pressure. This test verifies the structural integrity and leak-tightness of the boiler under stressed conditions.

- Insulation & Casing Installation:

- High-density thermal insulation is applied to minimize heat loss, significantly improving the boiler's overall energy efficiency.

- An outer casing (often painted and corrosion-resistant) is fitted, providing protection and aesthetic appeal.

- Control System Integration:

- The electrical control panel, PLC system, sensors (temperature, pressure, flow), and safety interlocks are integrated. Wiring is meticulously done according to electrical safety standards.

- This includes the integration of the thermostat for steam boiler (or thermal oil boiler) and other safety devices.

- Surface Treatment & Painting:

- Components undergo surface preparation (e.g., sandblasting) to remove impurities and enhance paint adhesion.

- Industrial-grade, corrosion-resistant paints are applied to protect the boiler from environmental elements and extend its service life. This is particularly important for an electric steam boiler industrial unit exposed to various operating conditions.

- Final Inspection & Quality Assurance:

- A comprehensive final inspection is performed, covering all aspects from dimensional accuracy to component functionality and safety features.

- All documentation, including material certificates, test reports, and operating manuals, is prepared.

- Packaging & Shipment:

- The boiler is carefully packaged to prevent damage during transit, often using robust crating or specialized shipping frames.

Through this meticulous process, top electric steam boiler manufacturers ensure a product lifespan often exceeding 15-20 years, with proper maintenance. The focus on high-quality materials and stringent manufacturing processes results in units that are not only energy-efficient but also highly reliable and safe, even for demanding sectors like petrochemicals (where corrosion resistance is paramount) and metallurgy.

VII. Custom Solutions and Project Implementation

Recognizing that every industrial application has unique requirements, leading electric steam boiler manufacturers offer comprehensive custom solutions. This bespoke approach ensures optimal integration, maximum efficiency, and adherence to specific operational parameters.

The Customization Process:

- Needs Assessment: An in-depth consultation to understand the client's heating requirements, including desired capacity, temperature, pressure, space constraints, existing infrastructure (e.g., availability of steam or thermal oil distribution networks), and specific industry standards (e.g., FDA for food/pharma, ATEX for hazardous environments).

- System Design & Engineering: Based on the assessment, engineers develop a tailored boiler system design. This might involve:

- Capacity Scaling: Designing a boiler with precise heating capacity (kW or tons of steam per hour) to match demand, avoiding oversizing or undersizing.

- Voltage Compatibility: Ensuring the boiler seamlessly integrates with the facility's electrical grid (e.g., 400V, 3KV, 6KV, 10KV systems).

- Integration with Existing Systems: Designing for compatibility with existing piping, control systems, and heat exchangers (e.g., a new steam boiler heat exchanger to optimize overall system efficiency).

- Footprint Optimization: Creating compact designs for facilities with limited space.

- Advanced Control Features: Incorporating specific automation protocols (Modbus, Profibus, Ethernet IP), remote monitoring capabilities, or integration with plant-wide DCS/SCADA systems.

- Material Specifications: Using specialized materials for corrosive environments or specific process fluids.

- Manufacturing & Quality Control: The customized design proceeds through the detailed manufacturing process outlined above, with rigorous quality checks at each stage to ensure the bespoke solution meets all specifications and standards.

- Installation & Commissioning Support: Manufacturers often provide supervised installation and commissioning services. This ensures the boiler is set up correctly, safety protocols are followed, and optimal performance is achieved from day one.

- Training & After-Sales Service: Comprehensive training for the client's operational staff and ongoing technical support, including preventive maintenance plans and rapid spare parts supply. This ensures the long-term reliability of a significant investment like an electric steam boiler industrial unit.

VIII. Real-World Application Cases and Customer Success Stories

The practical benefits of electric heating solutions are best illustrated through real-world applications. Leading electric steam boiler manufacturers can often share compelling case studies demonstrating significant improvements in efficiency, environmental compliance, and operational savings.

- Case Study 1: Large Pharmaceutical Plant in Europe

A major pharmaceutical manufacturer needed to replace outdated fossil fuel boilers to meet strict emissions targets and enhance steam purity for sterilization processes. They opted for an array of high-capacity electric steam boilers from a leading manufacturer.- Challenge: Achieve ultra-pure, consistent steam for sensitive processes and reduce carbon emissions.

- Solution: Installation of three 5 MW electric steam boilers.

- Outcome:

- Achieved zero direct CO2 emissions on-site, contributing to their corporate sustainability goals.

- Steam quality improved, reducing product contamination risks.

- Operational noise levels significantly dropped, enhancing the working environment.

- Reported 18% reduction in overall energy costs due to high boiler efficiency and favorable electricity tariffs for peak shaving.

- Case Study 2: Chemical Processing Facility in North America

A specialty chemical producer required a high-temperature heating solution for a new reactor, demanding precise temperature control and enhanced safety without the complexities of high-pressure steam.- Challenge: Achieve stable temperatures up to 320°C for a chemical reaction in a hazardous area, ensuring maximum safety.

- Solution: Implementation of a custom-designed `Electric heating thermal oil boiler` system (2 MW capacity).

- Outcome:

- Precise temperature stability maintained within ±1°C, leading to consistent product quality.

- Elimination of high-pressure steam lines reduced inherent safety risks and simplified compliance.

- Reduced maintenance burden compared to previous boiler systems.

- The compact design integrated seamlessly into the existing plant layout.

- Case Study 3: Food Processing Plant in Asia

A major snack food manufacturer sought to upgrade their drying and cooking processes, looking for a more efficient and reliable steam source.- Challenge: Improve energy efficiency and reduce operational downtime.

- Solution: Replaced an old gas steam boiler for sale with a new, highly efficient electric boiler setup.

- Outcome:

- Achieved a verified 15% reduction in energy consumption for the heating processes.

- Boiler uptime increased to 99.5%, significantly reducing production interruptions.

- Simplified operations due to automated controls and minimal manual intervention.

IX. Trustworthiness: Ensuring Confidence in Your Investment

Trust is the bedrock of any significant industrial investment. Reputable electric steam boiler manufacturers build trust through transparent practices, robust support, and unwavering commitments.

- FAQ Module:

Q1: What is the typical lifespan of an electric industrial boiler?

A: With proper installation, regular maintenance, and adherence to operating guidelines, high-quality electric industrial boilers, including water tube steam boiler designs, typically have a service life of 15 to 25 years. Key factors include material quality (e.g., boiler steel such as SA-516 Grade 70) and design robustness.Q2: How does an electric boiler achieve high temperatures without high pressure?

A: For steam boilers, pressure is inherent to steam generation. However, for thermal oil boilers like the `Electric heating thermal oil boiler`, high temperatures (e.g., 350°C) are achieved by heating specialized thermal transfer fluids that have very high boiling points, allowing them to operate at near-atmospheric pressure, significantly enhancing safety and simplifying design compared to high-pressure steam systems.Q3: Are electric boilers suitable for outdoor installation?

A: While many industrial electric boilers are designed for indoor use, custom weatherproof enclosures can be provided by electric steam boiler manufacturers for specific outdoor installations. Factors like ambient temperature, humidity, and corrosive environments need to be considered in the design.Q4: What are the main maintenance requirements for an electric boiler?

A: Compared to combustion boilers, maintenance is simpler. It primarily involves routine inspection of heating elements, electrical connections, control systems (including the thermostat for steam boiler), insulation integrity, and pressure/temperature sensors. Water quality management is crucial for steam boilers to prevent scaling.Q5: What are the typical delivery and installation lead times?

A: Delivery times vary based on boiler size, complexity, and customization, typically ranging from 8 to 20 weeks. Installation and commissioning can take an additional 1-4 weeks, depending on site readiness and system integration requirements.Q6: Can electric boilers be integrated with renewable energy sources?

A: Absolutely. Electric boilers are ideal for integration with renewable energy sources like solar PV or wind power, as they directly utilize electricity. This synergy further enhances the environmental credentials and can lead to significant operational cost savings if renewable energy tariffs are favorable.Q7: What is the benefit of a steam boiler heat exchanger in an electric boiler system?

A: While electric boilers are highly efficient, a steam boiler heat exchanger can be integrated into the overall plant system to recover waste heat from other processes (e.g., condensate return, flue gas from other combustion units if present) and preheat boiler feedwater or thermal oil. This maximizes the plant's overall energy efficiency and reduces the boiler's energy input requirements, optimizing the entire system. - Delivery Cycle and Project Management:

A reputable manufacturer will provide a clear, detailed project timeline from design approval to final commissioning. This includes milestones for material procurement, manufacturing, quality control checkpoints, shipping, and on-site support. Transparent communication throughout the process is key.

- Quality Assurance and Warranty Commitments:

Manufacturers should offer robust warranties covering parts and workmanship, typically ranging from 12 to 24 months after installation or 18 months after shipment. This reflects confidence in their product quality and manufacturing processes (e.g., adherence to ISO standards, use of high-grade materials, and stringent testing protocols like hydrostatic and NDT). Compliance with international standards such as ASME, CE, and local safety regulations (e.g., for pressure vessels) is a fundamental guarantee of safety and performance.

- Customer Support and Service Network:

Access to a responsive and knowledgeable customer support team is vital. This includes remote technical support, on-site service engineers for troubleshooting and maintenance, and a readily available supply of genuine spare parts. Companies that invest in a global service network demonstrate a higher level of commitment to their clients.

By prioritizing these elements of trustworthiness, industries can make informed decisions when partnering with electric steam boiler manufacturers, ensuring a reliable and sustainable heating solution for years to come.

The transition to electric heating solutions marks a pivotal moment in industrial sustainability. As the demand for cleaner, more efficient, and safer energy sources continues to grow, electric steam boiler manufacturers stand ready to deliver cutting-edge technologies that empower industries to meet their operational goals while minimizing their environmental impact. The meticulous manufacturing processes, adherence to global standards, and commitment to comprehensive customer support underscore the reliability and long-term value offered by these innovative heating systems.

For further insights into industrial boiler technology and clean energy trends, consider exploring resources from authoritative bodies and industry publications. For instance, the Boiler Industry Association often publishes reports on efficiency and regulatory compliance, while academic journals delve into the specifics of heat transfer and material science for industrial applications. Understanding these broader trends can help industries make informed decisions on their energy investments.

References:

- "Trends in Industrial Decarbonization and Electrification." Industrial Energy Efficiency Forum. Available at: https://www.ieeforum.org/trends-decarbonization

- "Advances in High-Efficiency Electric Boilers for Process Heating." Journal of Energy Engineering. Available at: https://www.energyengineeringjournal.com/electric-boilers-advances

- "The Role of Industrial Boilers in Achieving Net-Zero Emissions." Global Clean Energy Forum. Available at: https://www.cleanenergyforum.org/boiler-net-zero

-

Leading Electric Steam Boiler Manufacturers & Industrial SolutionsNewsAug.09,2025

-

Industrial Electric Steam Boiler Manufacturers | Efficient SolutionsNewsAug.08,2025

-

Industrial Electric Steam Boilers | Top Manufacturers & SuppliersNewsAug.07,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025