Boilers Designed for Efficient Production of Rubber Goods and Materials

The Role of Boilers in Rubber Product Manufacturing

In the rubber manufacturing industry, the efficiency and quality of production are paramount. One critical component that underpins this production is the boiler system. Boilers play a vital role in heating, curing, and processing rubber products, ensuring that they meet the necessary quality standards and specifications. This article will explore the significance of boilers in rubber manufacturing, their operational principles, and the benefits they bring to the industry.

Understanding the Manufacturing Process

Rubber products undergo several stages in their manufacturing process, including compounding, molding, and curing. Each of these stages requires specific temperatures and controlled environments to achieve the desired characteristics in the finished product. For instance, during the curing stage, heat is applied to the rubber compound to facilitate cross-linking of the rubber chains, which enhances its strength, elasticity, and durability. This is where boilers come into play.

Types of Boilers Used in Rubber Manufacturing

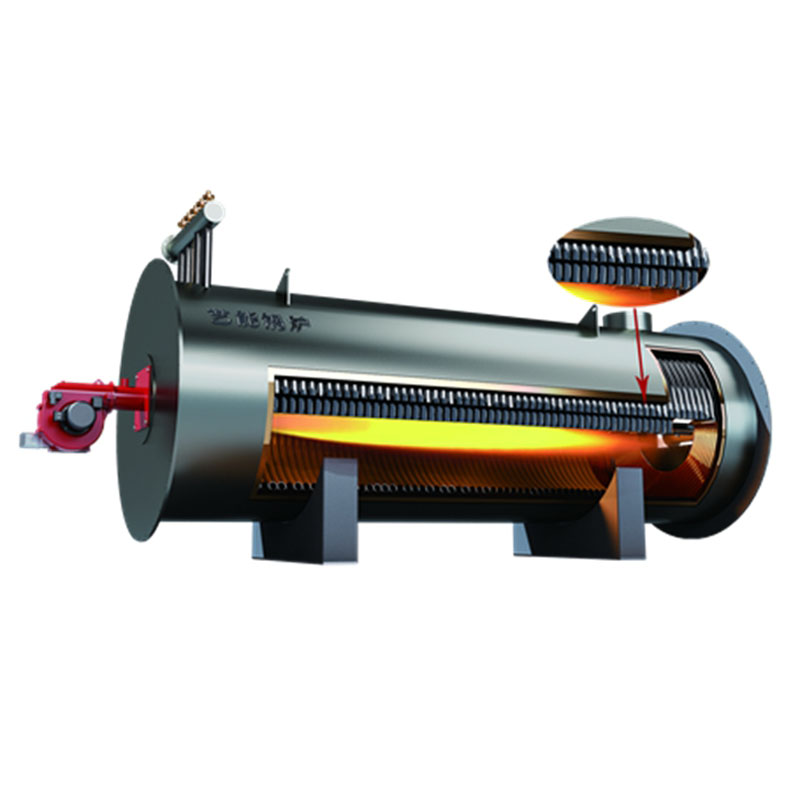

The types of boilers commonly used in rubber manufacturing include steam boilers and thermal oil heaters.

1. Steam Boilers Steam boilers generate steam by heating water, which is then used to supply heat to various processes in the rubber plant. The steam is particularly useful in curing rubber products, where it helps maintain the required temperatures for the optimal chemical reactions to occur. Efficiency is key when it comes to steam boilers, as they need to operate continuously with minimal downtime.

2. Thermal Oil Heaters In some cases, thermal oil heaters are preferred due to their ability to provide higher temperature control and flexibility. These systems circulate thermal oil through heated coils, providing even heat distribution to the rubber products. They are often used in applications that require specific heating profiles and faster temperature adjustments.

Benefits of Using Boilers in Rubber Production

boiler for rubber products

1. Improved Quality Control Boilers provide the consistent and precise temperature control needed during the curing process. This ensures that the rubber products attain the desired hardness and flexibility. Consistency in heating reduces variances in product quality, resulting in better end products that meet industry standards.

2. Enhanced Cost Efficiency By utilizing modern boiler technologies, manufacturers can achieve higher efficiency rates, leading to lower fuel consumption and reduced operational costs. This is particularly crucial in an industry known for its rigorous competition and economic pressures.

3. Increased Production Capacity Reliable boiler systems enable rubber manufacturers to increase their production capacity. With high-efficiency boilers, plants can run longer production cycles without downtime for maintenance. This scalability is essential for meeting market demands and fulfilling large orders.

4. Environmental Considerations Modern boilers are designed to minimize emissions and environmental impact. By complying with stringent environmental regulations, rubber manufacturers can reduce their carbon footprint and contribute to sustainability efforts within the industry.

Maintenance and Safety

While boilers are integral to rubber manufacturing, they require regular maintenance to operate safely and efficiently. A well-maintained boiler minimizes the risk of breakdowns and ensures compliance with safety regulations. Regular inspections, cleaning, and updating safety features are crucial for prolonging boiler life and optimizing performance.

Conclusion

In conclusion, boilers are an essential component in the manufacturing of rubber products, significantly impacting quality, efficiency, and production capacity. By employing advanced boiler systems, rubber manufacturers can not only improve their operational processes but also meet the ever-growing demands of the industry. As technology continues to evolve, the role of boilers in rubber production will undoubtedly expand, paving the way for innovative, efficient, and sustainable manufacturing practices. Investing in modern boiler systems is, therefore, a strategic move for any rubber manufacturer looking to thrive in today’s competitive marketplace.

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025